High-conductivity copper alloy containing tellurium and nickel and preparation method thereof

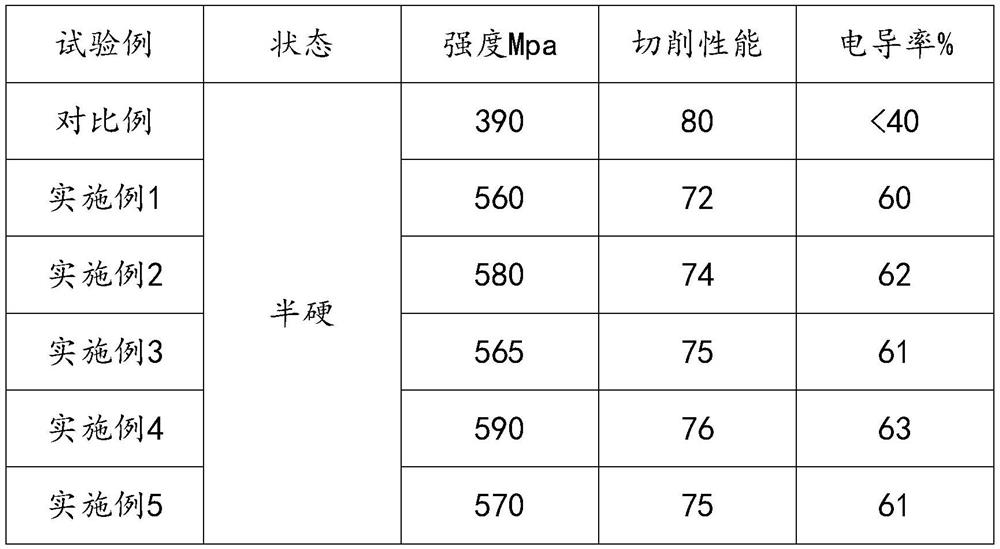

A copper alloy and high-conductivity technology, applied in the field of high-conductivity copper alloy and its preparation, can solve the problems of high alloy strength and low plasticity, and achieve the effects of high purity, high raw material stability and good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of a high-conductivity copper alloy containing tellurium-nickel, comprising the following steps:

[0044] S1. According to the composition of the raw materials, each component is weighed according to the weight percentage, and set aside;

[0045] S2. Preheat the melting furnace, add the weighed pure copper into the melting furnace and cover the graphite flakes, heat up and melt to a liquid state;

[0046] S3, after the pure copper is completely melted, add metal nickel to the copper liquid, and continue to stir slowly;

[0047] S4, after the metal nickel is completely melted, add phosphor-copper alloy and high-purity iron successively, and continue to stir slowly, the phosphorus in the phosphor-copper alloy accounts for 0.4% of the copper liquid weight;

[0048] S5. After slowly raising the temperature to completely melt the high-purity iron, add the pure hoof and continue to stir slowly. After the pure hoof is completely melted, the copper alloy liq...

Embodiment 2

[0062] A preparation method of a high-conductivity copper alloy containing tellurium-nickel, comprising the following steps:

[0063] Weigh 97% of copper, 0.7% of tellurium, 2% of nickel and 0.29% of iron in percentage by weight, and place them for later use; preheat the melting furnace to 500°C, add the weighed pure copper into the melting furnace and add it to its weight The 1% graphite flakes cover the copper layer evenly, and the temperature is raised to 1100°C at a heating rate of 50°C / min. After the pure copper is completely melted into copper liquid, add the weighed metallic nickel to the copper liquid, and continue to stir slowly for 2 minutes. Finally, stop stirring until the metal nickel is completely melted, add elemental phosphorus accounting for 0.1% of the weight of the copper liquid, and then add high-purity iron for about 30 minutes, then continue to stir slowly for 2 minutes; slowly raise the temperature to 1100 ° C, and wait until the high-purity iron is compl...

Embodiment 3

[0065] Different from Example 1, the content of each component in this example is calculated by weight percentage: copper 97.98%; tellurium 0.5%; nickel 1%; iron 0.5%; unavoidable impurities 0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap