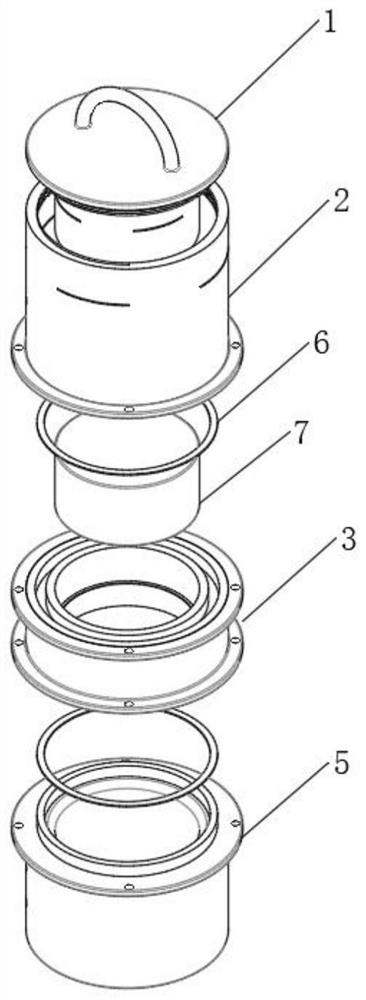

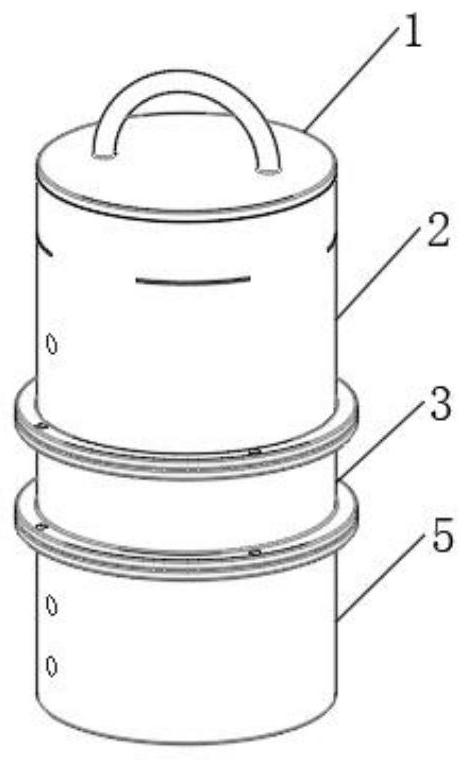

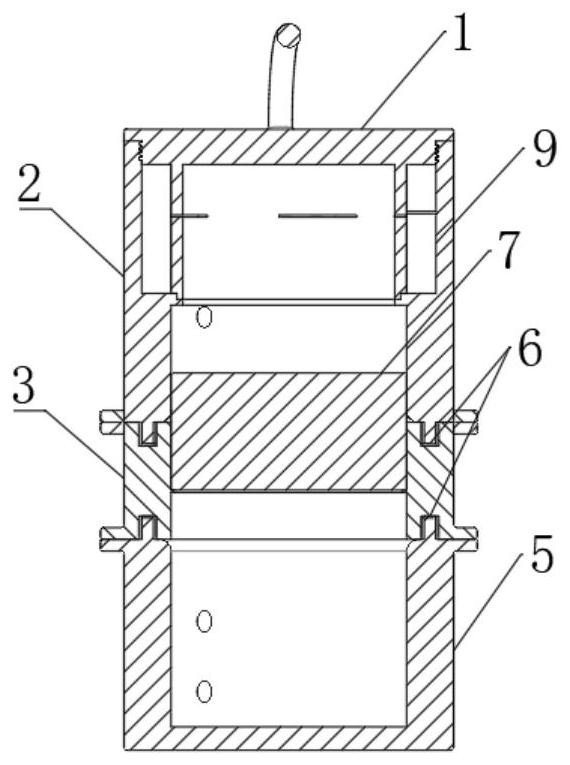

Steady-state flow resistance measuring cylinder for porous sound absorption material

A technology of porous sound absorption and measuring cylinder, applied in the direction of analyzing materials, analyzing solids using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the difference of original flow resistance value of materials, increase the measurement error, cannot correctly guide sound absorption and noise reduction, etc. problems, to achieve the effect of easy disassembly, simple structure, and easy rapid estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0045] Embodiment 1 and Embodiment 2 Aiming at two different types of porous sound-absorbing materials, the present invention integrates the measurement of their steady-state flow resistance into one body, broadens the measurement range, and provides practical solutions for the measurement of the steady-state flow resistance of porous sound-absorbing materials outside the laboratory. The application scenarios have been expanded to provide convenience for life and production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com