Device for achieving rapid dividing to form dry and wet areas for maintaining interior of liquid conveying pipeline

A technology for conveying pipelines and liquids. It is applied in the direction of pipe components, pipes/pipe joints/pipes, mechanical equipment, etc. It can solve problems affecting maintenance efficiency and quality, affecting construction period, and threatening personal safety, etc., so as to improve maintenance work efficiency and Maintenance quality, avoid electric shock accidents, and ensure the effect of maintenance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

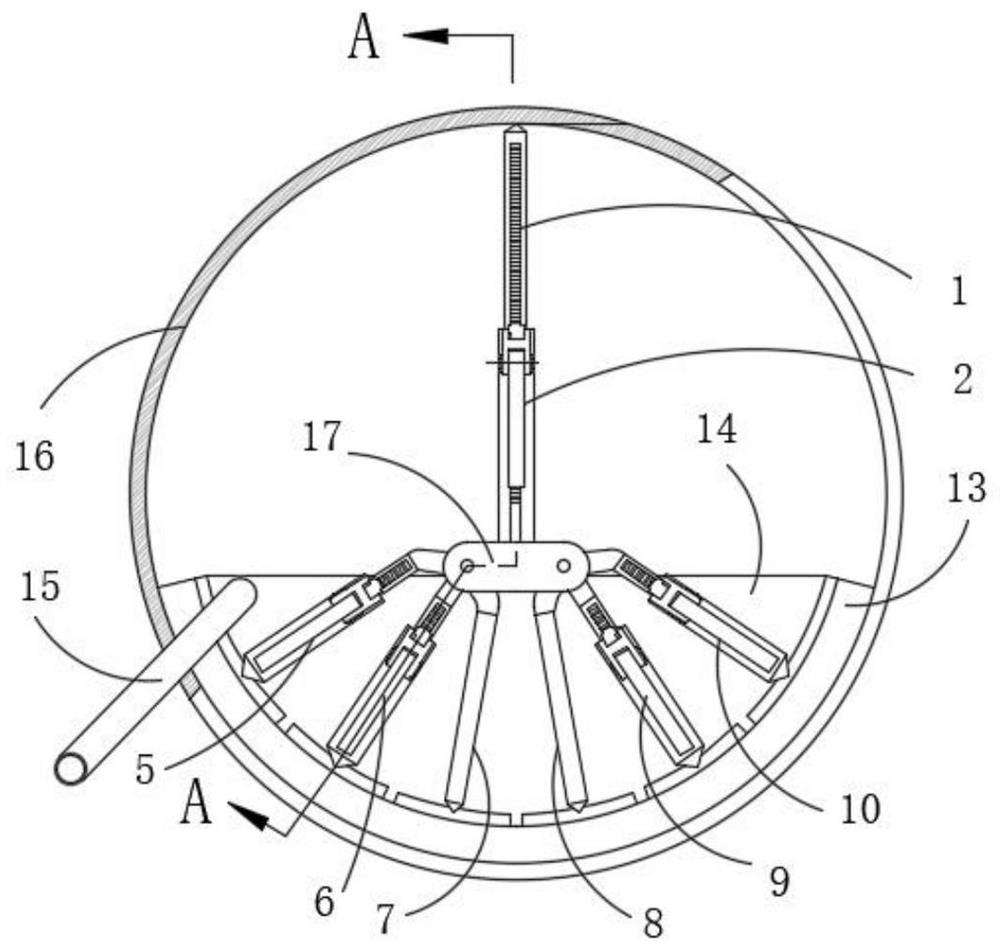

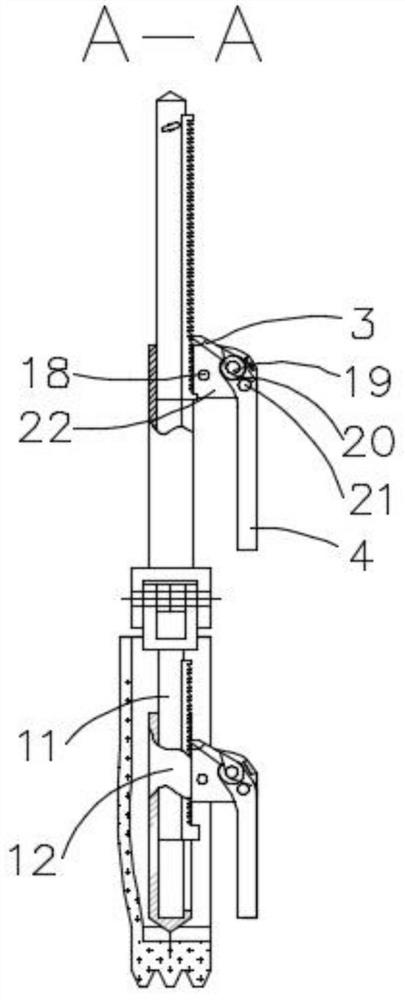

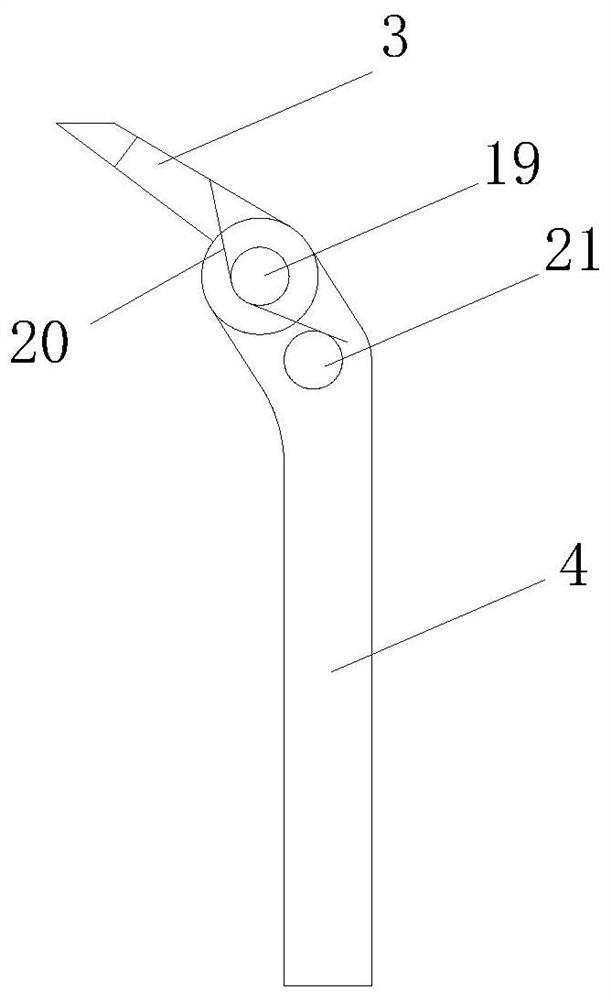

[0027] From Figure 1-3 It can be seen that the device for quickly separating and forming dry and wet areas for internal maintenance of liquid delivery pipelines in this embodiment includes an upper support component, a lower support component and a water retaining component. The upper support component includes an upper support movable ejector rod 1, an upper support fixed Sleeve 2, top tooth 3, handle 4, stop pin 18, top tooth pin 19, butterfly spring 20, handle pin 21 and handle connecting seat 22;

[0028] The upper support movable mandrel 1 is free to expand and contract in the upper support fixed sleeve 2, the upper top of the upper support movable mandrel 1 is processed into a cone, and one side of the upper support movable mandrel 1 is fixedly welded with a rack along the axial direction. The support fixed sleeve 2 is set on the outer surface of the upper support movable mandrel 1, one end of the upper support fixed sleeve 2 is fixedly welded with a connecting seat 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com