Adjustable optical fiber welding device with fixing and skin cutting functions

An optical fiber fusion splicing and adjustable technology, applied in the field of communication optical fiber fusion, can solve the problems of increased difficulty in fusion splicing work, cumbersome fusion splicing process, troublesome operation, etc., and achieve the effect of convenient overall use and operation, high efficiency and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

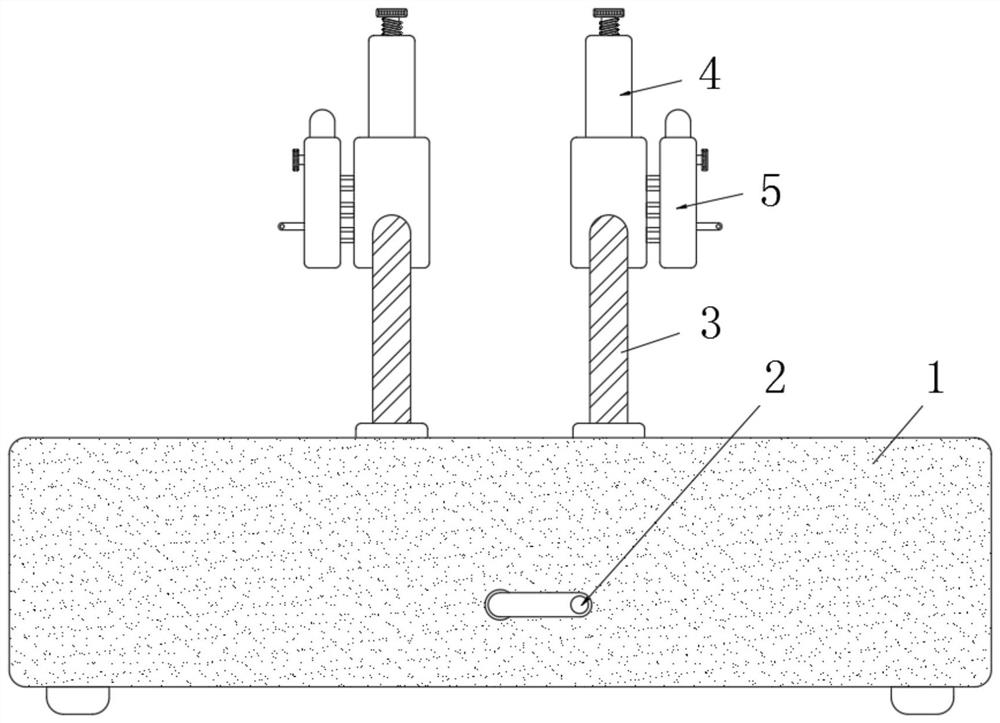

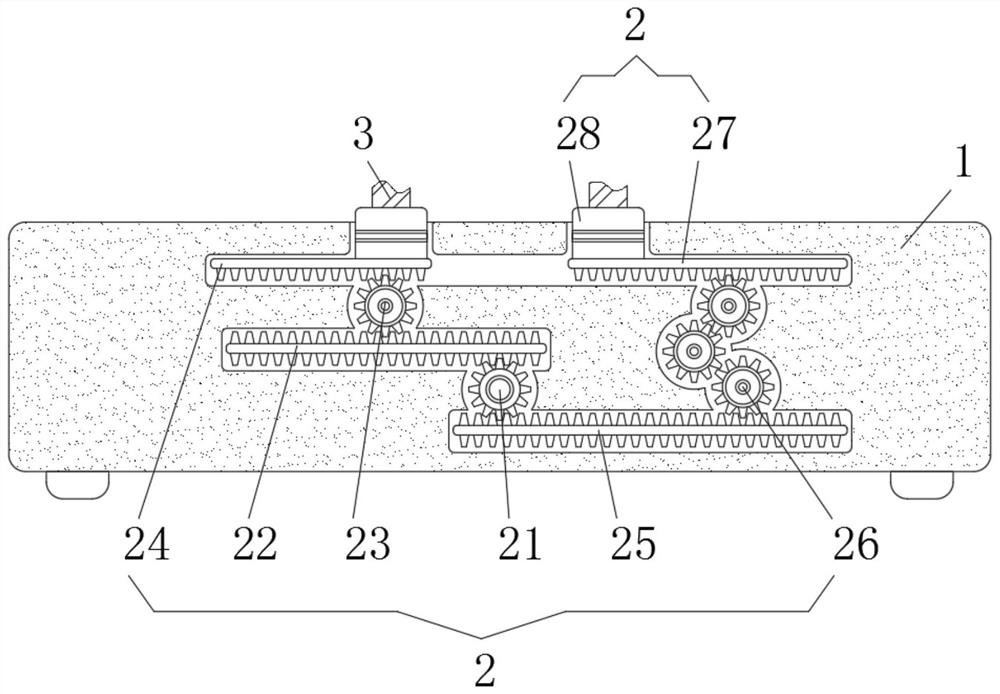

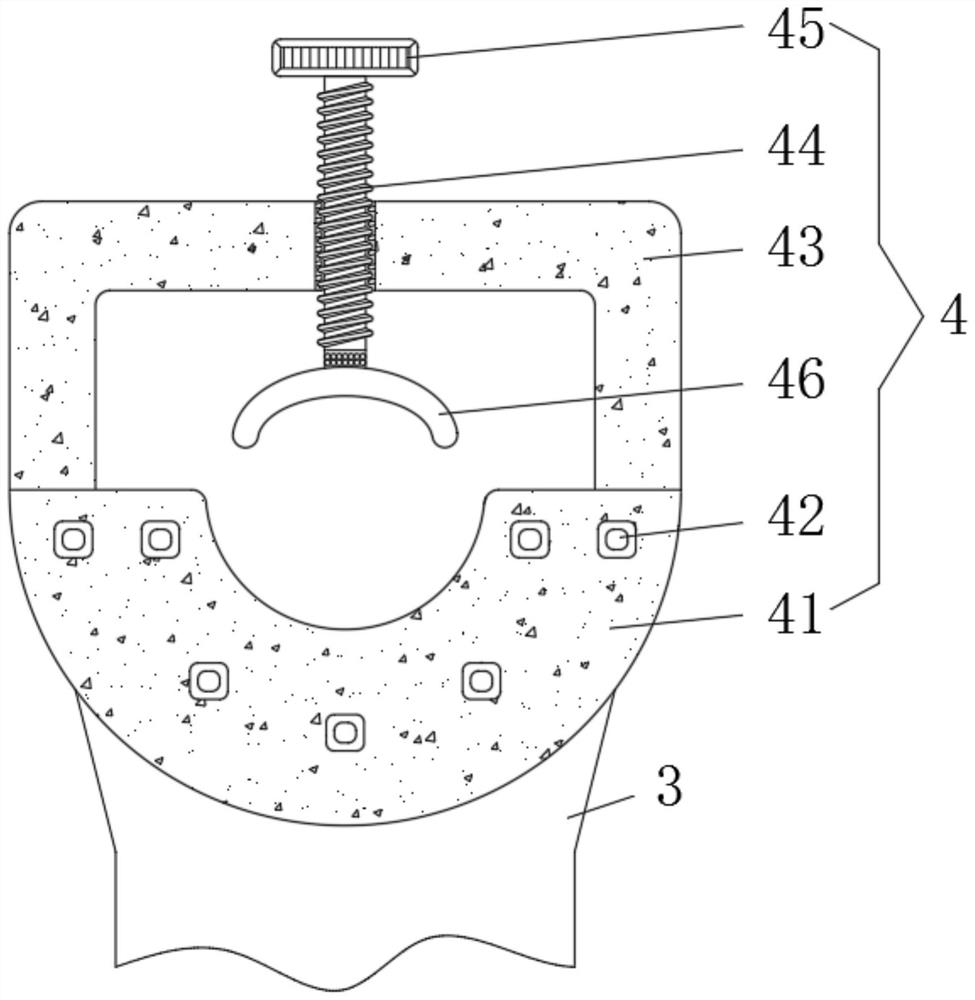

[0028] see Figure 1-3 , the inside of the base 1 is fixedly installed with a transmission mechanism 2, the top of the base 1 is fixedly installed with a mounting bracket 3, the top of the mounting bracket 3 is fixedly installed with a fixing mechanism 4, one end of the fixing mechanism 4 is fixedly connected with a skin cutting mechanism 5, and the transmission mechanism 2 includes gear one 21, tooth plate one 22, gear two 23, tooth plate two 24, tooth plate three 25, gear assembly 26, tooth plate four 27 and slide block 28, and the top of gear one 21 is meshed with tooth plate one 22 , gear two 23 is meshed above tooth plate one 22, tooth plate two 24 is meshed above gear two 23, tooth plate three 25 is meshed below gear one 21, and gear assembly 26 is meshed above the right end of tooth plate three 25 , the top of the gear assembly 26 is meshed with tooth plate four 27, the top of tooth plate two 24 and tooth plate four 27 is fixedly equipped with a slider 28, the surface o...

Embodiment 2

