Power transmission device with working part height difference compensation function

A technology for power transmission devices and working parts, applied in the direction of transmission devices, transmission device parts, energy-saving measures, etc., can solve the problems of increasing equipment investment costs, increasing the difficulty of daily use management and maintenance, etc., to achieve reasonable structure and save equipment investment costs , the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to be more clearly understood, the applicant will be described in detail in the manner described below, but the description of the present invention is not limited to the embodiments of the present invention. It is only the technical solution category of the present invention only for the form of the present invention.

[0021] In the following description, the concept involving the direction, lower, left, and right, and then rear, and the corresponding direction is based in addition to the other description. figure 1 The state is based, and thus it is not understood to be particularly limited in the technical solutions provided by the present invention.

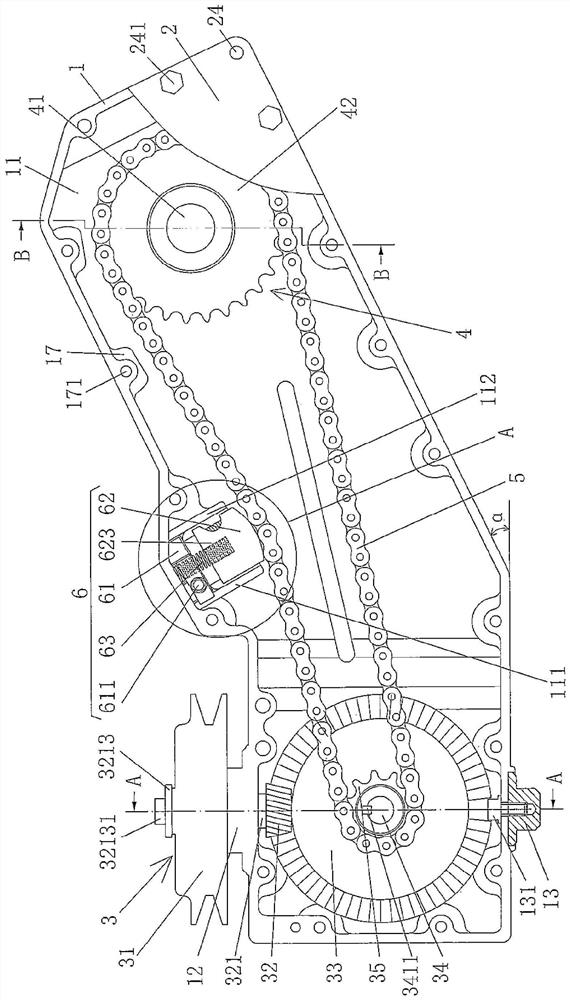

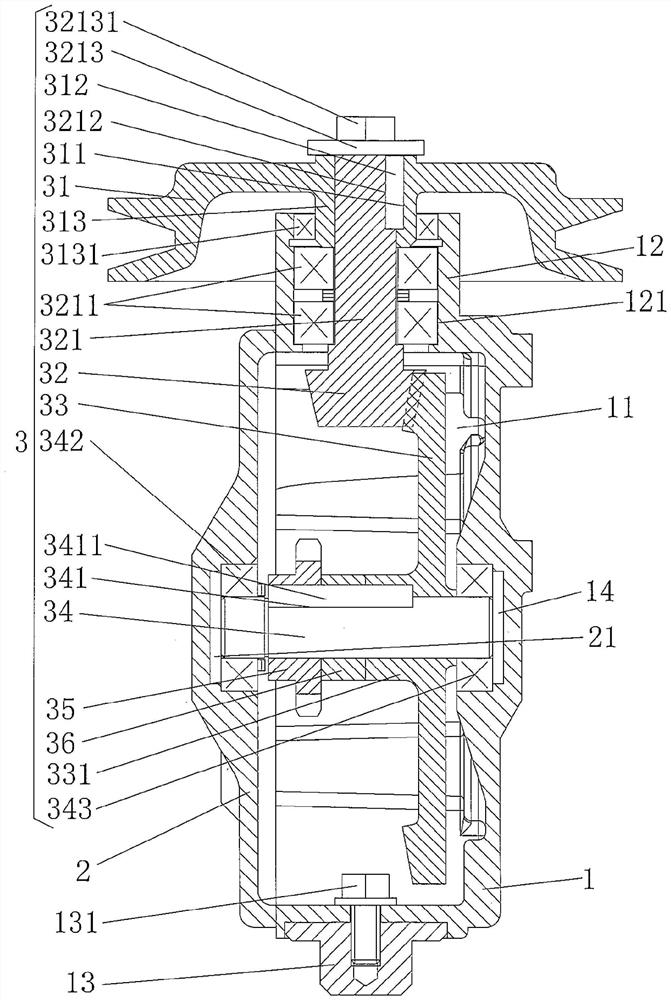

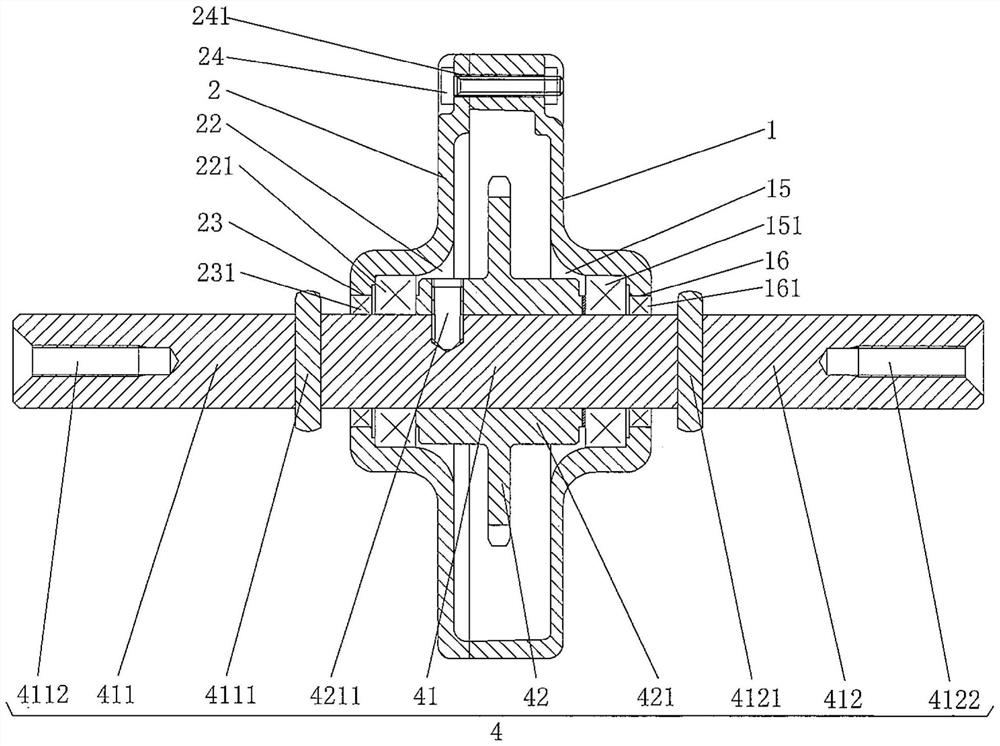

[0022] See figure 1 A replacement case housing 1 and a replacement case cover 2 are shown, and the replacement case housing 1 has a housing chamber 11, the replacement case cover 2 is corresponding to the position of the casing cavity 11 and the gear case housing. 1 fixed; showing a power input transmission mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com