Screw dismounting tool and using method thereof

A technology for dismantling tools and screws, used in manufacturing tools, hand-held tools, workpiece clamping devices, etc., can solve problems such as easily damaged equipment threaded holes, damage to equipment surface structural strength, increase maintenance workload, etc., to achieve uniform force , large contact surface, the effect of eliminating elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

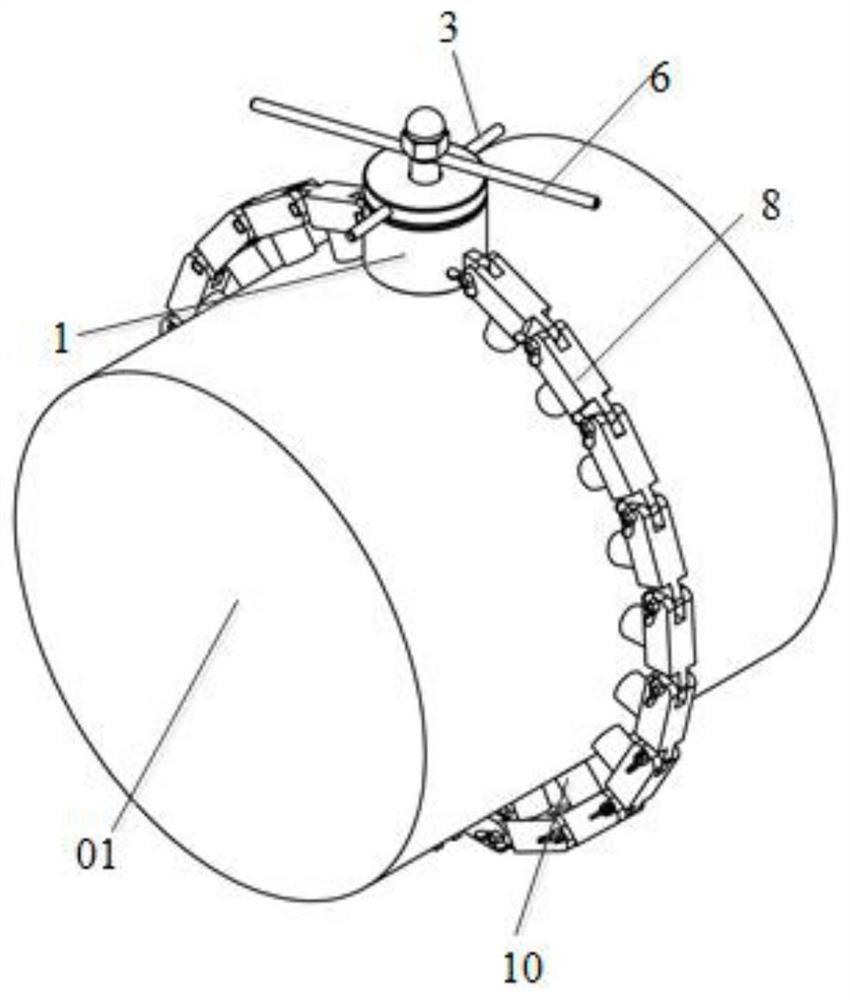

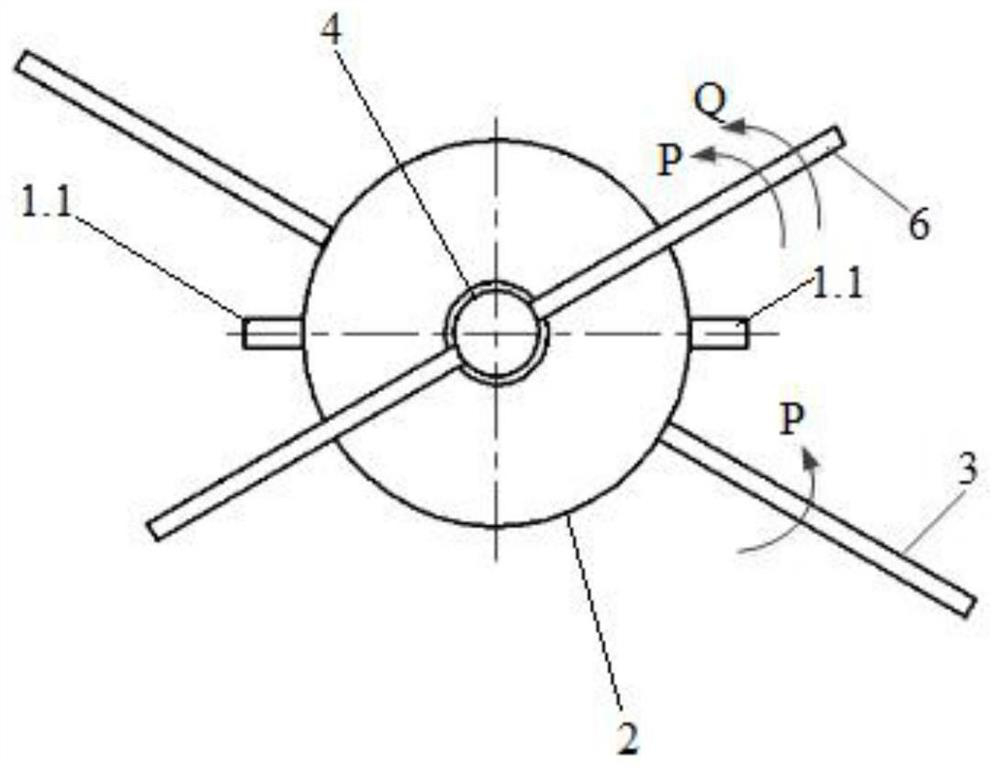

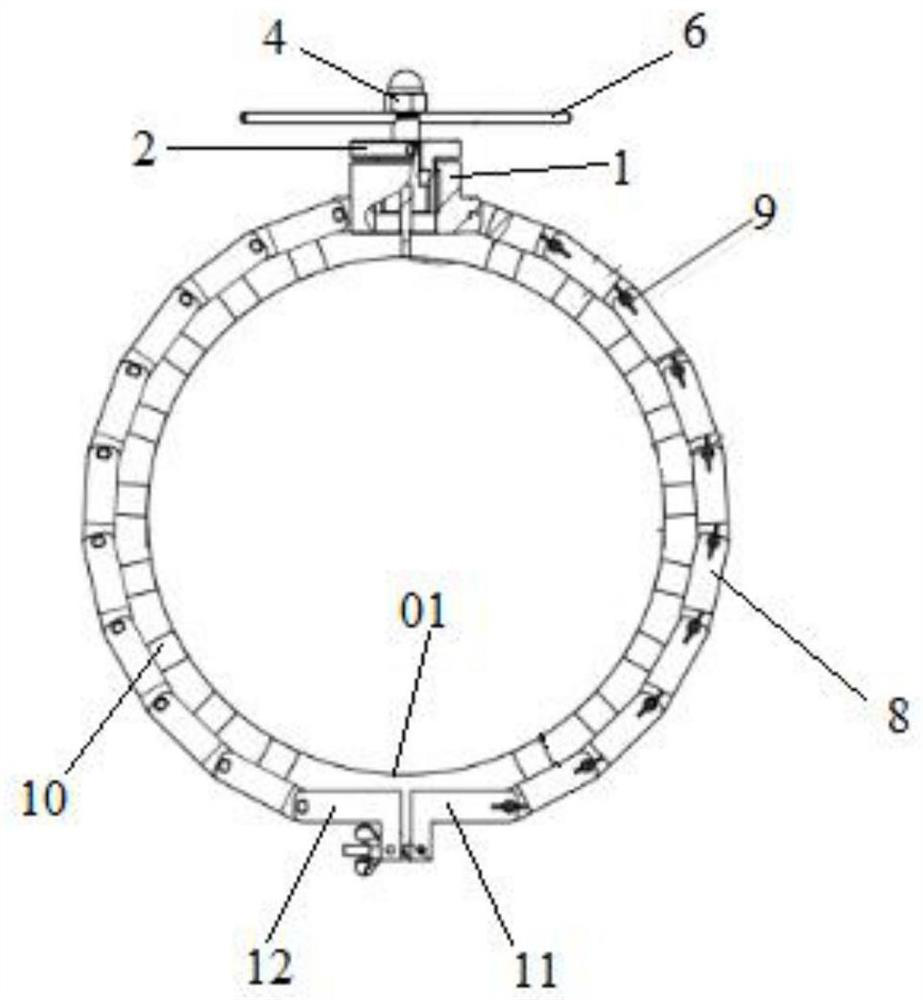

[0054] see Figure 1-3 , a screw removal tool, including a disassembly mechanism, a clamping mechanism and a locking mechanism, the disassembly mechanism includes a shaft sleeve 1 and a rotation control assembly, and the shaft sleeve 1 is arranged on a device (specifically a thin-walled cylindrical shell 01 ) on the position of the screw to be disassembled, the rotation control assembly is threadedly connected to the inner wall of the shaft sleeve 1, and is used to regulate and unscrew the screw to be disassembled on the equipment until the disassembly operation is completed;

[0055] The clamping mechanism includes clamping assemblies respectively arranged on the sleeve 1 and located on both sides of the sleeve 1 (ie, two sets of clamping assemblies) for clamping equipment;

[0056] The locking mechanism is arranged on the end of the clamping assembly away from the shaft sleeve 1, and is used for circumferentially locking the clamping assembly and the dismounting mechanism on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com