Welding workbench

A technology of workbench and connecting part, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems that the positioning pin cannot be inserted into the positioning hole, affect the welding effect of the workpiece, and the position deviation of the turning frame, etc., to achieve Guaranteed welding fixing effect, good positioning and fixing effect, and guaranteed fixing position effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below according to the accompanying drawings and specific embodiments.

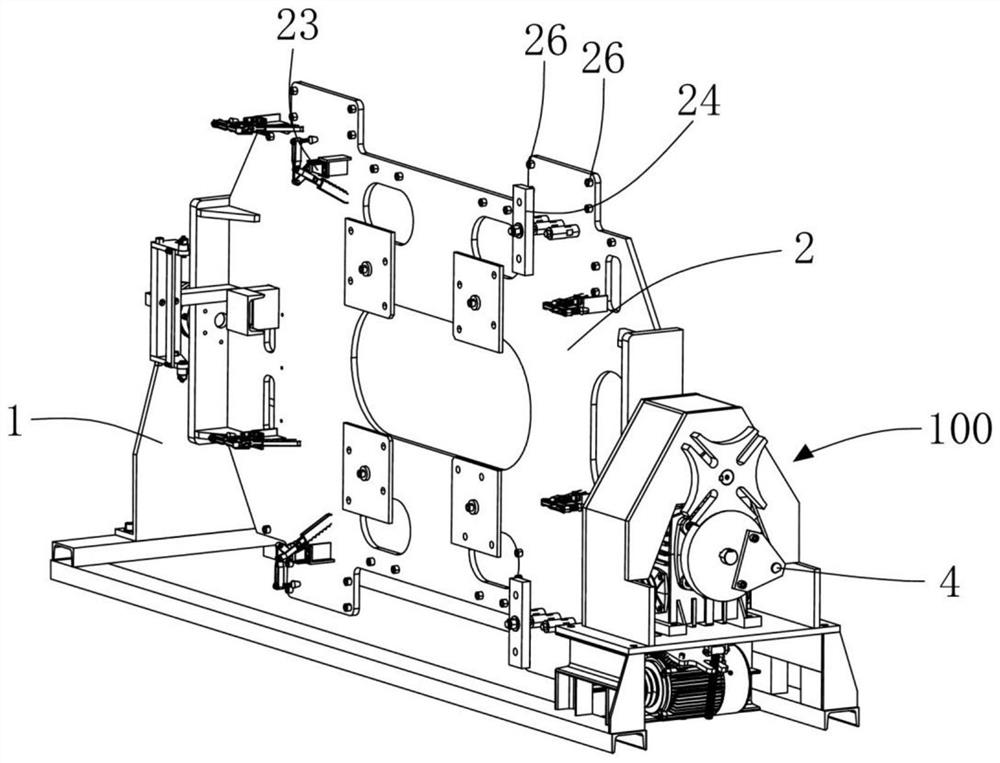

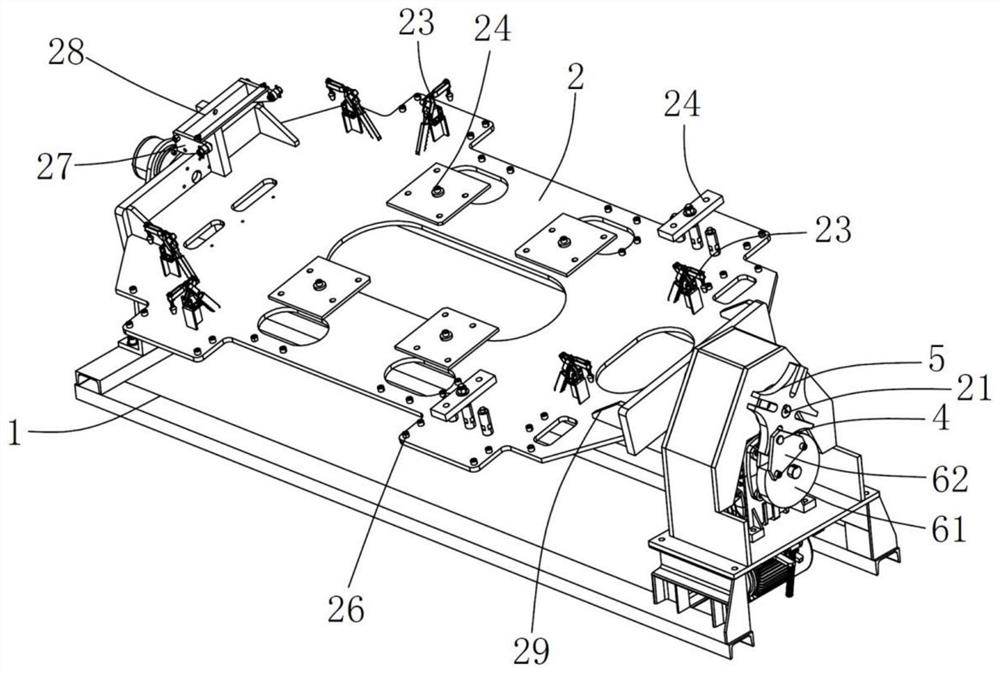

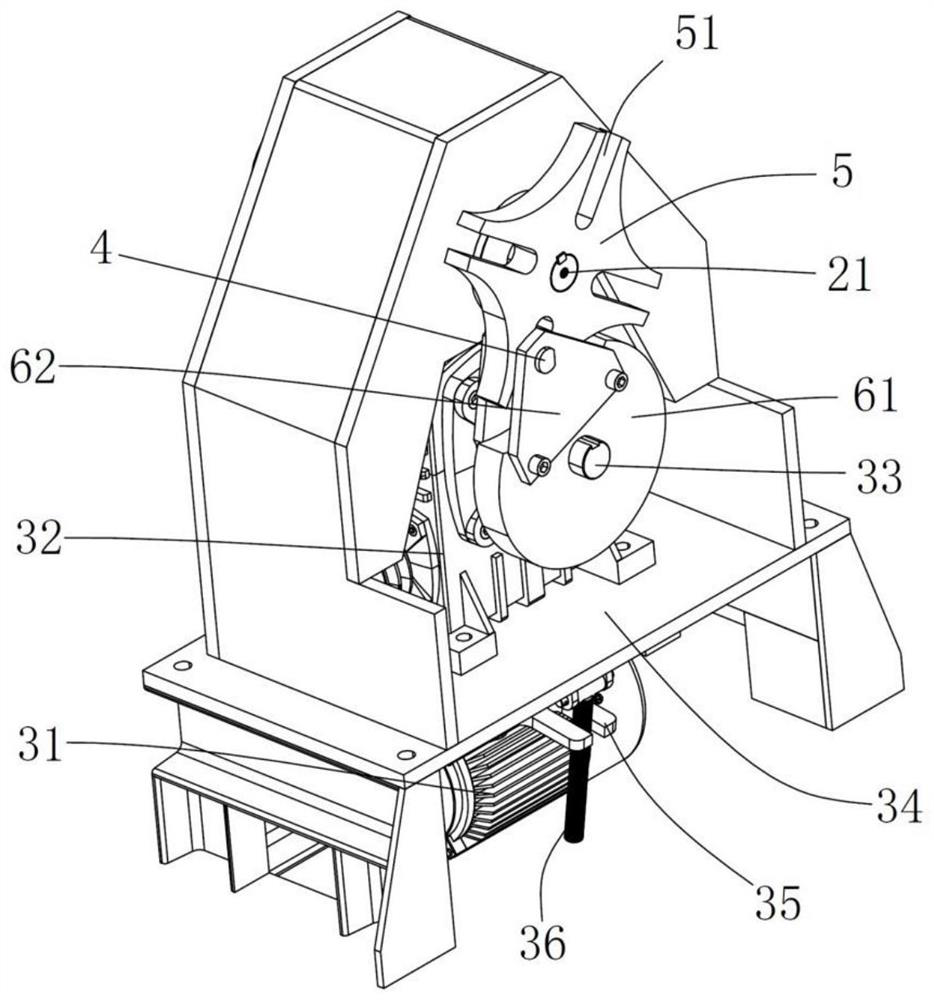

[0026] Depend on figure 1 , image 3 , Figure 4 and Figure 5 As shown, a welding workbench includes a fixed frame 1 and an overturning frame 2 rotatably fixed on the fixed frame 1. The overturning frame 2 and the driver with self-locking function are connected through a linkage mechanism 100. The driver includes a motor 31 and a deceleration Box 32 , the output shaft 33 of the reduction box 32 is linked with the second transmission member 4 , and the axis of the output shaft 33 of the reduction box 32 is located directly below the rotation axis of the reversing frame 2 .

[0027] The input shaft of the reduction box 32 and the rotor shaft of the motor 31 are driven by a belt or a chain. The reduction box 32 and the motor 31 are respectively located on the upper and lower sides of the mounting plate 34. The front side of the motor 31 is hinged and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com