Tea stem-connected bud breaking device

A tea stalk and together technology, applied in the field of color sorter auxiliary setting, can solve the problems that the color sorter cannot accurately judge whether the stalks and buds are stalks or buds, the accuracy of color sorting is reduced, and tea waste is achieved, and the phenomenon of broken tea can be improved, The tea leaves are carefully sorted and the effect of speeding up the screening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

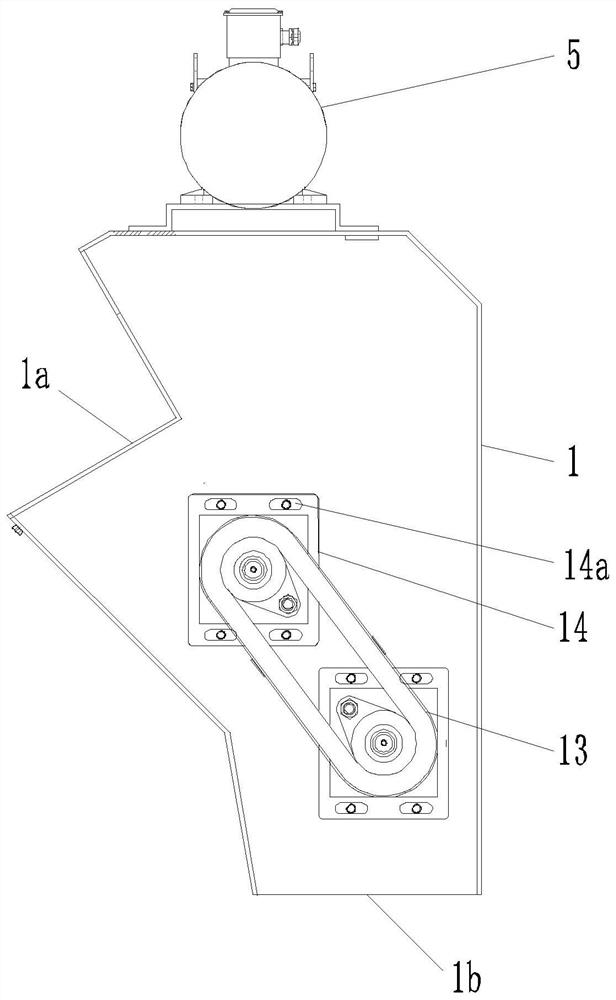

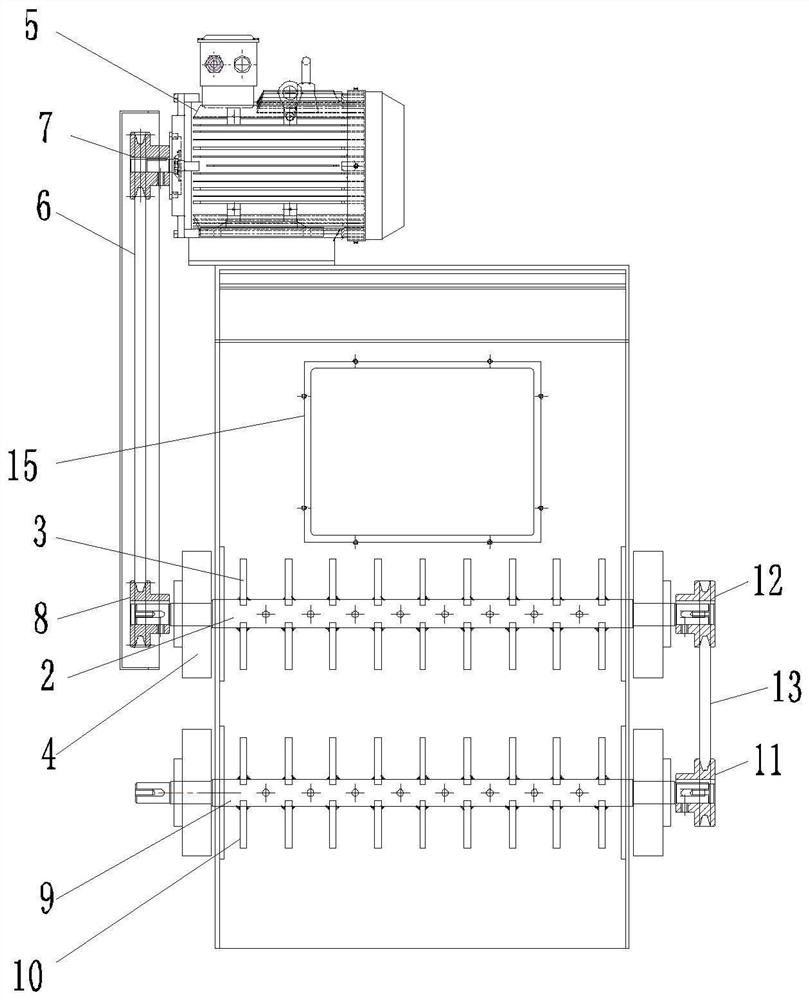

[0027] Such as Figure 1~2 As shown, a device for crushing tea stems and connecting buds includes a hopper, and the hopper is provided with a feed inlet and a discharge port; the first broken stem shaft and the first broken stem rod are arranged in the described hopper, and the described hopper A plurality of first crushed stem rods are evenly arranged along the first crushed stem shaft, and the two ends of the first crushed stem shaft are fixed on the side wall of the hopper through a diamond-shaped bearing seat, and a bearing is arranged in the diamond-shaped bearing seat. One end of the first broken stem shaft is connected with the driving mechanism.

