Electrolytic hydrogen production rectification power supply based on high-transformation-ratio transformer and control method

A technology of rectifying power supply and control method, which is applied in the electrolysis process, electrolysis components, conversion of AC power input to DC power output, etc., can solve the problems of inability to produce hydrogen with high power, large power output ripple, and low hydrogen production efficiency. , to achieve the effect of reducing the amount of use, small output current ripple, and high hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings, but the scope of the invention is not limited to the following.

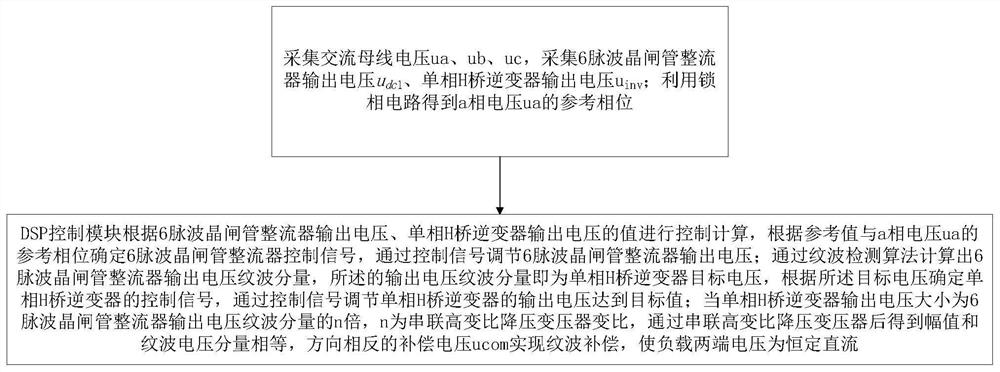

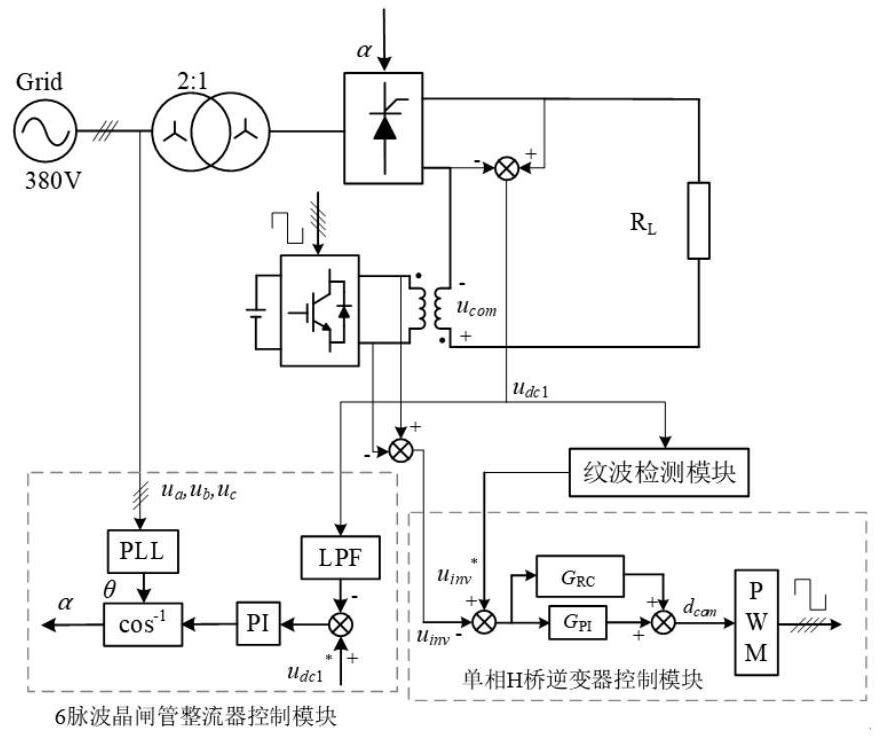

[0025] like figure 1 As shown, the control method of electrolytic hydrogen rectifier power supply based on high-variable transformer, including the following procedure:

[0026] Acquisition of AC bus voltage UA, UB, UC, collect 6 pulse wavelength ganker rectifier output voltage U dc1 , Single-phase H-bridge inverter output voltage U inv The reference phase of the A phase voltage UA is obtained by the phase-locked circuit;

[0027] The DSP control module performs control calculation according to the value of the 6 pulse-thyristor rectifier output voltage, and the value of the single-phase H bridge inverter output voltage is controlled. According to the reference phase of the reference value and the reference phase of the A-phase voltage UA, the 6 pulse wavelength gate tube rectifier c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com