Gas and water composite cooling visual probe structure

A composite cooling and water cooling technology, used in the field of visual probes, can solve the problems of high airflow velocity, cold and hot flow field interference, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

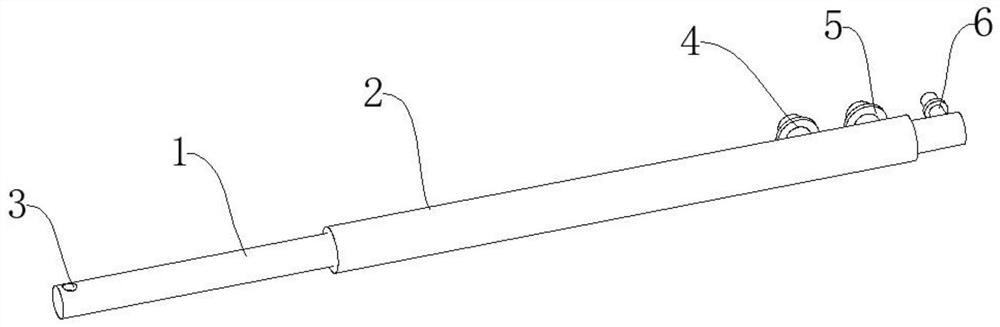

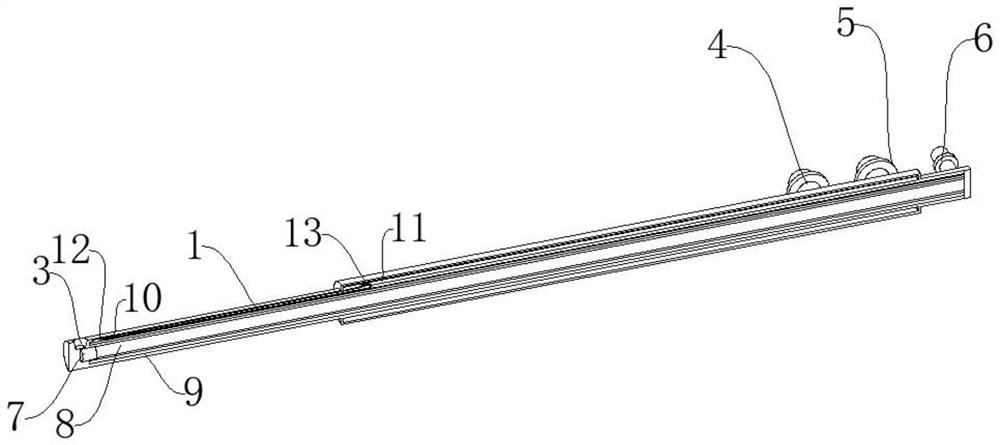

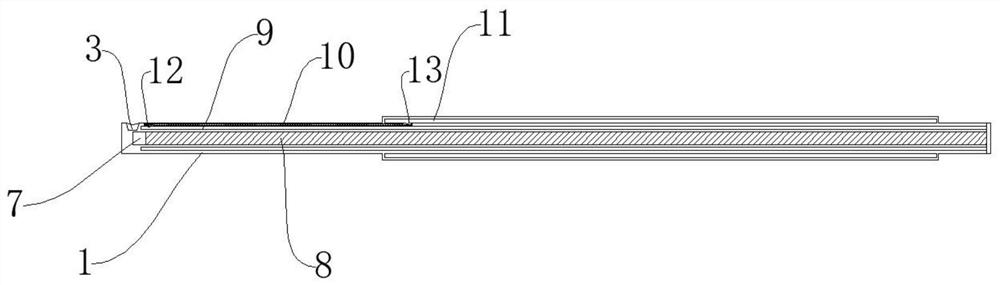

[0028] like Figure 1-Figure 3 As shown, a gas-water composite cooling visualization probe structure includes an inner protective cover 1 for providing air-cooled and water-cooled media and an outer protective cover 2 for displacing return water. The outer rear end of the inner protective cover 1 is provided with an outer protection Cover 2, the top of the inner protective cover 1 is provided with a first optical observation hole 3, the inside of the inner protective cover 1 and the central area of the probe are provided with an air-cooled circulation chamber 8, and the top of the air-cooled circulation chamber 8 is provided with a second optical observation 7, An air-cooling valve 6 is connected to one side of the tail of the air-cooling circulation chamber 8, and a water-cooling water inlet chamber 9 is arranged on the outside of the air-cooling circulation chamber 8 and inside the inner protective cover 1. A water-cooled return chamber 10 is provided inside, and a micro-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com