Turbomolecular vacuum pump and purging method

A turbomolecular and vacuum pump technology, applied to pumps, pump components, axial flow pumps, etc., to achieve the effect of prolonging time and increasing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following embodiments are examples. Although the description refers to one or more embodiments, this does not necessarily mean that every reference refers to the same embodiment or that a feature applies uniquely to a single embodiment. Individual features of various embodiments can be equally combined or interchanged to form other embodiments.

[0039] "Upstream" means that one element is located before another element with respect to the direction of gas circulation. Conversely, "downstream" means that one element is located behind another element with respect to the direction of circulation of the gas to be pumped, the upstream element being at a lower pressure than the downstream element.

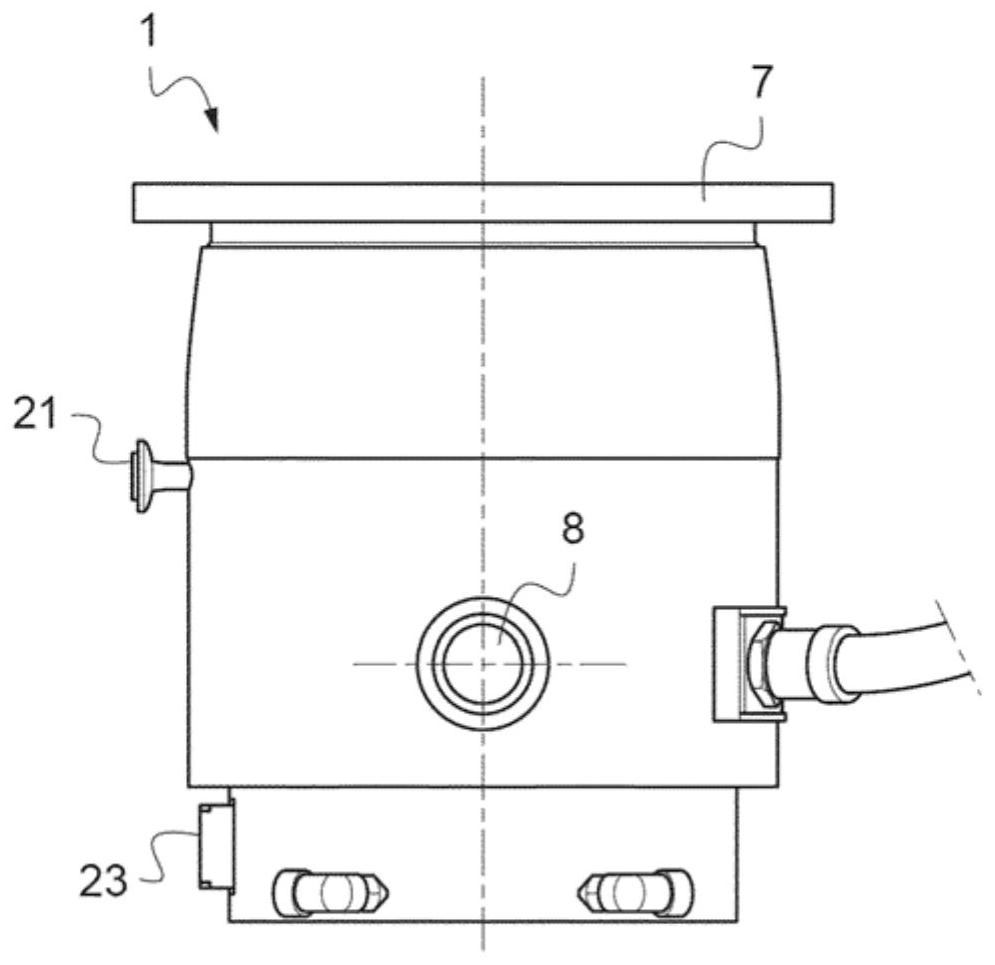

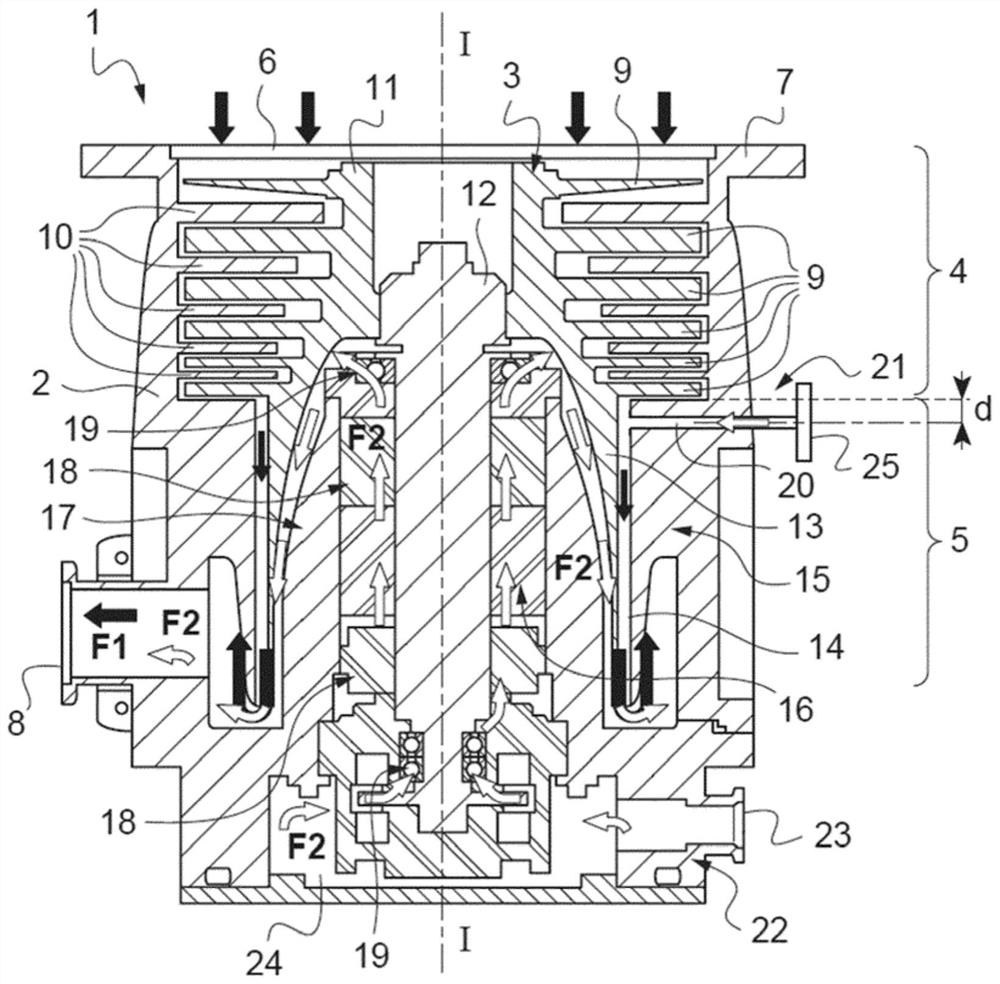

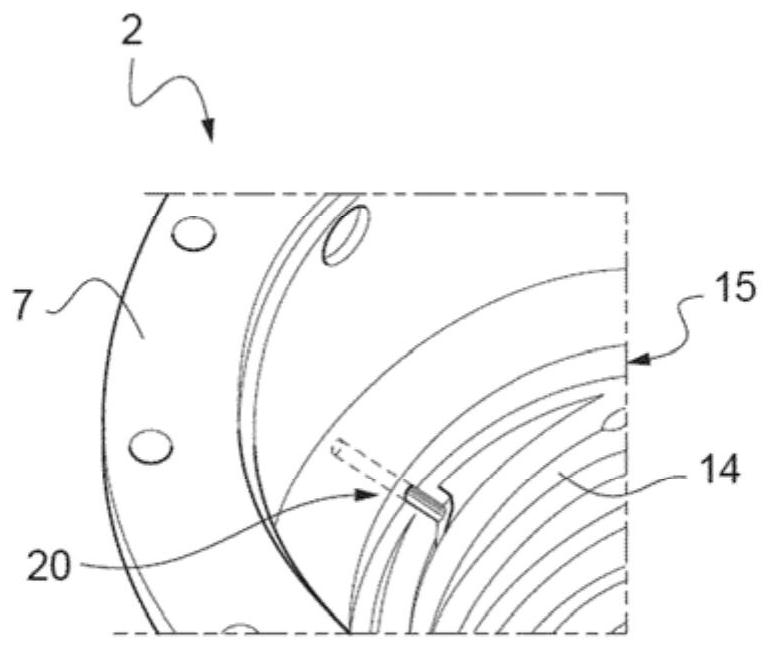

[0040] figure 1 and figure 2 A first embodiment of a turbomolecular vacuum pump 1 is shown.

[0041] The turbomolecular vacuum pump 1 includes a stator 2 in which a rotor 3 is configured to rotate axially at high speed, for example at a speed exceeding 20,000 revolutions...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap