Low-temperature pyrolysis method and system

A low-temperature pyrolysis and pyrolysis furnace technology, which is applied in the petroleum industry, coking ovens, etc., can solve problems such as uncontrollable dioxin generation, and achieve the effects of avoiding excessive flue gas temperature, eliminating open flames, and having fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

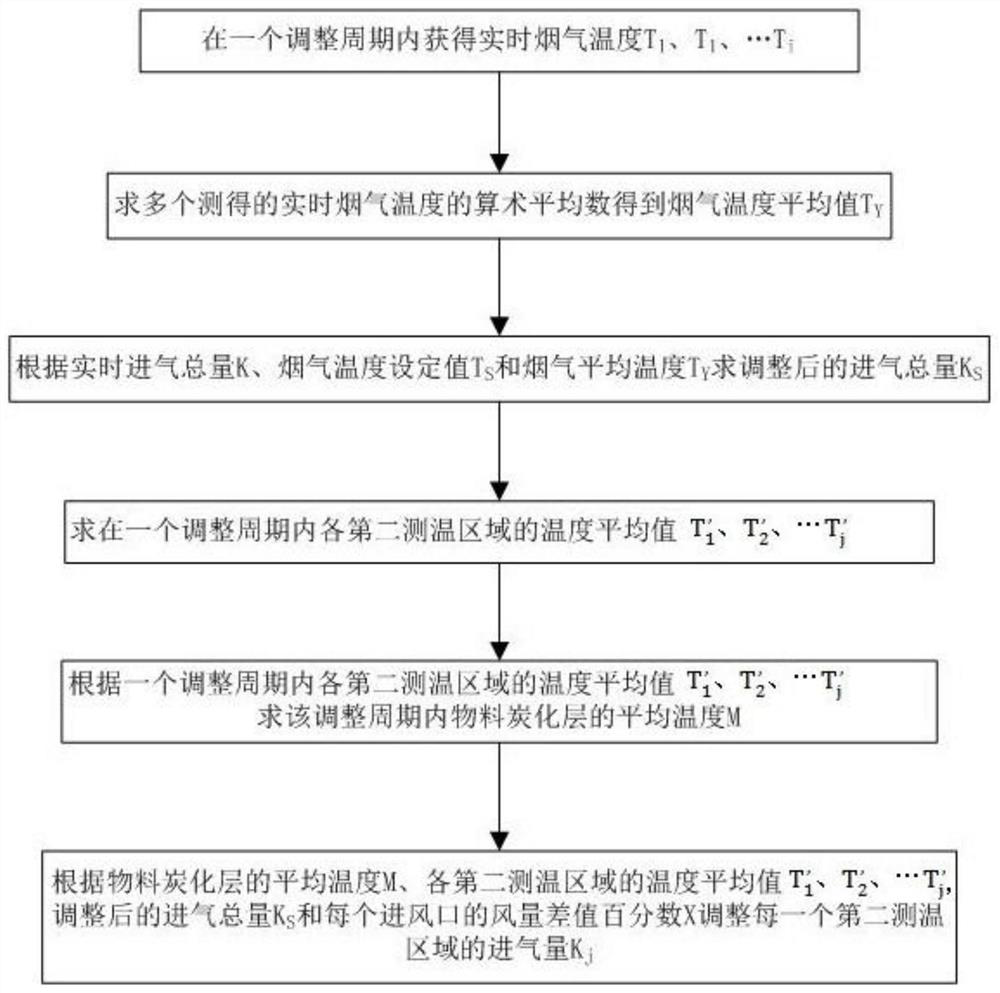

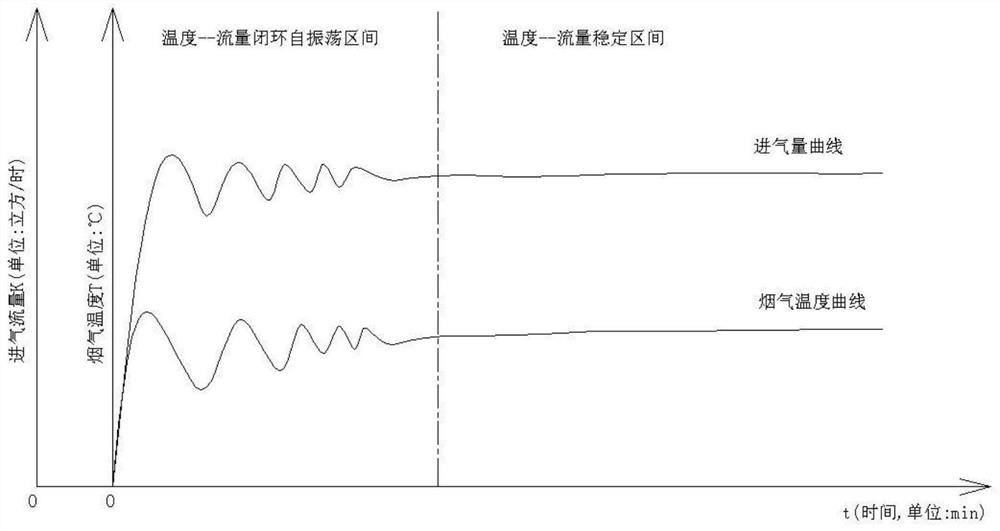

[0047] A low-temperature pyrolysis method according to a preferred embodiment of the present invention, which adjusts the pyrolysis furnace by controlling the total amount of intake air of the pyrolysis furnace and the intake air volume of each area in the pyrolysis furnace according to the temperature of different regions in the pyrolysis furnace The temperature field of the material in the pyrolysis furnace forms a dynamic control to realize the pyrolysis of the material in the pyrolysis furnace without open flame and the control of the flue gas temperature. In this embodiment, the total amount of intake air and the intake air volume of each area are controlled by the temperature of different areas in the pyrolysis furnace, and the obtained temperature in different areas of the pyrolysis furnace can have a complete and comprehensive effect on the thermal field in the pyrolysis furnace. The overall understanding and overall control can determine whether to increase or decrease...

Embodiment 2

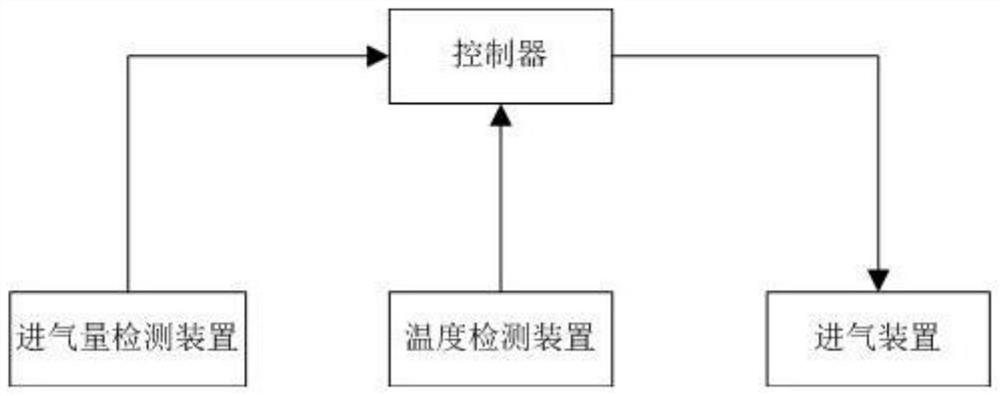

[0092] Such as image 3 As shown, this embodiment provides a low-temperature pyrolysis system for implementing the method of Embodiment 1, including a pyrolysis furnace, a temperature detection device, an air intake device, an intake air volume detection device and a controller, and the temperature detection device is used to detect heat The temperature of different areas in the pyrolysis furnace. The air intake device is used to deliver gas to different areas in the pyrolysis furnace. The temperature detection device, the air intake device and the intake air volume detection device are connected in communication; the controller is used to receive the temperature information of different areas in the pyrolysis furnace detected by the temperature detection device and the temperature information of different areas in the pyrolysis furnace detected by the intake air volume detection device. The intake air volume information, and the total intake air volume is obtained according t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap