Wafer cleaning method and manufacturing method of semiconductor device

A technology of wafer and cleaning fluid, which is applied in semiconductor/solid-state device manufacturing, cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as device damage failure, device characteristic attenuation, reliability failure, etc., to achieve static electricity suppression, The effect of reducing device failure and improving overall yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

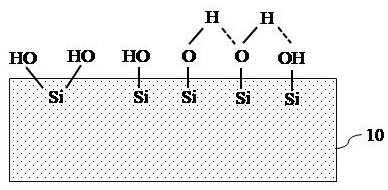

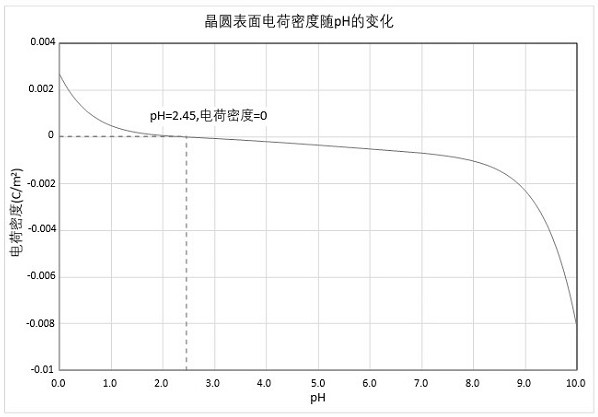

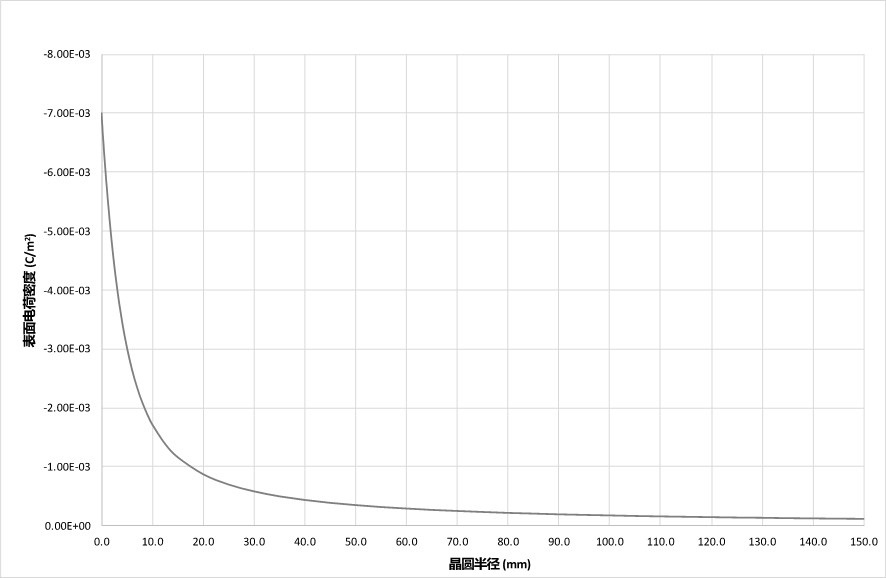

[0053] Since the silicon on the surface of the wafer is very easily oxidized, the surface of the wafer will be covered with a thin layer of silicon dioxide film during the processing of semiconductor devices. When the wafer surface comes into contact with the cleaning solution, the wafer surface becomes charged with a certain amount based on the dissociation / association constant of silica. In cleaning solutions with different electrolyte concentrations and different pHs, the charge amount on the wafer surface is different, and even a point of zero charge (PZC) will appear. The charge generated on the surface of the wafer will not only absorb charged pollutants, but also load the device. In severe cases, it will break down the device like electrostatic discharge, and eventually lead to the scrapping of the product. The mechanism of charge generation on the wafer surface is described below:

[0054] First, see figure 1 , in the process of cleaning the surface of the wafer 10 w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap