A twisting device of a parallel twisting machine

A technology of twisting device and doubling machine, which is applied in textile and papermaking, fiber processing, fiber opening and cleaning, etc., can solve problems such as affecting the quality of the thread body, burrs on the side of the thread body, and yarn tightening due to heat, and achieves adjustment and adaptation. Good performance, reduced failure rate, reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

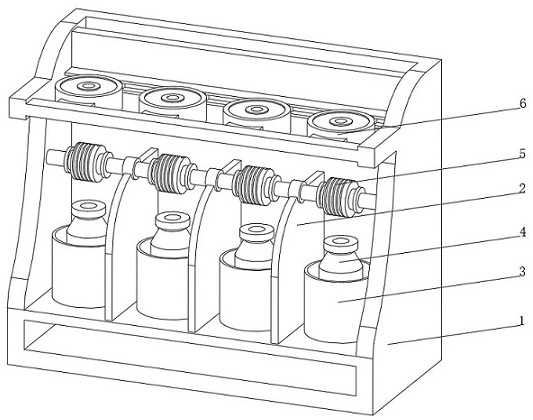

[0037] see Figure 1-3 , the present invention provides a technical solution: a twisting device of a twisting machine, specifically comprising:

[0038]A frame 1, the bottom of the inner wall of the frame 1 is fixedly connected with a partition 2, and the part of the bottom of the inner wall of the frame 1 located on one side of the partition 2 is fixedly connected with a retaining ring 3;

[0039] Yarn storage drum 4, the yarn storage drum 4 is arranged inside the retaining ring 3, and the yarn storage drum 4 is rotationally connected with the bottom of the inner wall of the frame 1 through a rotating shaft;

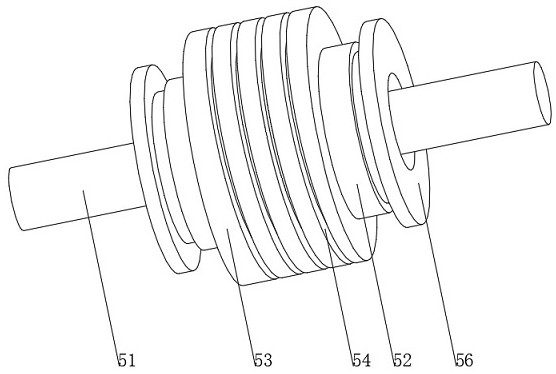

[0040] A heating device 5, the heating device 5 is arranged above the yarn storage drum 4, and both ends of the heating device 5 are fixedly connected to the inner wall of the frame 1;

[0041] A cleaning device 6, the cleaning device 6 is arranged above the heating device 5, and both ends of the cleaning device 6 are fixedly connected to the inner wall of the frame 1;...

Embodiment 2

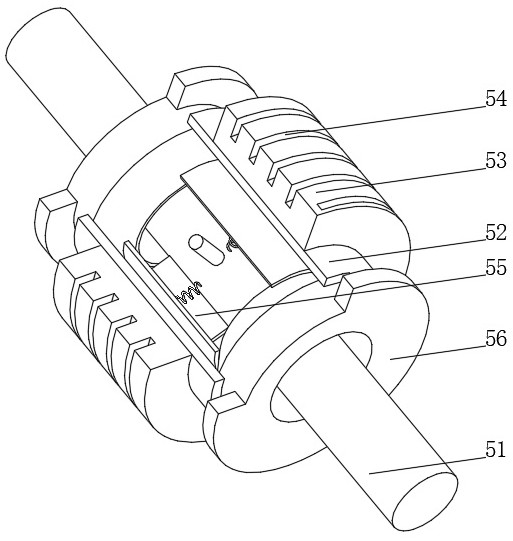

[0049] see Figure 1-6 The present invention provides a technical solution: the cleaning device 6 includes a fixed frame 61, and both sides of the inner wall of the fixed frame 61 are provided with chute 62, the inner wall of the chute 62 is slidably connected with a bracket 63, and the inner side of the bracket 63 is fixedly connected with a rotating disk 64, The inside of the rotating disk 64 is fixedly connected with an electronic rotating seat 65, and the top of the electronic rotating seat 65 is fixedly connected with a cleaning disk 66. The center of the cleaning disk 66 is provided with a cleaning hole 67, and the inner wall of the cleaning hole 67 is provided with a clamping groove 68, and the bottom of the internal wall of the clamping groove 68 A cleaning brush 69 is fixedly connected, and both ends of the fixed frame 61 are fixedly connected with the inner wall of the frame 1. The bracket 63 is provided with multiple groups and corresponds to the yarn storage tube 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com