Quick mounting joint for corrugated pipe and corrugated pipe applying quick mounting joint

A technology for installing joints and corrugated pipes, applied in the direction of pipes/pipe joints/fittings, hose connection devices, couplings, etc., to avoid misalignment, good sealing effect, and improve the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

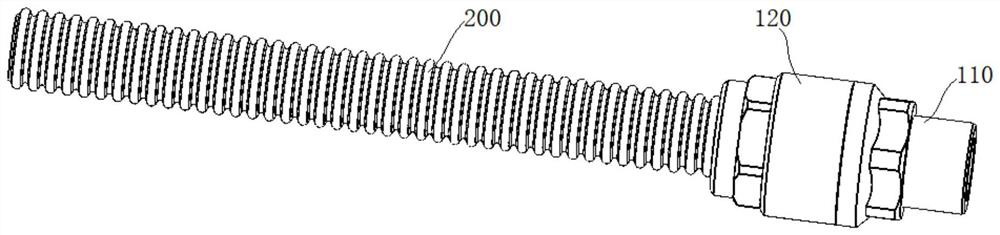

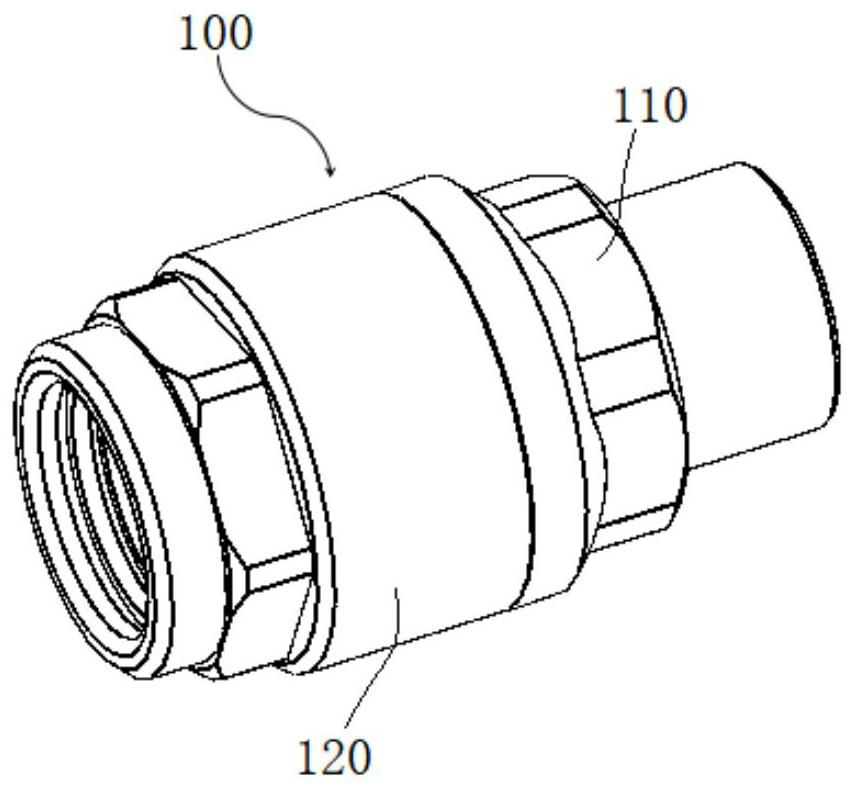

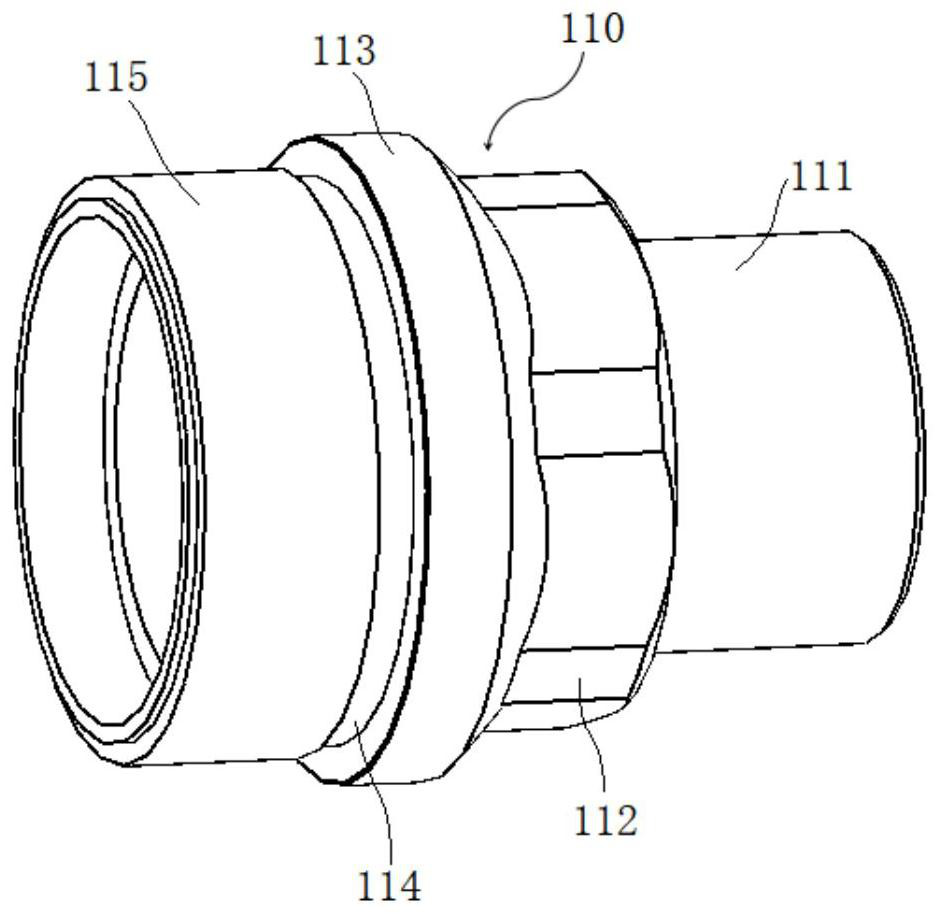

[0045] Combine Figure 1 - Figure 13 As shown, a bellows rapidly mount joint and the bellows applying the joint, including the mating base inner wire 120 and the outer wire joint 110, the base inner wire 120 and the outer wire 110 is the bellows 200 hard The form of structural forms in the sealing joint, which achieves hard seal by fitting tightening. like Figure 7 Design, the outer hollow retaining ring 130 is mounted inside the outer wire joint 110, and the retaining ring 130 includes an inner block 131 and the expansion segment 133, wherein the expansion segment 133 is mounted having a snap ring 140, the snap ring 140 includes a plurality of The ring ring body 141 and the elastic ring 143 of the arc structure, the outer circumference of the snap ring body 141 is opened, and the elastic ring 143 is embedded in the concave groove, and the elastic ring 143 will sequentially The ring structure is formed in series, and the elastic ring 143 has a certain elasticity, and when the snap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com