Low cis-polybutadiene rubber, preparation method and application thereof, HIPS resin and preparation method thereof

A cis-polybutadiene and polybutadiene rubber technology, applied in the field of polybutadiene rubber, can solve the problems of turbidity of styrene solution, high APHA chromaticity, high yellow index of HIPS resin, and achieve excellent impact resistance , low yellow index, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

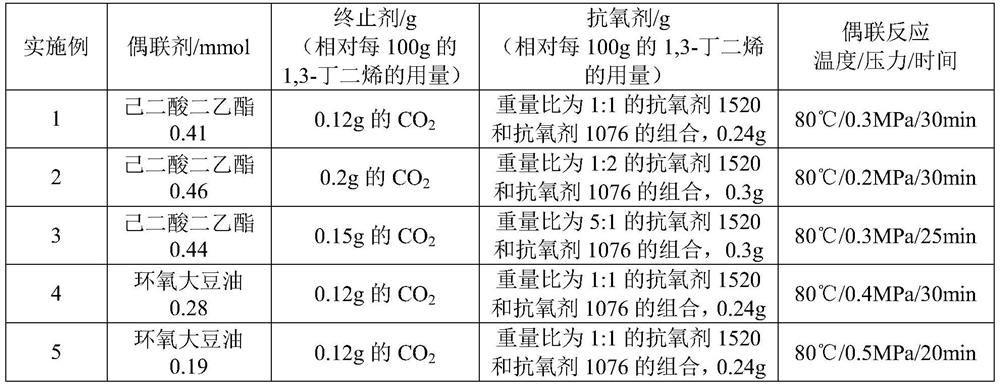

[0080] According to a preferred embodiment of the present invention, the antioxidant is 4,6-bis(octylthiomethyl)o-cresol (antiaging agent 1520) and β-(3,5-di-tert-butyl-4 -A combination of n-octadecanyl hydroxyphenyl) propionate (antiaging agent 1076), and in said combination, said 4,6-bis(octylthiomethyl) o-cresol and said β-( The weight ratio of n-octadecyl 3,5-di-tert-butyl-4-hydroxyphenyl)propionate is 0.5-5:1, more preferably 1:1.

[0081] Preferably, the weight ratio of the antioxidant to the 1,3-butadiene monomer is 0.1-0.6:100, preferably 0.1-0.4:100, more preferably 0.2-0.3:100.

[0082] In the method described in the second aspect of the present invention, in order to extract the low-cis polybutadiene rubber from the reaction product that terminates or introduces an oxidant, it may also include subjecting the reaction product to steam condensation treatment to remove the solvent , and drying to remove moisture and other post-processing steps known in the art, the pr...

specific Embodiment approach 1

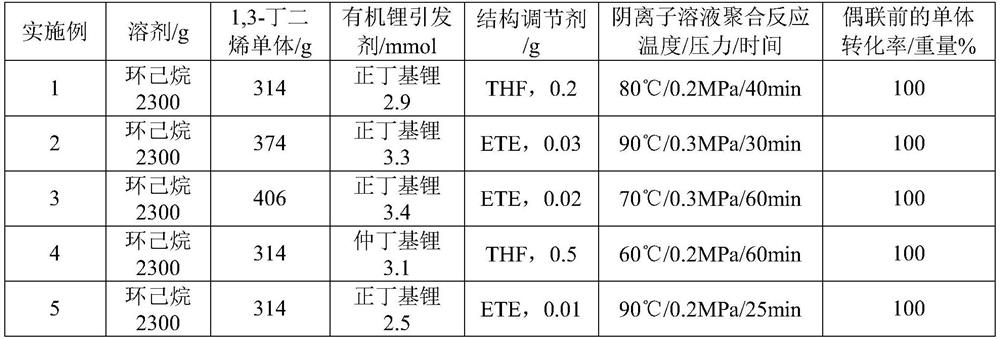

[0085] The method includes:

[0086] (1) Under a protective atmosphere, in a non-polar hydrocarbon solvent, in the presence of an organolithium initiator and a structure regulator, the 1,3-butadiene monomer is subjected to anionic solution polymerization reaction to 1,3- The butadiene monomer is completely converted to obtain a polybutadiene active chain with a number average molecular weight of 100,000-130,000, preferably 105,000-125,000, more preferably 110,000-120,000; the 1,3-butane The molar ratio of the diene monomer to the organolithium initiator is 1850-2450:1, preferably 1950-2350:1;

[0087] (2) In the presence of a halogen-free coupling agent, the product of the anionic solution polymerization reaction is subjected to a coupling reaction to obtain a polybutadiene active chain with a bimodal distribution of the number average molecular weight, the coupling agent and the organic The molar ratio of lithium initiator used is 0.07-0.16:1, preferably 0.08-0.15:1;

[008...

specific Embodiment approach 2

[0090] The method includes:

[0091] (1) Under a protective atmosphere, in a non-polar hydrocarbon solvent, in the presence of an organolithium initiator and a structure regulator, the 1,3-butadiene monomer is subjected to anionic solution polymerization reaction to 1,3- The butadiene monomer is completely converted to obtain a polybutadiene active chain with a number average molecular weight of 100,000-130,000, preferably 105,000-125,000, more preferably 110,000-120,000; the 1,3-butane The molar ratio of the diene monomer to the organolithium initiator is 1850-2450:1, preferably 1950-2350:1;

[0092] (2) In the presence of a halogen-free coupling agent, the product of the anionic solution polymerization reaction is subjected to a coupling reaction to obtain a polybutadiene active chain with a bimodal distribution of the number average molecular weight, the coupling agent and the organic The molar ratio of lithium initiator is 0.07-0.16:1, preferably 0.08-0.15:1;

[0093] (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| izod impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com