Magnetic powder injection molding binder, preparation method and application method

A technology of injection molding and application method, applied in the field of magnetic powder injection molding binder and preparation, can solve the problems of undisclosed addition amount and removal effect, and achieve the effect of good injection molding effect, good rolling property and reducing carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

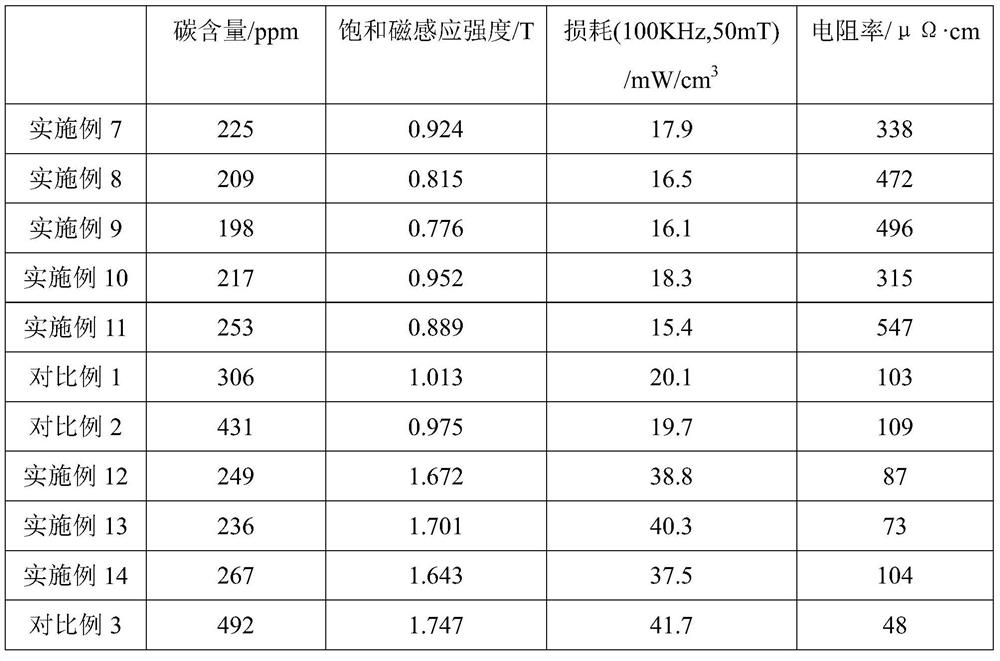

Examples

Embodiment 1~5

[0025] Embodiment 1~5 prepares binding agent

Embodiment 1

[0027] Spherical nano-silica is selected, with an average particle size of 50nm.

[0028] Ultrasonically disperse 1.5 parts of spherical nano-silica in 200 parts of gasoline, add 60 parts of paraffin and mix evenly, remove gasoline, add 25 parts of HDPE, 1.5 parts of stearic acid and 12 parts of EVA, heat to 140 ° C and stir and mix evenly to obtain Adhesive, denoted as A-1.

Embodiment 2

[0030] Spherical nano-silica is selected, with an average particle size of 50nm.

[0031] Ultrasonic disperse 5 parts of spherical nano-silica in 200 parts of gasoline, add 60 parts of paraffin and mix well, remove gasoline, add 25 parts of HDPE, 1.5 parts of stearic acid and 8.5 parts of EVA, heat to 140 °C and stir to mix evenly to obtain Adhesive, denoted as A-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com