Automatic disinfection type storage device for optical lenses

An automatic disinfection and optical lens technology, applied in the field of optical lenses, can solve problems affecting the health of customers and infection of customers with infectious diseases, and achieve better sterilization and antivirus effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

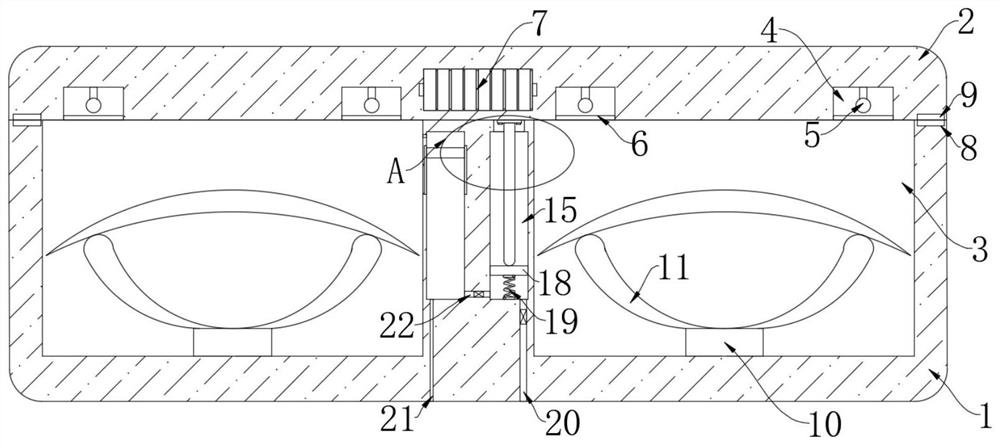

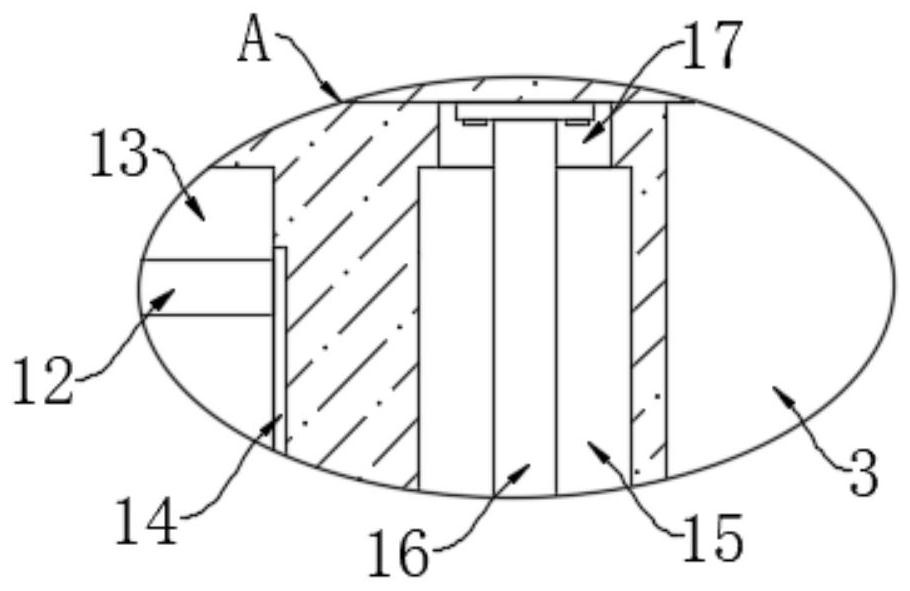

[0024] refer to Figure 1-2 , an automatic disinfection type storage device for optical lenses, comprising a housing 1, a cover plate 2 is arranged on the top of the housing 1, the weight of the cover plate 2 is relatively large, and two placement grooves 3 are arranged symmetrically on the upper end of the housing 1, The housing 1 is provided with 13 vertical cavities 15, the conductive cavity 13 and the vertical cavity 15 are located between the two placement grooves 3, the conductive cavity 13 is located on the left side of the vertical cavity 15, and the lower end of the cover plate 2 is provided with multiple A rectangular slot 4, a power supply 7 is arranged in the cover plate 2, and the power supply 7 is composed of a plurality of electronics;

[0025] The two placement slots 3 are jointly provided with a placement mechanism, the placement mechanism includes two square blocks 10 respectively arranged at the bottom of the two placement slots 3, and the upper ends of the ...

Embodiment 2

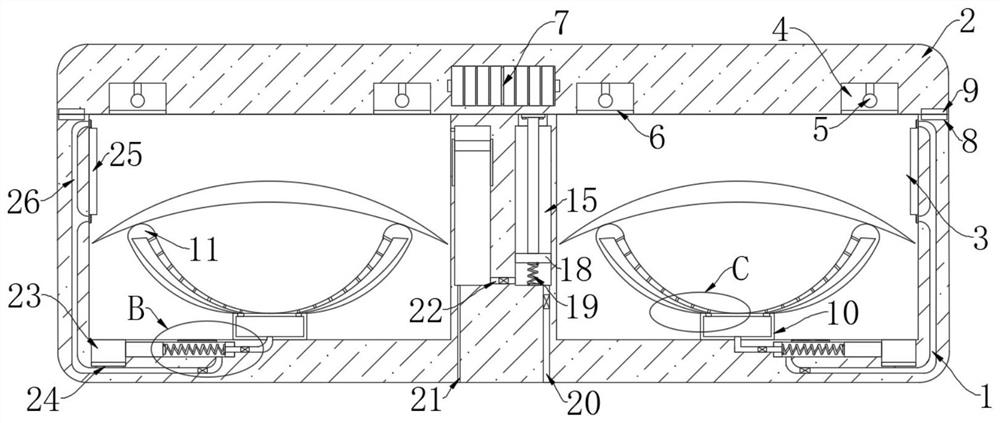

[0040] refer to Figure 3-5 The difference between this embodiment and Embodiment 1 is that the inner bottoms of the two placement grooves 3 are provided with light-shielding grooves 23, and the inner bottoms of the light-shielding grooves 23 are provided with photoresistors 24. When the photoresistors 24 are illuminated, the The resistance value is at the minimum value. When the photoresistor 24 is not exposed to light, the resistance value is at the maximum value. The adjacent sides of the two light-shielding grooves 23 are provided with chute 27, and both chute 27 are provided with The shading block 30, the shading block 30 is made of opaque material, the two shading blocks 30 are magnetic, the two shading blocks 30 are slidingly connected with the inner walls of the corresponding chute 27, and the two chute 27 is away from the corresponding shading One side inwall of groove 23 is all equipped with electromagnet 36, and power supply 7, the conductive sheet 14 that is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com