Soluble granule containing active ingredient dinotefuran and preparation method of soluble granule

A dinotefuran and soluble technology, which is applied in the field of application and preparation of the agricultural insecticide dinotefuran soluble granules, can solve the problems of large dust and environmental pollution, achieve good drug efficacy, high suspension rate, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

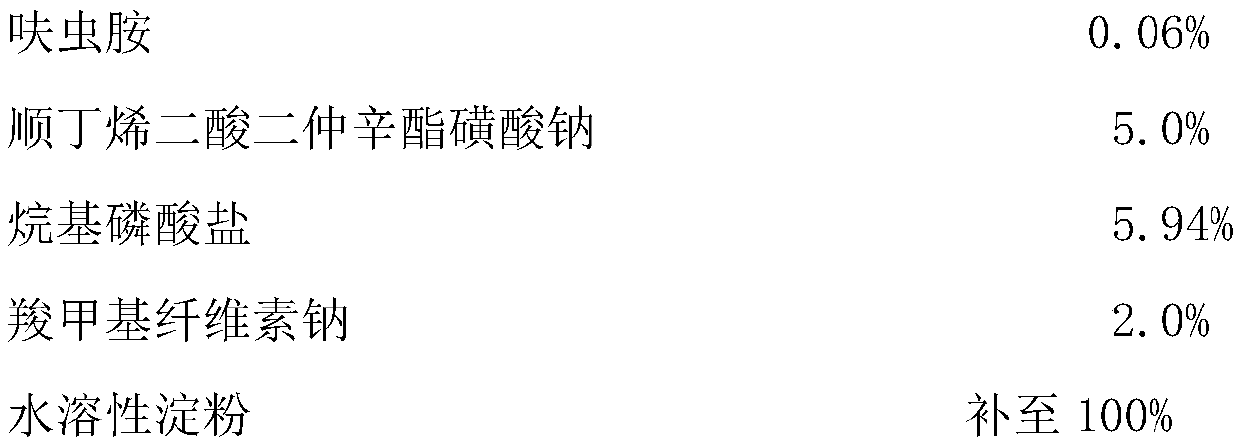

[0026] Example 1 0.06% dinotefuran soluble granules

[0027]

[0028] Put the water-soluble starch into the intermediate silo, pulverize it through an ultra-fine pulverizer, add the pulverized material to the binder sodium carboxymethyl cellulose for granulation, and obtain the base nucleus; dinotefuran, dispersant and Di-sec-octyl sodium butenedioate and alkyl phosphate as a wetting agent are evenly mixed, and then sprayed on the surface of the base core to obtain a soluble granule containing the active component dinotefuran.

Embodiment 2

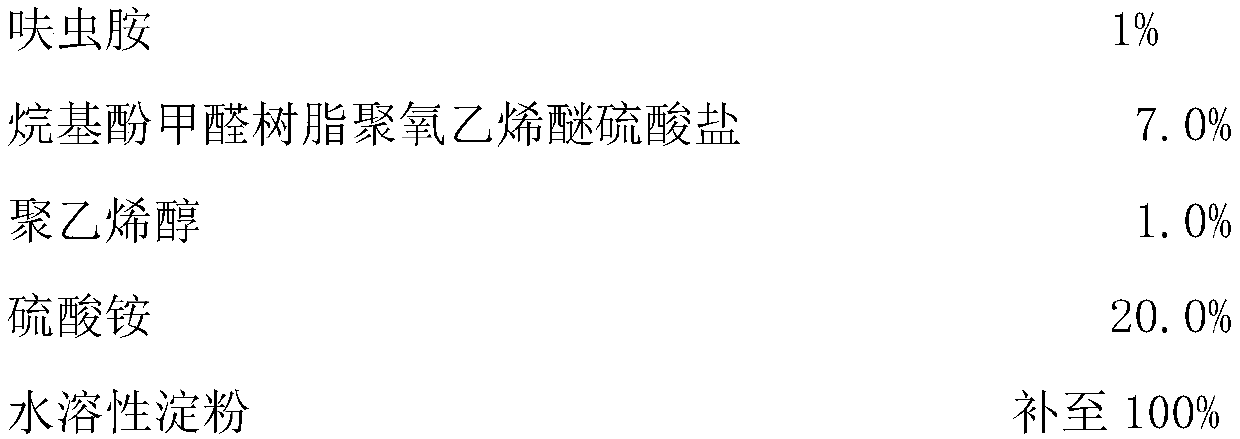

[0029] Example 2 1% dinotefuran soluble granules

[0030]

[0031] Add ammonium sulfate, water-soluble starch and alkylphenol formaldehyde resin polyoxyethylene ether sulfate into the mixer after metering, start stirring, and after mixing evenly, put it into the intermediate silo and grind it through an ultrafine grinder. Good materials are added with polyvinyl alcohol as a binder for granulation, and then dried to obtain soluble granules containing dinotefuran as an active component.

Embodiment 3

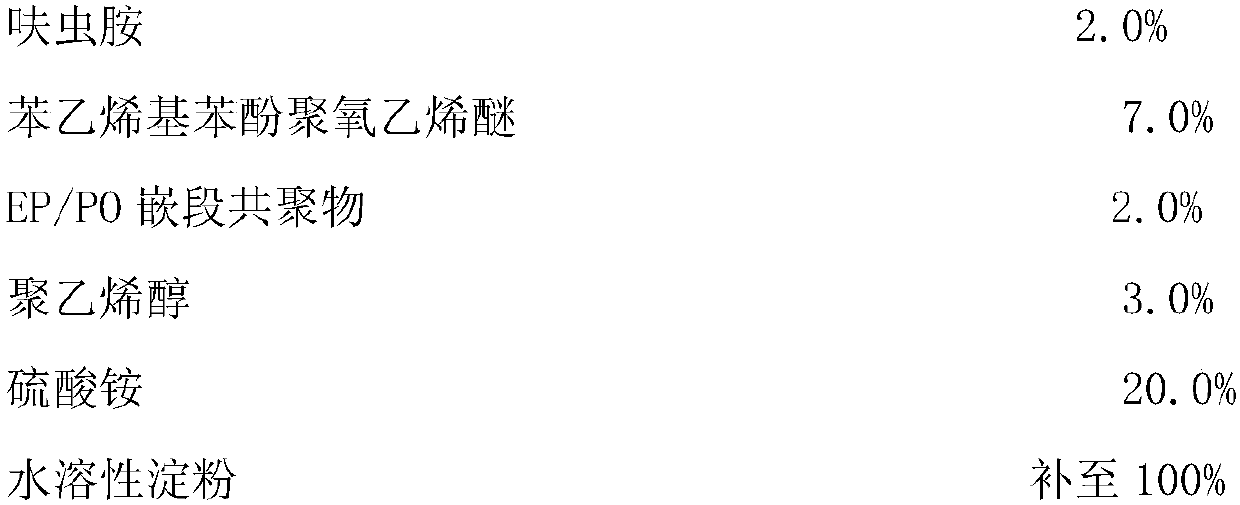

[0032] Example 3 2% dinotefuran soluble granules

[0033]

[0034] Put the water-soluble starch and ammonium sulfate as the carrier into the intermediate silo, pulverize through the ultra-fine pulverizer, add the pulverized material to the binder polyvinyl alcohol for granulation, and obtain the base nucleus; polystyrene phenol After the oxyethylene ether, EP / PO block copolymer and dinotefuran are mixed evenly, they are sprayed and coated on the surface of the base core to obtain soluble granules containing the active component dinotefuran.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com