Online turbine mixer

A mixer and turbine technology, which is applied in mixers, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve the problems of difficult construction of pumping stations, difficulty in obtaining energy, and inability to adapt to changing working conditions, etc. Low cost and maintenance cost, simple and compact structure, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

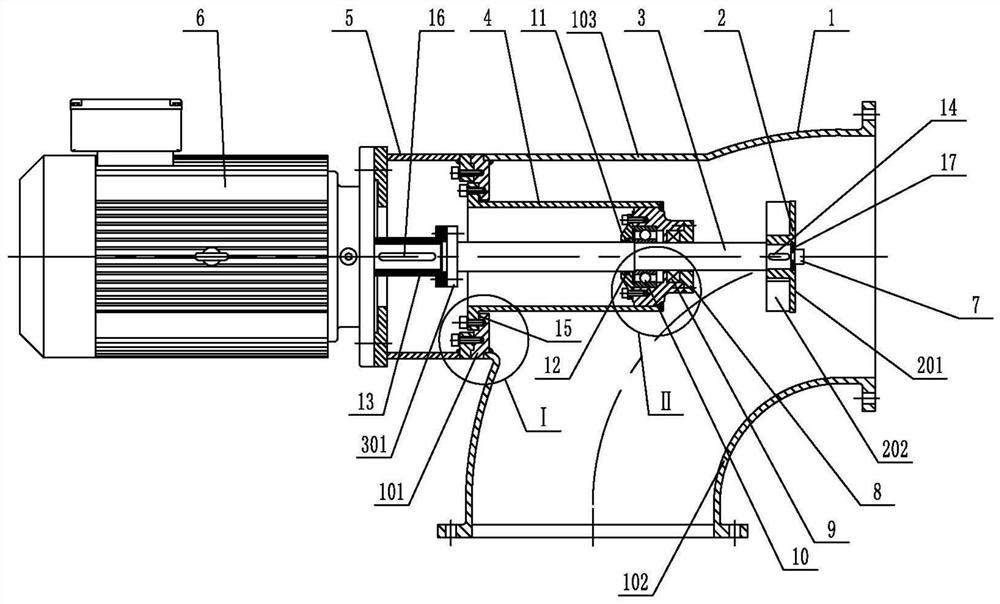

[0031] Such as figure 1 , Figure 4 , Figure 5 and Figure 6 As shown, this embodiment discloses an online turbine mixer, including a mixer housing 1, a stirring paddle wheel 2, a stirring shaft 3, a bearing seat 4, a motor bracket 5 and a motor 6, and the inside of the mixer housing 1 is provided with Stirring paddle wheel 2, stirring shaft 3 and bearing seat 4. The stirring paddle wheel 2 is fixed on one end of the stirring shaft 3 through the shaft head screw 7, the pressure ring 17 and the key 14, and the stirring shaft 3 is connected with the coupling 13 through the flange 301 arranged at the other end. The shaft coupling 13 is connected with the shaft extension of the motor 6 through the motor key, and transmits the power torque of the motor 6 to the shaft coupling 13 . The mixer housing 1 includes a 90° elbow 102 , an elbow seat 103 and a flange 101 . The elbow seat 103 is a tubular structure, which is arranged on the axis of a flange of the 90° elbow 102 , one en...

Embodiment 2

[0041] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the stirring paddle wheel 2 adopts a twist stirring paddle wheel, including 2 horizontal paddles 203 and 2 twist paddles 204, and the 2 horizontal paddles 203 are located on the same axis of rotation. In the plane, the two twist paddles 204 are symmetrical about the center of the rotation axis, the bone line of the two twist paddles 204 is a helical line, and the cross sections of the two horizontal paddles 203 and the two twist paddles 204 of the twist paddle wheel are rectangular.

[0042] The medium enters from the entrance of the lower end of the 90° elbow 102. When it reaches the vicinity of the twist paddle wheel, the horizontal paddle 203 mainly plays the role of stirring and mixing, and the twist paddle 204 plays the role of scraping and propulsion. First, it can prevent the high-viscosity medium from adhering at 90° Elbow 102 inner wall, the 2nd, can propel medium at low...

Embodiment 3

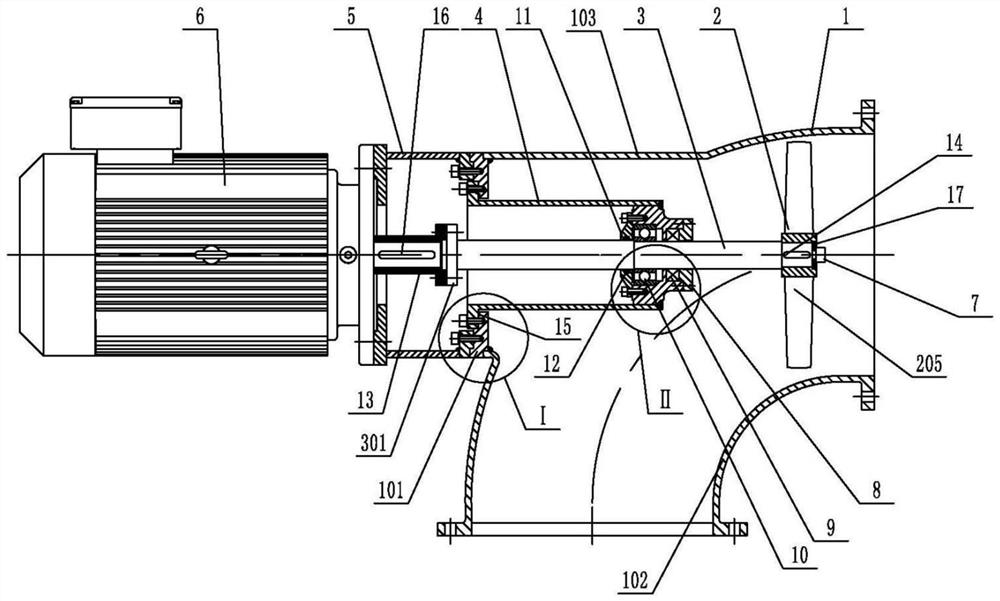

[0044] Such as image 3 As shown, the difference between this embodiment and the first embodiment and the second embodiment is that the stirring paddle wheel 2 adopts an axial flow propulsion type paddle wheel, including 2 to 3 axial flow blades 205, and the section of the axial flow blade 205 is a standard airfoil .

[0045] The medium enters from the inlet at the lower end of the 90° elbow 102, and when it reaches the vicinity of the axial-flow propulsion paddle wheel, the axial-flow propulsion paddle plays the role of mixing and propulsion, and finally the medium is discharged from the outlet at the right end of the 90° elbow 102 to the right. The axial-flow propulsion paddle wheel is suitable for low-viscosity media, and the speed is medium speed. The speed is determined by the power frequency of the motor and the number of poles of the motor.

[0046] Compared with the prior art, the in-line turbo mixer according to the present invention has significant advantages.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com