Method for manufacturing low-lead granular zinc citrate

A zinc citrate, granular technology, which is applied in the granulation of special binders, pharmaceutical formulations, carboxylate preparations, etc., can solve the problems of non-viscosity and the formation of tiny powder particles, etc., to solve the problem of dust and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

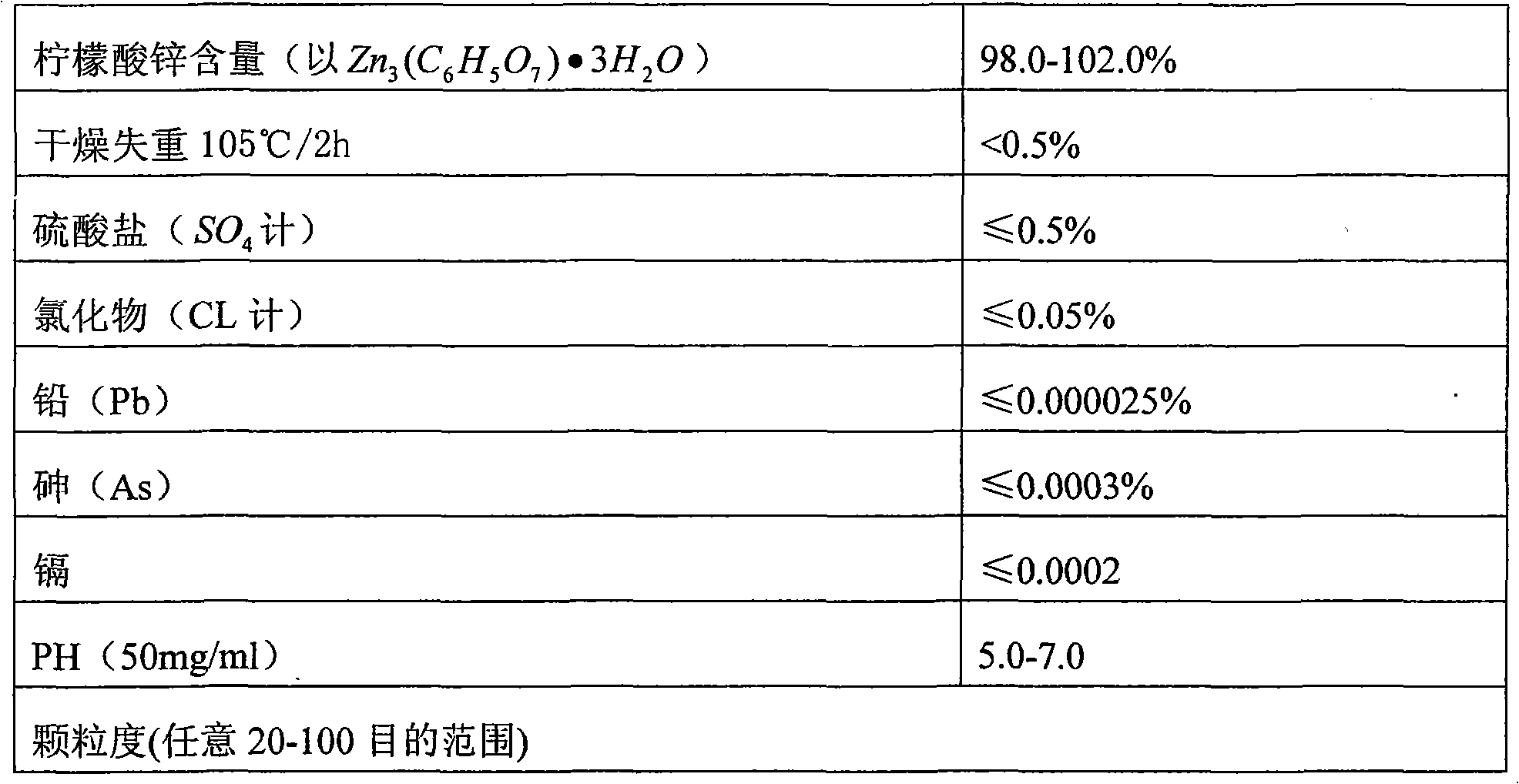

Image

Examples

Embodiment

[0021] 1. produce zinc sulfate solution, filter and remove impurity, promptly by following weight ratio: zinc sulfate (by not containing crystal water): water=1: 3 makes zinc sulfate solution after fully reacting, filters, clarifies.

[0022] 2 react the prepared zinc sulfate solution (the content of zinc sulfate accounts for about 20%) with sodium bicarbonate, dissolve the sodium bicarbonate before the reaction, and then carry out metathesis according to the following weight ratio, zinc sulfate: sodium bicarbonate=1: 0.52) , the obtained zinc carbonate was dehydrated, washed, dried, cooled, and sub-sieved to obtain material A.

[0023] 3. The above-mentioned material A, edible citric acid and water are according to the following weight ratio, material A: edible citric acid: water=1: 0.86: 4, are prepared into a solution and carry out chemical reaction, the reaction temperature is controlled between 70~100 ℃, the reaction The pH value of the solution is ≥7.

[0024] 4 Control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com