Photoelectric device and preparation method thereof

A kind of optoelectronic device and device technology, applied in the direction of electric solid-state device, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems hindering the development and application of quantum dot electroluminescence display technology, achieve long service life, reduce excitons Quenching, high luminous efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

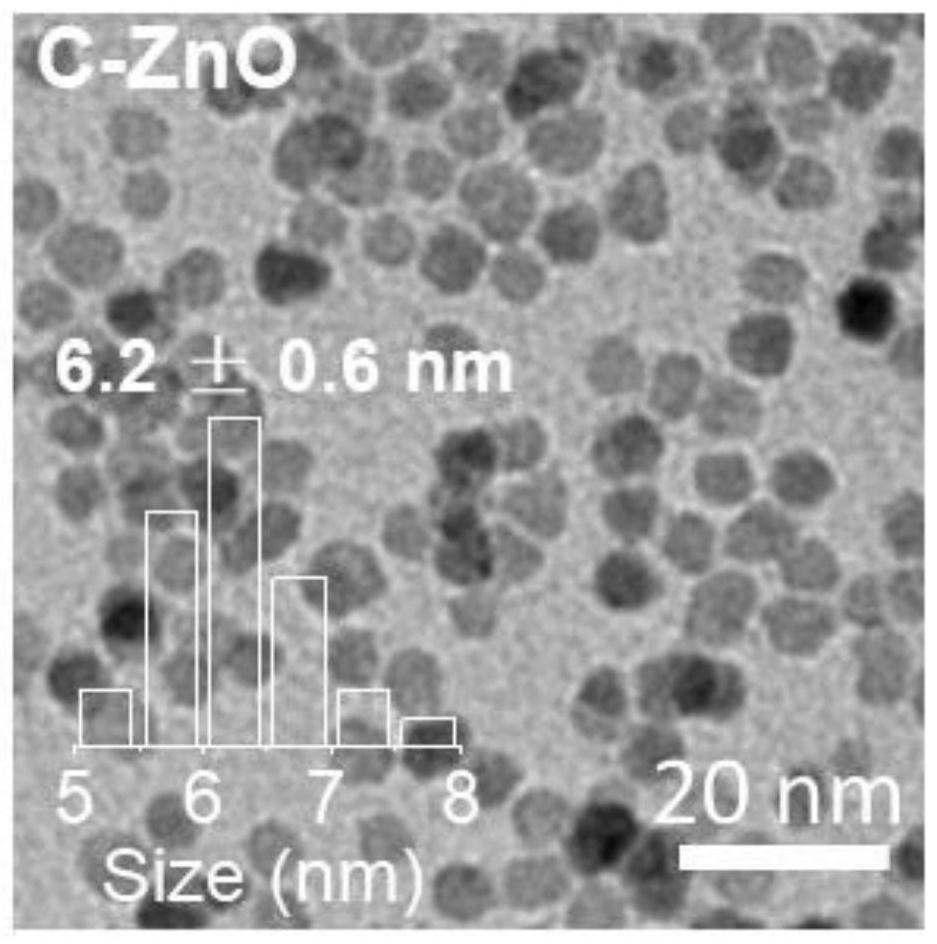

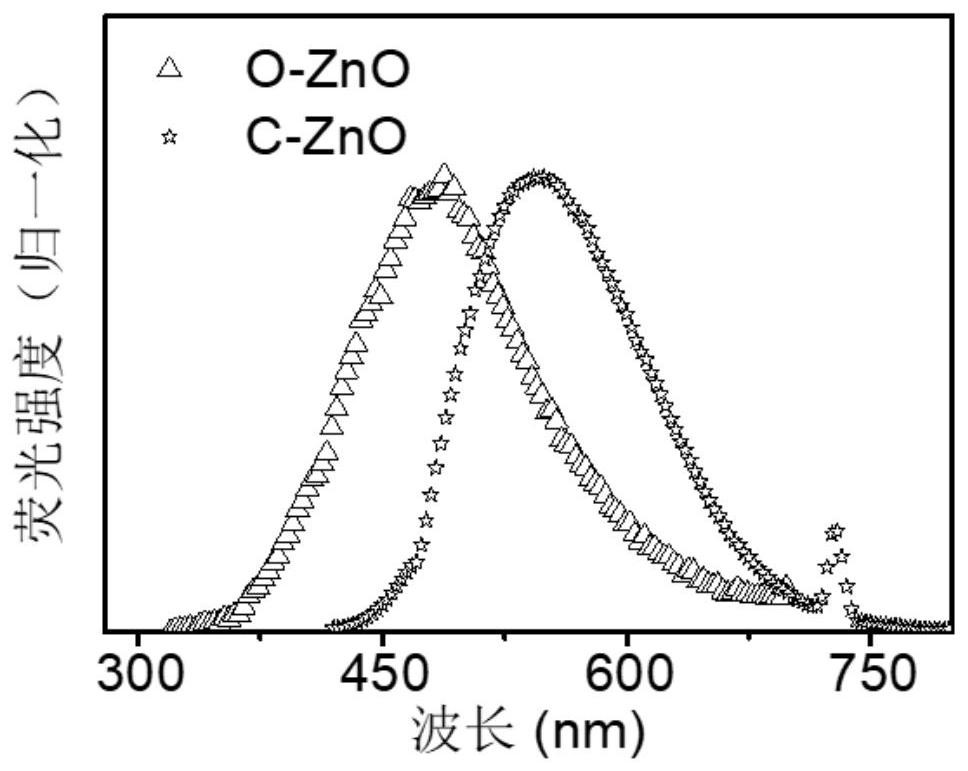

[0049] The present invention also provides a method for preparing a photoelectric device, comprising the following steps: S1, providing a substrate, setting a first zinc oxide nanocrystal solution on the substrate, annealing to form a first electron transport layer; S2, forming a first electron transport layer on the first electron transport layer The second zinc oxide nanocrystal solution is placed on the substrate without annealing, and the second electron transport layer is formed after drying; or, S1, the substrate is provided, the second zinc oxide nanocrystal solution is placed on the substrate, and the second electron transport layer is formed by annealing treatment; S2, setting the first zinc oxide nanocrystal solution on the second electron transport layer, without annealing, forming the first electron transport layer after drying; wherein, the first zinc oxide nanocrystal has a first size, and the first zinc oxide nanocrystal The existence of the first defect state em...

