Pipeline crossing pushing system for narrow deep valley or wide river and process of pipeline crossing pushing system

A technology of jacking and deep valley, which is applied in the direction of pipeline supports, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc. It can solve the problems that large-scale hoisting equipment cannot be hoisted in place at one time, and achieve the effect of increasing safety control capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

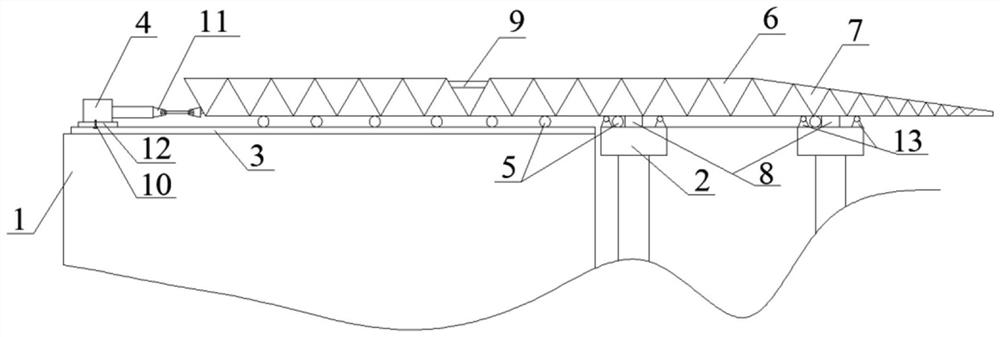

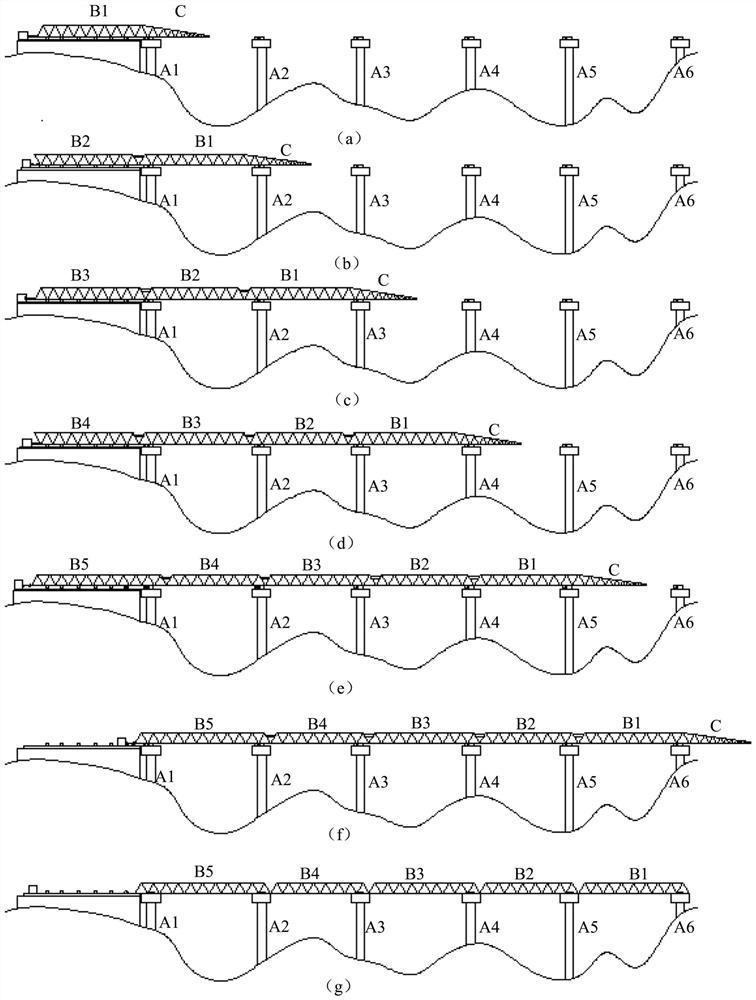

[0037] Hereinafter, the pipeline crossing jacking system for narrow deep valleys or wide rivers and its process will be described in detail with reference to exemplary embodiments and drawings. Herein, "first" and "second" are only for convenience of description and distinction, and cannot be understood as indicating or implying relative importance or having a strict sequence.

[0038] The present invention adopts a small-section light structure, that is, the pipe truss pushes and sends the leading span structure, which is installed at the front end of the first truss to ensure that the leading span structure is already in place before the center of gravity moves to the cross section range during the first truss sending process. On the truss pier spanning the front end of the section, the subsequent trusses can be continuously pushed to the design position when they are in place. The present invention adopts the jacking system designed with the characteristics of the truss in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com