A device and method for eliminating residual stress of workpiece by using pulsed electromagnetic force

A residual stress and pulsed electromagnetic technology, applied in the field of metal manufacturing, can solve the problems of difficult precise control, small action range, low efficiency, etc., and achieve the effects of reducing residual stress, uniform force, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

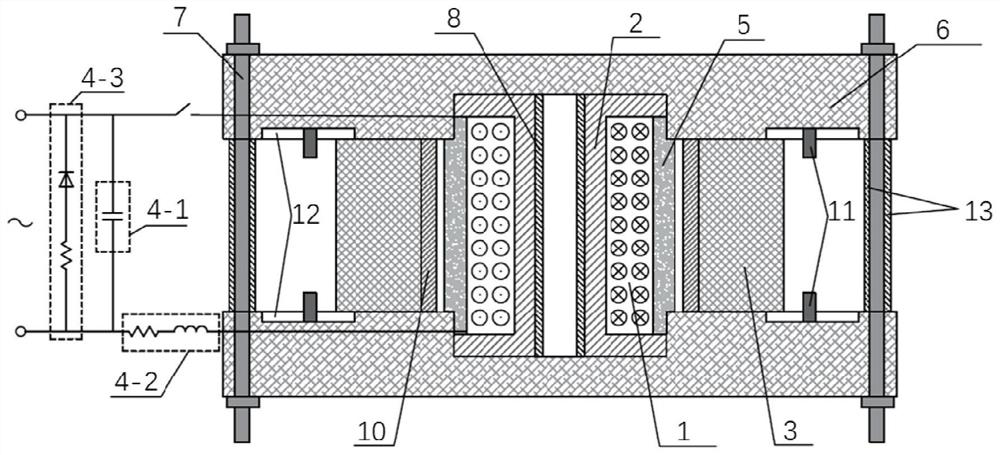

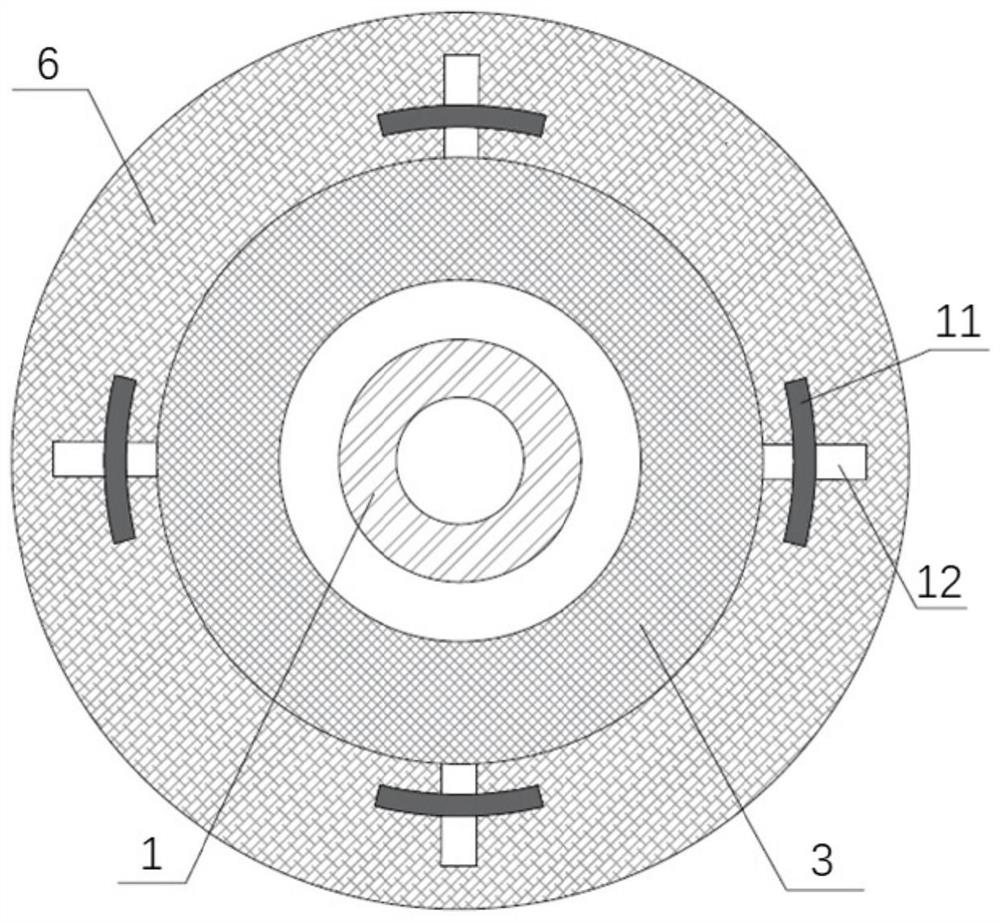

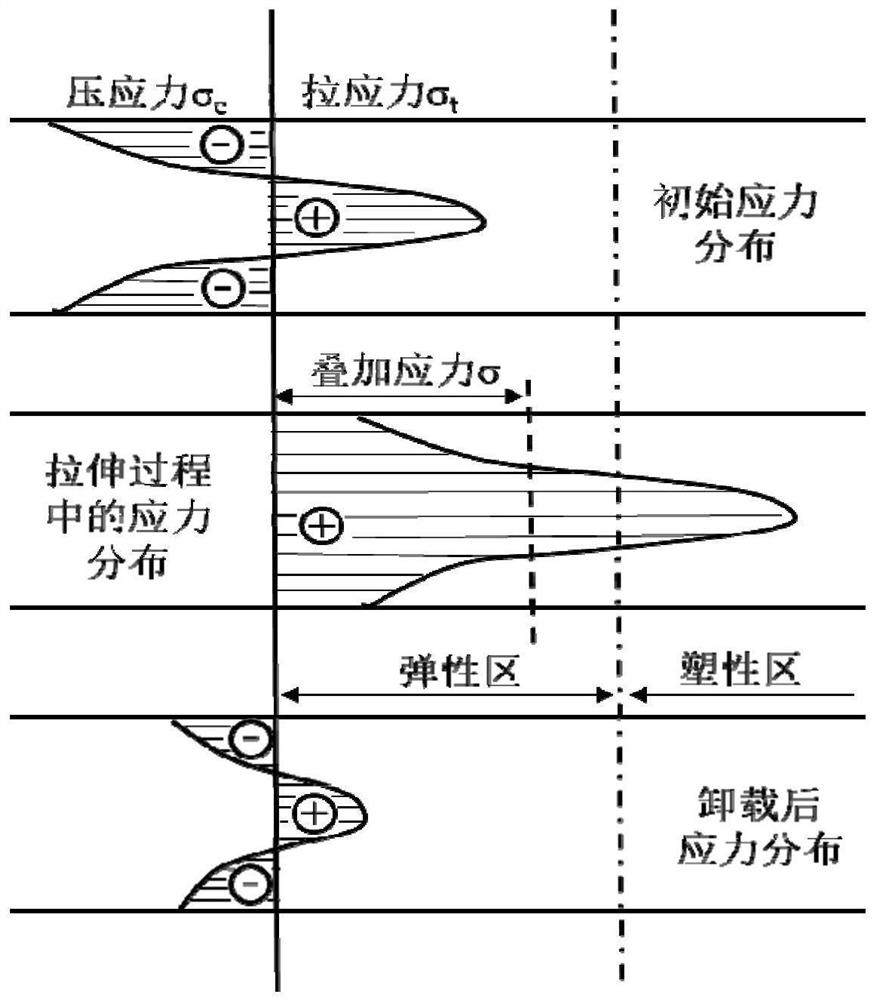

[0059] figure 1 The first embodiment of the device for eliminating the residual stress of the workpiece provided by the present invention, figure 2 It is a top view of this embodiment. The device includes: bulging coil 1, coil bobbin 2, support frame 8, pulse power supply system, magnetic collector 5, upper and lower end plates 6, fixed screw 7, support frame 8, driving workpiece 10, limit ring 11, sliding groove 12 , Steel support sleeve 13.

[0060] The metal workpiece 3 to be processed is wrapped around the bulging coil 1, and is discharged to the bulging coil through the pulse power supply system, and a large pulse current is passed through the coil, and a pulsed strong magnetic field is generated in the surrounding space, and then a pulsed strong magnetic field is induced in the metal workpiece to be processed. Eddy current, the interaction between eddy current and the strong magnetic field in space will generate a strong outward repulsive force, and the magnetic colle...

no. 2 example

[0068] Image 6 It is the second embodiment of the device for eliminating residual stress of the workpiece provided by the present invention. The device includes: a bulging coil 1 , a coil bobbin 2 , and a magnetic collector 5 .

