Building engineering quality flatness detection device

A technology for flatness detection and construction engineering, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of low detection efficiency, achieve high detection efficiency, strong practicability, and reduce frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7 The application is described in further detail.

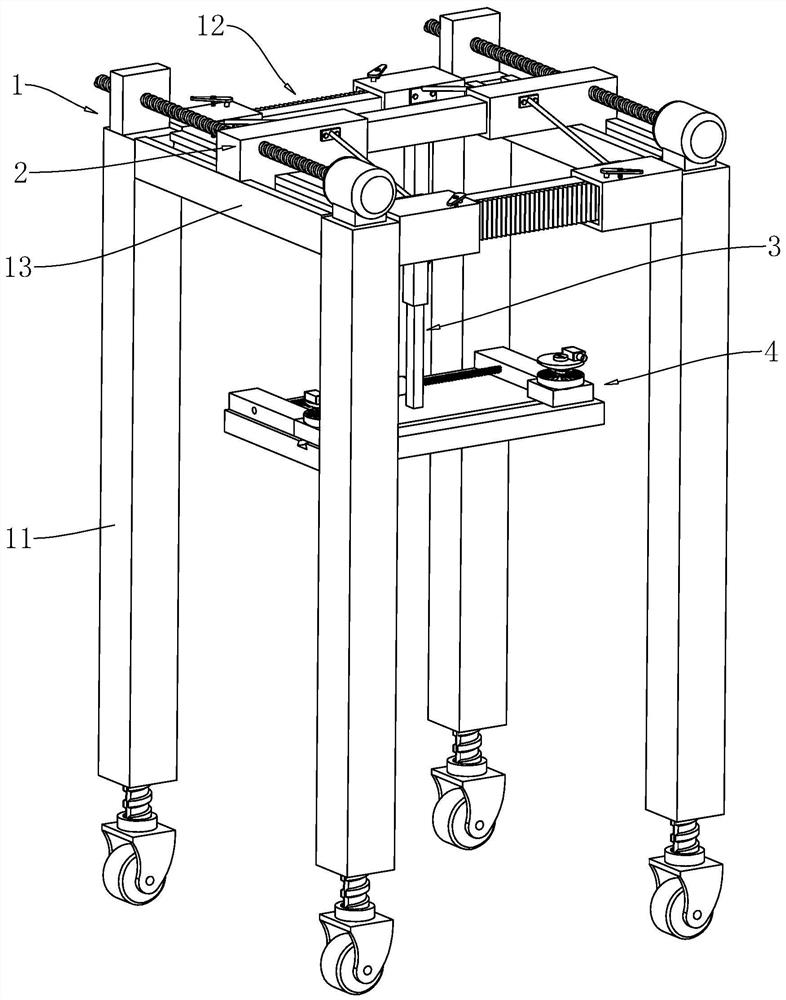

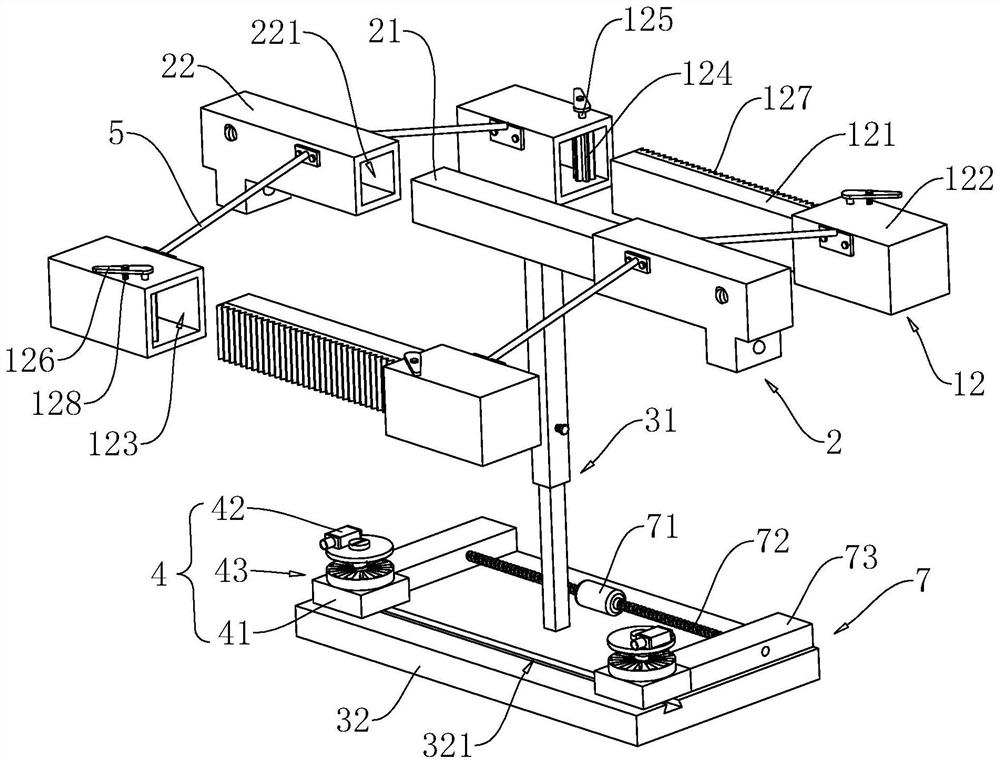

[0040] The embodiment of the present application discloses a construction project quality flatness detection device. refer to figure 1 The construction quality flatness detection device includes a frame 1, a crossbeam 2 slidably arranged on the frame 1, a mounting frame 3 connected to the crossbeam 2, and at least one set of detection components 4 slidingly disposed on the mounting frame 3. There are two sets of detection components 4 in the embodiment, and other numbers can also be set in other implementation manners.

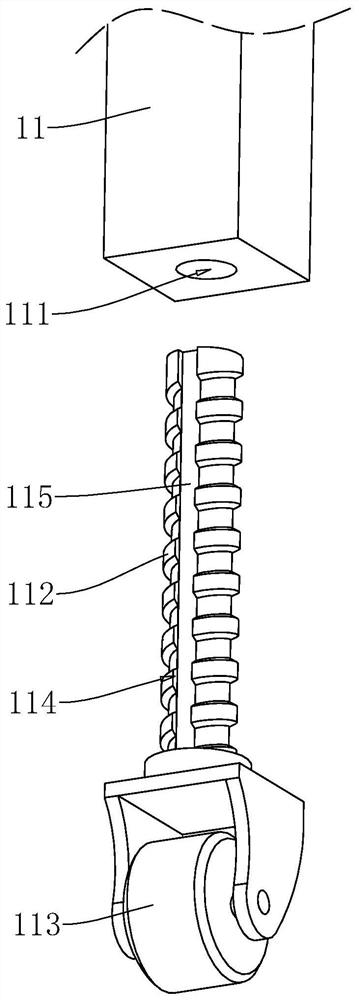

[0041] refer to figure 1 , the frame 1 includes four mutually parallel columns 11, two mutually parallel telescopic rods 12 and two mutually parallel positioning rods 13, the vertical columns 11 are arranged vertically, the telescopic rods 12 and the positioning rods 13 are arranged horizontally, And the positioning rod 13 is perpendicular to the telescopic rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com