Embodiment 1

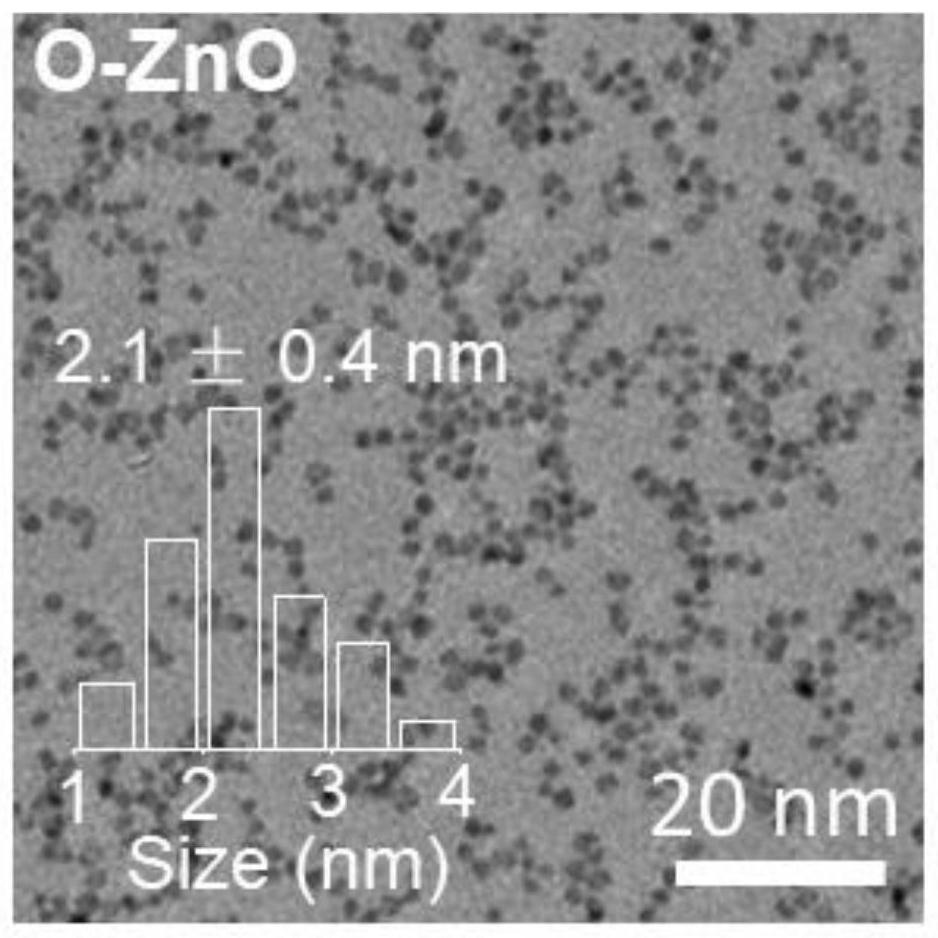

[0059] (1) Synthesis of the first zinc oxide nanocrystals:

[0060] Synthesis of the third zinc oxide nanocrystal: Weigh 1mmol zinc acetate, dissolve it in 10mL dimethyl sulfoxide (DMSO), stir and dissolve at 50°C; continue to weigh 4mmol lithium hydroxide, and ultrasonically assist in dissolving it in 40mL ethanol solution; LiOH was completely dissolved, and it was directly injected into the DMSO solution containing zinc acetate, and reacted at 50°C for 1h.

[0061] The third surface treatment of zinc oxide nanocrystals: After the reaction is finished, add 2mmol acetic acid to neutralize the excess alkali in the reaction, and then add 0.5mmol Mg(Ac) to the system 2 DMSO (~5mL) solution, continue to react at 50°C for 30min.

[0062] Purification of the first zinc oxide nanocrystal: Take 5 mL of the above reaction stock solution, add 20 mL of ethyl acetate, centrifuge, pour off the supernatant; dissolve the precipitate with 1 mL of ethanol, add 3 mL of ethyl acetate, and centr...

Embodiment 2

[0075] The difference between this embodiment and Example 1 is only: (1) the synthesis of the first zinc oxide nanocrystal: zinc acetate and Mg(Ac) 2 The ratio of the amount of substance is 5:1. The first zinc oxide nanocrystals with an average size of 2.2 nm were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap