Reinforced scrubbing system for vertical flat-plate ceramic membrane and application of reinforced scrubbing system

A technology of ceramic membrane and ceramic membrane, which is applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of clogged ceramic membrane and limited effect of membrane pollution control, and achieve guaranteed retention, enhanced scrubbing effect, High technical and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

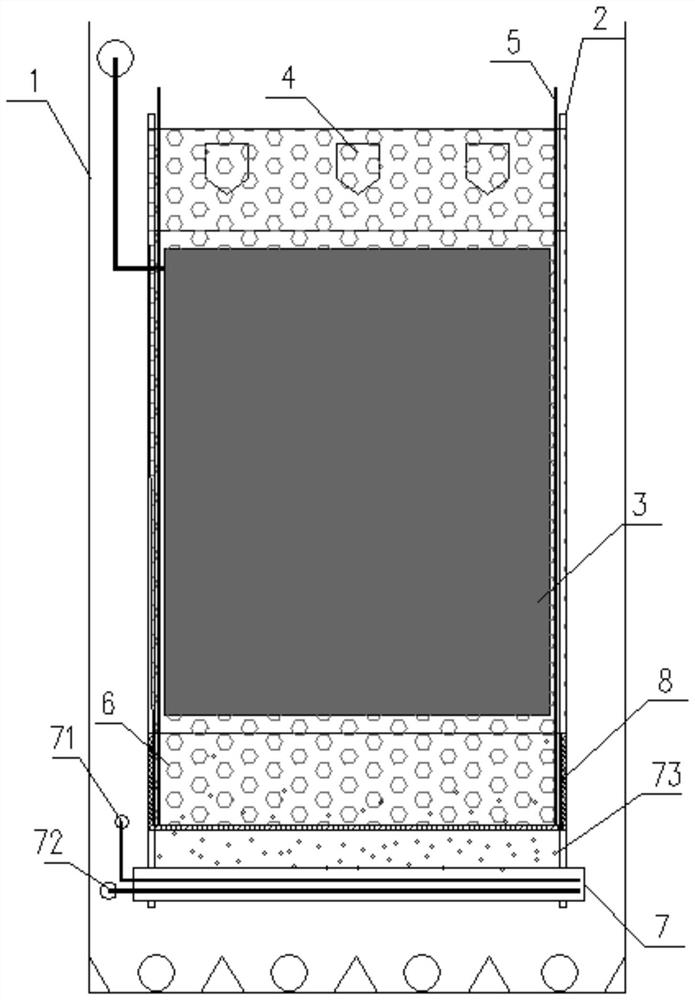

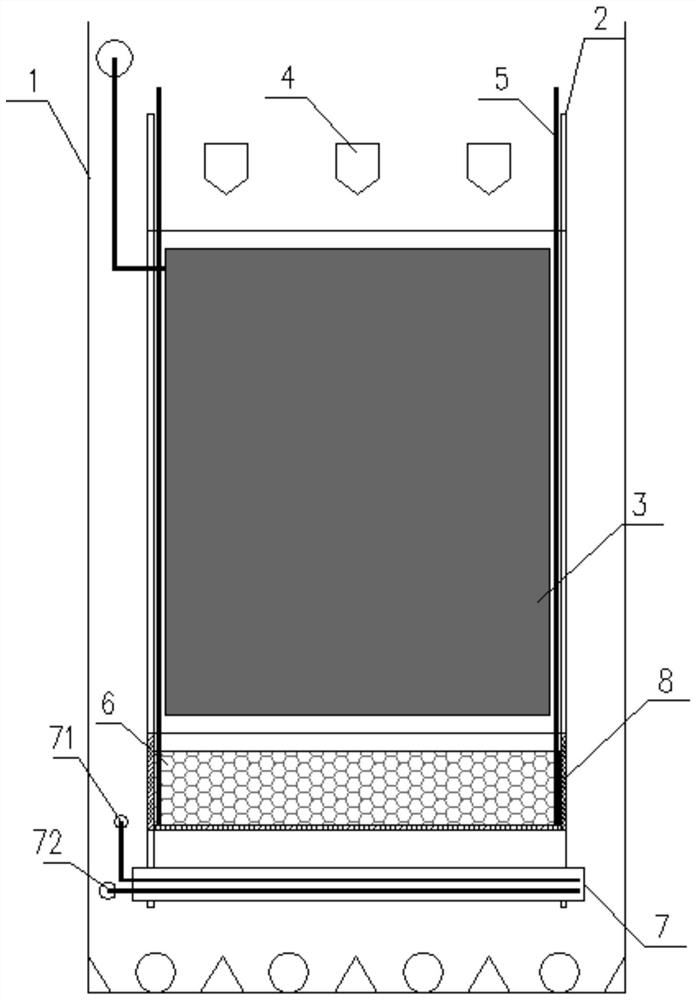

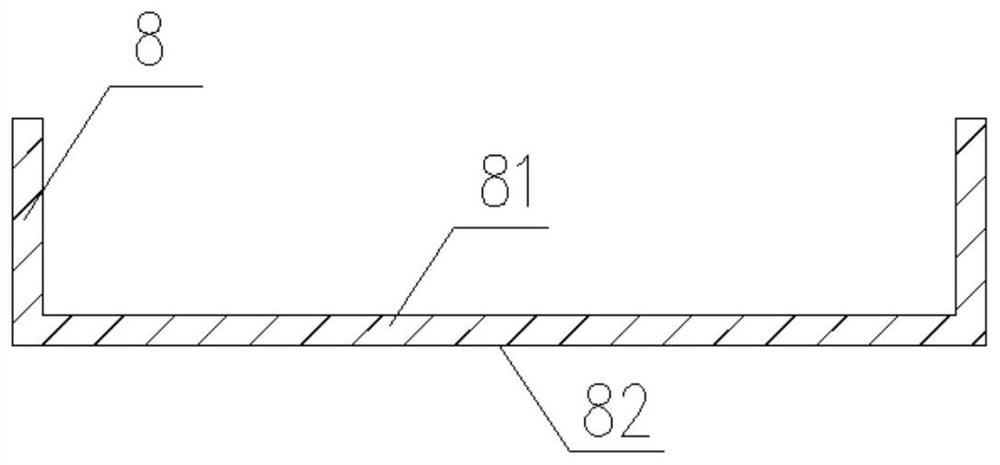

[0035] The present embodiment adopts the strengthened scrubbing system of vertically erecting the membrane frame. The scrubbing system includes: membrane pool 1, membrane frame 2, flat ceramic diaphragm 3, slag discharge tank 4, baffle plate 5, scrubbing particles 6, water distribution and air distribution box 7, particle tray 8; the membrane frames 2 are vertically arranged in parallel, Set water and air distribution box 7, scrubbing particles 6 and particle tray 8 from bottom to top, flat ceramic diaphragm 3 and slag discharge tank 4 arranged in parallel, the entire membrane frame 2 is immersed in membrane pool 1; flat ceramic diaphragm 3 is vertical Stand vertically with baffles 5 around; the scrubbing particles 6 can roll between the flat ceramic diaphragms 3 during air flushing. The standby schematic diagram of the enhanced scrubbing system with vertical membrane racks used in this embodiment is shown in figure 2 , the schematic diagram of air blast operation is shown i...

Embodiment 2

[0042] This embodiment adopts the enhanced scrubbing system of the vertical horizontal (double-layer) membrane frame, and the implementation mode is the same as that of Embodiment 1. The standby schematic diagram of the enhanced scrubbing system with vertical and horizontal (double-layer) membrane racks is shown in Figure 7 , the schematic diagram of air blast operation is shown in Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com