Intelligent multiphase flow self-circulation energy-saving dust suppression and removal device

A dust removal device and intelligent technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of high energy consumption, low efficiency, high maintenance cost, etc., and achieve the effects of reducing maintenance costs, solving dust problems, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

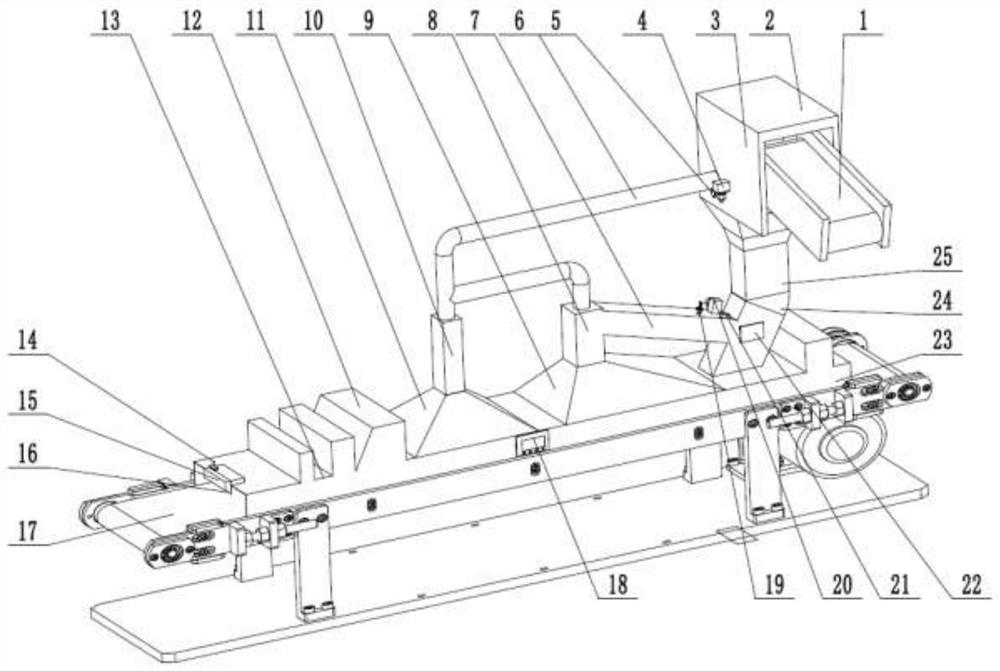

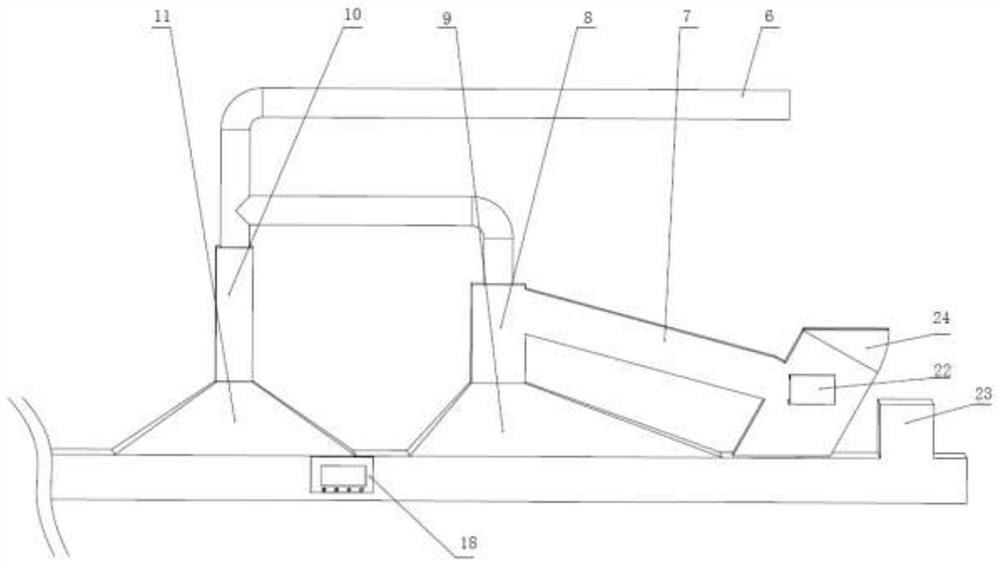

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

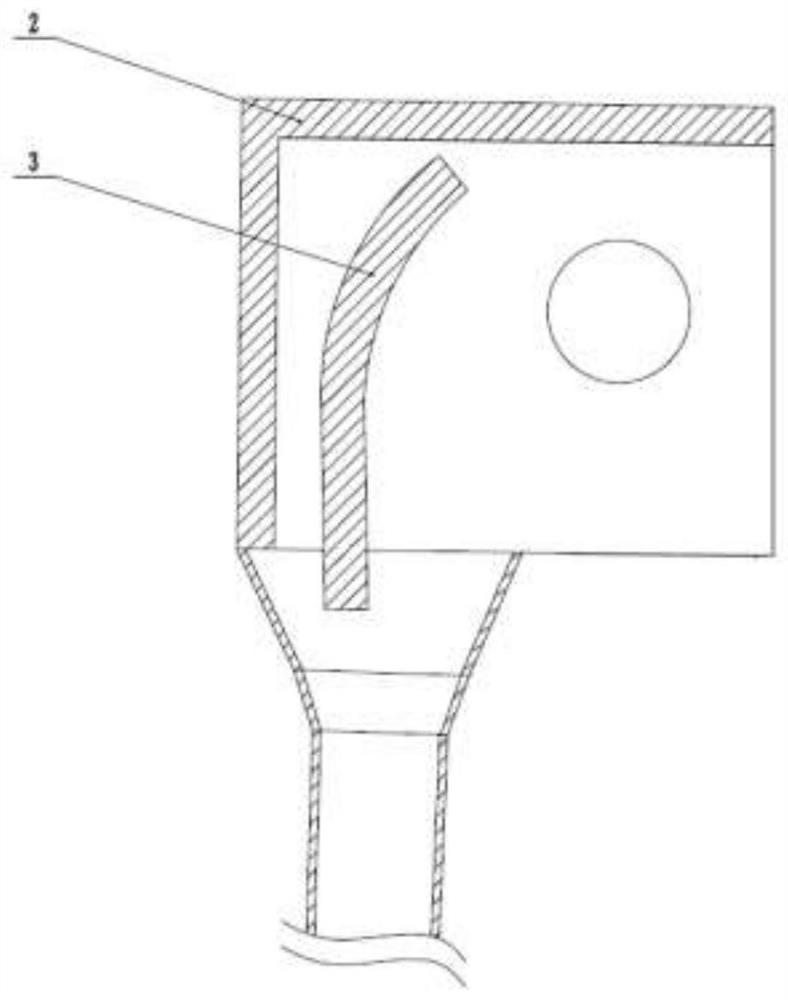

[0023] A smart multi-phase flow self-circulation energy-saving dust suppression and dust removal device, such as Figure 1-4 As shown, the upper conveyor belt 1 is included, and the upper conveyor belt 1 is fixedly connected with the separated upper shroud 2, and the material is diverted in the separated shroud to be transported downward. The separated shroud 2 is equipped with a passage The detachable arc-shaped deflector 3 connected by the shaft pin, that is, adding a replaceable arc-shaped deflector, which facilitates the replacement of wearable parts, increases the service life of the entire transfer system, reduces equipment maintenance costs, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com