Zigzag inclined rod type continuous bending machine

A technology of bending machine and bending mechanism, which is applied in the field of machinery, can solve the problems of large volume, complicated operation, and low efficiency, and achieve the effects of reducing equipment volume, compact overall structure, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

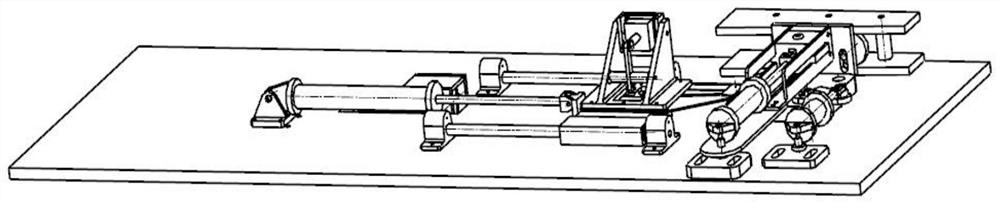

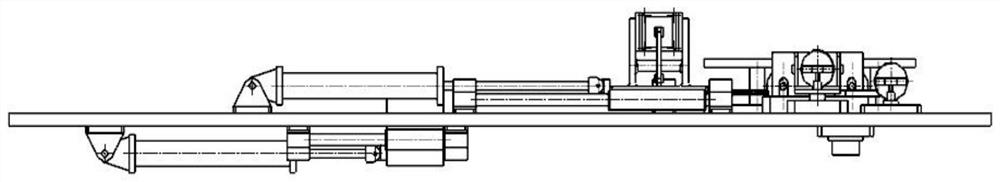

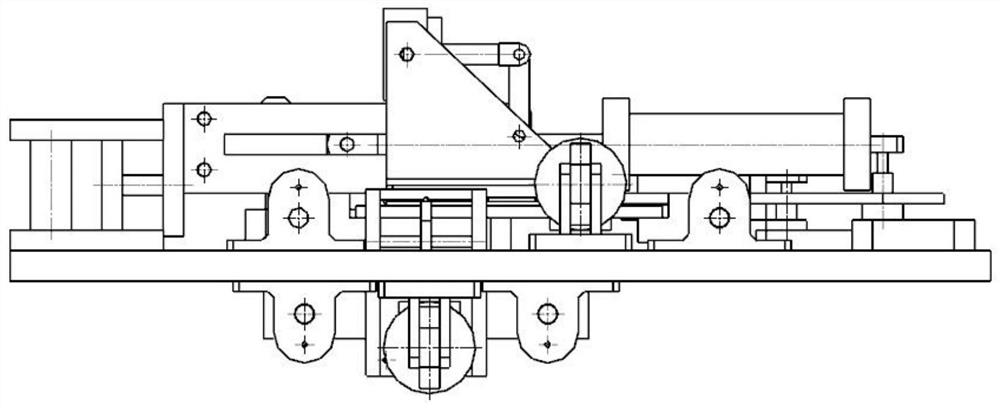

[0028] See Figure 1-10 In the present embodiment, a zigzag bevel continuous bending machine includes a feed mechanism, a follow-up mechanism, and a bending mechanism mounted on the table 50, and the feed mechanism will be bent behind the steel wire. Adjusted, the follow-up mechanism achieves forward follow-up during the steel wire 49 bending process, the bending mechanism to bend the wire 49, the follow-up mechanism is located at the end of the feed mechanism, the bending mechanism is located The end of the follow-up mechanism includes the bending gas cylinder 31, the connecting plate 32, the bend rail left 33, the retractable pin 34, the slider 35, the bearing cover 36, the rolling bearing 37, the bearing plate 38, bend rail right 39. The retractable push push cylinder 41, the baffle advances the cylinder 43, the bent pin 46, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com