[0030] see figure 1 , 4, 5, 6, the inside of the base 1 is fixedly installed with a transmission mechanism 2, the top of the base 1 is fixedly installed with a mounting bracket 3, the top of the mounting bracket 3 is fixedly installed with a fixing mechanism 4, and one end of the fixing mechanism 4 is fixedly connected with a skin cutting mechanism 5. The epidermis cutting mechanism 5 includes a cutting main casing 51, a handle 52, a chute 53, a sliding installation block 54, a movable connecting rod 55, a cutting blade 56, a fixed tooth plate 57, a gear three 58 and a gear four 59, and the cutting main shell A handle 52 is fixedly installed on the surface of the body 51, a chute 53 is provided inside the cutting main housing 51, a sliding installation block 54 is slidably installed on the chute 53, and a movable connecting rod 55 is fixedly installed on one side of the sliding installation block 54, The surface of the sliding mounting block 54 is provided with a cutting blad...

Embodiment 3

[0032] see Figure 1-6 , the inside of the base 1 is fixedly installed with a transmission mechanism 2, the top of the base 1 is fixedly installed with a mounting bracket 3, the top of the mounting bracket 3 is fixedly installed with a fixing mechanism 4, one end of the fixing mechanism 4 is fixedly connected with a skin cutting mechanism 5, and the transmission mechanism 2 includes gear one 21, tooth plate one 22, gear two 23, tooth plate two 24, tooth plate three 25, gear assembly 26, tooth plate four 27 and slide block 28, and the top of gear one 21 is meshed with tooth plate one 22 , gear two 23 is meshed above tooth plate one 22, tooth plate two 24 is meshed above gear two 23, tooth plate three 25 is meshed below gear one 21, and gear assembly 26 is meshed above the right end of tooth plate three 25 , the top of the gear assembly 26 is meshed with tooth plate four 27, the top of tooth plate two 24 and tooth plate four 27 is fixedly equipped with a slider 28, the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com