[0069] The pulse power supply discharges to the bulging coil 1, and a large pulse current is passed through the coil, and a pulse strong magnetic field is generated in the surrounding space, thereby inducing eddy currents in the metal workpiece to be processed. The difference from the first embodiment is that the metal workpiece in this embodiment has an irregular shape. Therefore, the shape of the outer surface of the magnetic collector 5 is designed to be consistent with the shape of the inner surface of the metal workpiece, because the magnetic collector can make the magnetic field line along it. The surface distribution of the coil can make the magnetic field generated by the coil evenly distributed in the metal workpiece, and the interaction bet...

no. 3 example

[0073] Figure 7 It is a third embodiment of the device for eliminating residual stress of a workpiece provided by the present invention. The device includes: a bulging coil 1 , a coil bobbin 2 , and a telescopic rod 9 .

[0074] The device is suitable for processing large metal workpieces. Using a distributed coil structure, multiple coils 1 are arranged inside the metal workpiece 3 to be processed, and each coil is discharged through a pulse power supply to generate a pulsed strong magnetic field in space. , and then induce eddy currents in the metal workpiece to be processed, and the interaction with the magnetic field will generate a strong Lorentz force, which superimposes with its original residual stress to generate plastic strain and release the residual stress.

[0075] Due to the method of arranging the array coils, the production cost and use risk of a single large coil are reduced, and the strength requirements and volume of each coil are greatly reduced. Ability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com