Preparation method of water-soluble soybean polysaccharide

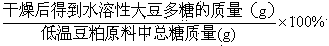

A soybean polysaccharide and water-soluble technology, which is applied in the field of microwave-ultrasonic collaborative technology to extract water-soluble soybean polysaccharides, can solve the problems of low extraction rate, long time, high energy consumption, etc., and achieve the effect of easier leaching and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of preparation method of water-soluble soybean polysaccharide specifically comprises the following steps:

[0049] (1) Add 1L of water to 100g of low-temperature soybean meal, stir and mix well, adjust the pH to 8.50 with 1M sodium hydroxide, control the extraction temperature to 55°C, and the time to 42.8min. After the extraction is completed, control the speed to 4000r / min. After centrifuging for 20 minutes, the supernatant was precipitated to obtain the soybean protein isolate fraction, and the wet residue was retained as a raw material for extracting water-soluble soybean polysaccharides;

[0050] (2) Add 0.3L of water to the above wet residue, stir evenly, adjust the pH of the extract to 2.0 with 1M hydrochloric acid, and obtain a reaction solution;

[0051] (3) Place the reaction solution obtained in step (2) in a microwave-ultrasonic assisted extractor, set the microwave extraction power to 275w, the ultrasonic extraction power to 160w, and set the extract...

Embodiment 2

[0059] A kind of preparation method of water-soluble soybean polysaccharide specifically comprises the following steps:

[0060] (1) Add 3L of water to 300g of low-temperature soybean meal raw material and stir evenly, adjust the pH to 8.50 with 1M sodium hydroxide, control the extraction temperature to 55°C, and the extraction time to 42.8min. After the extraction is completed, control the rotation speed to 4000r / min , the time is 20min to carry out centrifugation, the supernatant is precipitated to obtain the soybean protein isolate component, and the wet residue is retained as the raw material for extracting the water-soluble soybean polysaccharide;

[0061] (2) Add 1.5 L of water to the wet residue obtained in step (1), stir evenly, and adjust the pH to 6.8 with 1M hydrochloric acid to obtain a reaction solution;

[0062] (3) Place the reaction solution obtained in step (2) in a microwave-ultrasonic assisted extractor, set the microwave extraction power to 275w, the ultras...

Embodiment 3

[0068] A kind of preparation method of water-soluble soybean polysaccharide specifically comprises the following steps:

[0069] (1) Add 2L of water to 200g of low-temperature soybean meal raw material and stir evenly, adjust the pH to 8.50 with 1M sodium hydroxide, control the extraction temperature to 55°C, and the time to 42.8min. After the extraction is completed, control the rotation speed to 4000r / min , centrifuged for 20 minutes, and the supernatant was precipitated to obtain the soybean protein isolate component, and the wet residue was retained as the raw material for extracting the water-soluble soybean polysaccharide;

[0070] (2) Add 1.2L of water to the wet residue obtained in step (1), stir evenly, and adjust the pH to 7.5 with 1M hydrochloric acid to obtain a reaction solution;

[0071] (3) Place the reaction solution obtained in step (2) in a microwave-ultrasonic assisted extractor, set the microwave extraction power to 275w, the ultrasonic extraction power to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com