[0028] Specifically, the drive mechanism includes a motor, a V-belt belt 1, a first pulley and a second pulley, the first pulley is fixed on the output shaft of the motor, and the second pulley is fixed on the first broken stem shaft, First pulley and second pulley are connected by V-belt belt 1; Described motor is fixed on ...

Embodiment 2

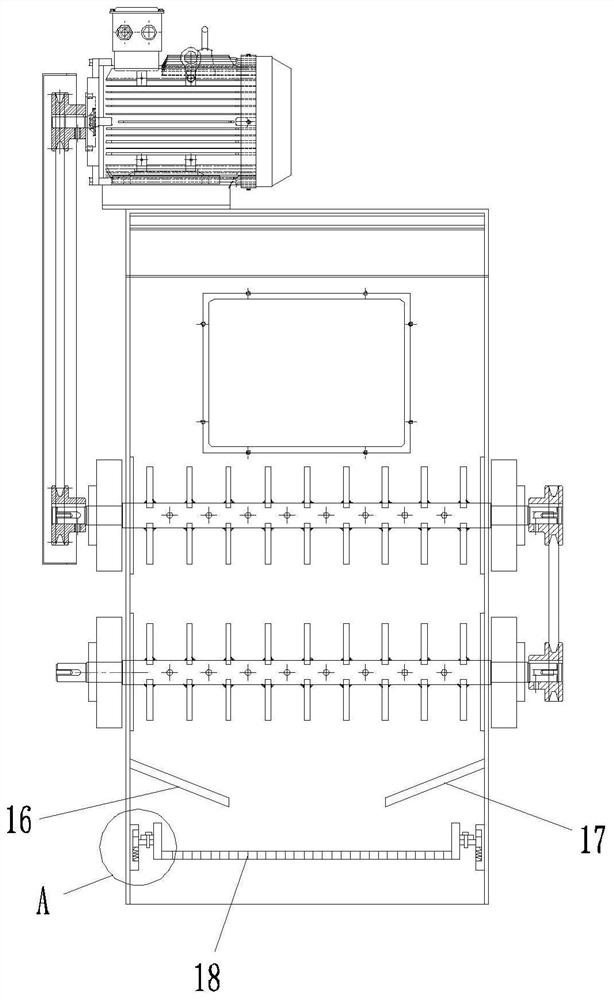

[0035] Such as Figure 3-4 Shown, on the basis of embodiment 1, increase following structure:

[0036] A first guide plate and a second guide plate arranged obliquely are also arranged in the hopper. A filter frame is set under the first guide plate and the second guide plate, the bottom plate of the filter frame is a filter plate, the left and right sides of the filter frame are set with first horizontal plates, and the inside of the hopper is set to install plate, the mounting plate is fixed on the side wall of the hopper; a chute is set in the mounting plate, a slider is set in the chute, a second horizontal plate is set on the slider, and the first horizontal plate and the second horizontal plate are fixed by screws together; the bottom surface of the slider is fixed on the bottom of the chute by a spring.

[0037] By setting the filter frame, the crushed tea leaves are screened, so that the tea classification is more detailed, and the connection between the filter frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com