Toughening agent composition and application thereof, HIPS resin, ABS resin and preparation method thereof

A technology of a toughening agent and a composition is applied in the field of a method and the ABS resin prepared by the method, and can solve the problems of single particle size, difficulty in taking into account both impact resistance and gloss, and low impact resistance of the resin. Achieve high impact strength, broad industrial application prospects, and high surface gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0088] This preparation example is used to illustrate the preparation of the low-cis polybutadiene rubber and styrene-butadiene rubber of the present invention.

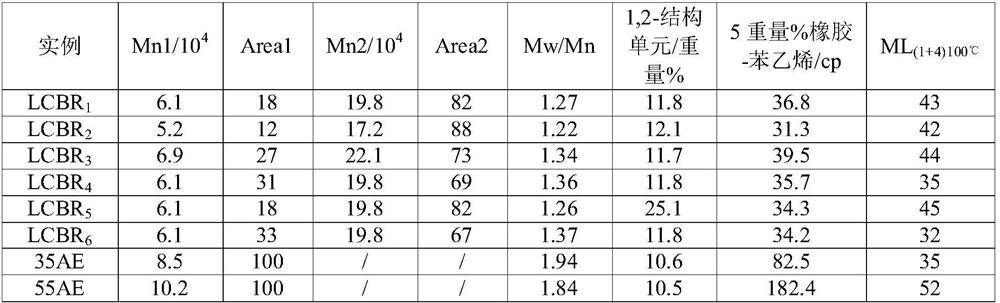

[0089] (1) Preparation of low cis polybutadiene rubber

[0090] Use anionic batch polymerization process to carry out butadiene solution polymerization, then use silicon tetrachloride for coupling, use carbon dioxide aqueous solution (the molar ratio of carbon dioxide and n-butyllithium is 1:1) to terminate, and then add low-cis polybutylene The 1520 and 1076 composite antioxidants (1520:1076=1:1, weight ratio) of diene rubber weight 0.3% by weight are prepared respectively to obtain low-cis polybutadiene rubber LCBR 1 -LCBR 6 , respectively measured the structure and performance of the obtained low-cis polybutadiene rubber, and the specific results are shown in Table 1.

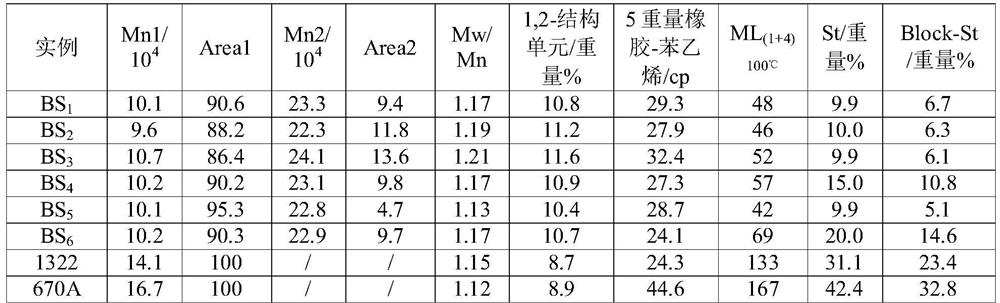

[0091] (2) Preparation of styrene-butadiene rubber

[0092] Using an anionic batch polymerization process, carry out solution polymerization of...

Embodiment 1

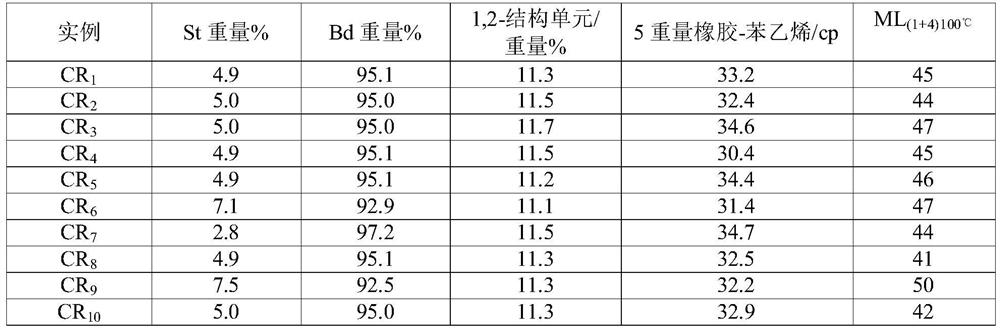

[0094] This embodiment is used to illustrate the preparation of toughening agent composition of the present invention

[0095] Low cis polybutadiene rubber LCBR 1 Solution and styrene butadiene rubber BS 1 The solution is mixed according to the dry rubber weight ratio of low-cis polybutadiene rubber and styrene-butadiene rubber at 1:1 to obtain a toughening agent composition solution R 1 , the R 1 Carry out steam condensation and desolvation treatment to obtain the toughening agent composition CR 1 , and determine the toughener composition CR 1 The structure and performance of the specific results are shown in Table 3.

Embodiment 2-5

[0097] This embodiment is used to illustrate the preparation of toughening agent composition of the present invention

[0098] Adopt the method similar to embodiment 1 to prepare toughening agent composition, difference is, the kind of low-cis polybutadiene rubber or styrene-butadiene rubber that adopts is different from embodiment 1, and all the other are all the same as embodiment 1, A toughening agent composition is prepared, specifically:

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com