Pre-encapsulated frame edge rib reinforcing structure and manufacturing method thereof

A technology for strengthening structures and manufacturing methods, applied in the fields of semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor/solid-state device components, etc. The effect of import intent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

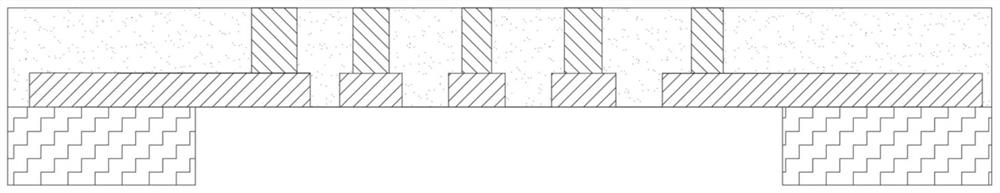

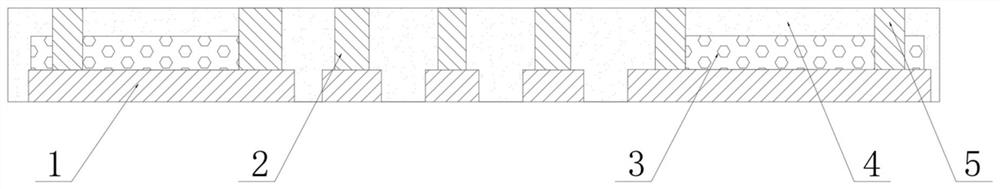

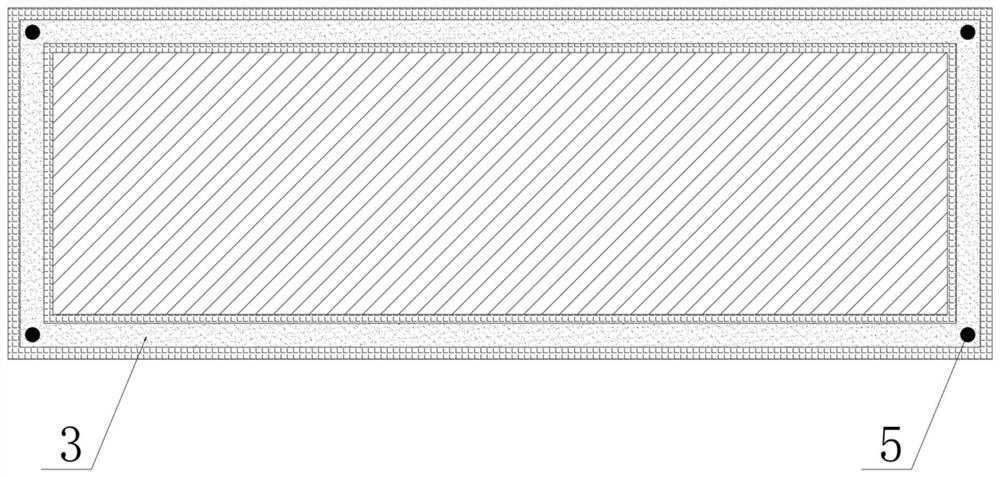

[0031] Such as figure 2 , image 3 As shown, a pre-encapsulated frame edge reinforcement structure in this embodiment includes a first graphic layer 1, a second graphic layer 2 and a reinforcing material layer 3 are arranged on the first graphic layer 1, and the The reinforcing material layer 3 is located at the peripheral edge of the second pattern layer 2, and the periphery of the first pattern layer 1, the second pattern layer 2 and the reinforcing material layer 3 is encapsulated with a plastic encapsulant 4;

[0032] The first graphic layer 1 is provided with metal pillars 5 at the four corners of the reinforcing material layer 3, and the reinforcing material layer 3 is fixed through the metal pillars 5;

[0033] The upper surface of the second graphic layer 2 and the metal post 5 is flush.

[0034] Its manufacturing method is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com