Hydraulic self-adaptive driving control system of hydraulic variable-diameter threshing cylinder and self-adaptive control method

A technology of self-adaptive control and threshing drum, applied in fluid pressure actuation system components, threshing equipment, applications, etc., can solve the problem of inability to adjust the drum in real time, change the threshing gap, etc., to improve the degree of automation and harvesting efficiency, prevent clogging , to achieve the effect of load protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

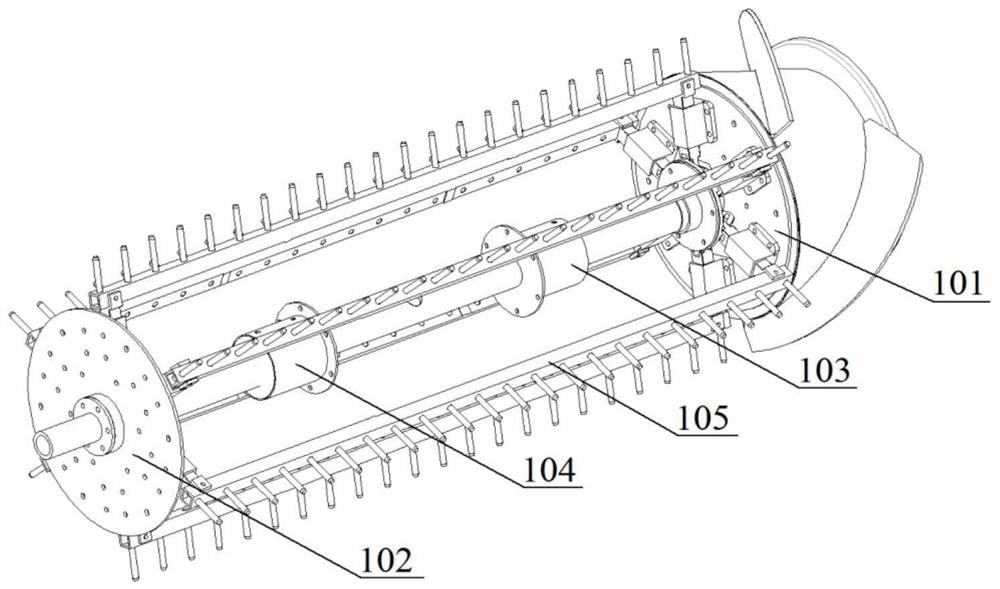

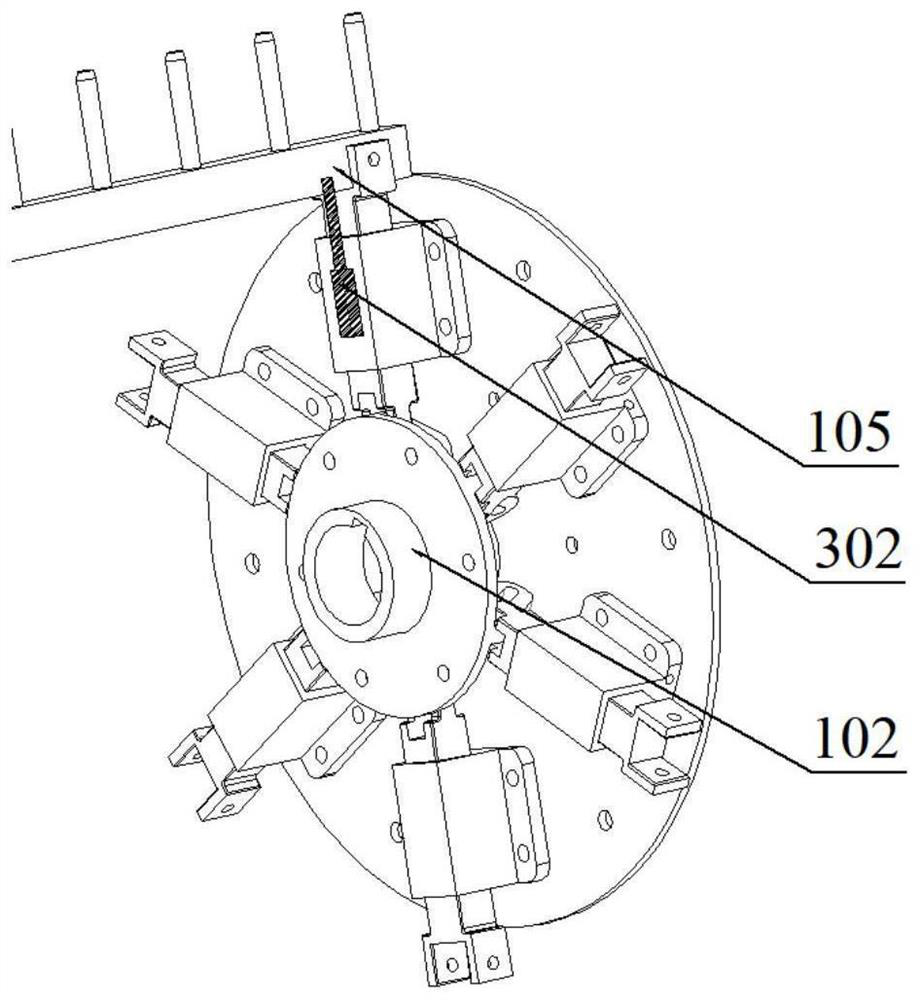

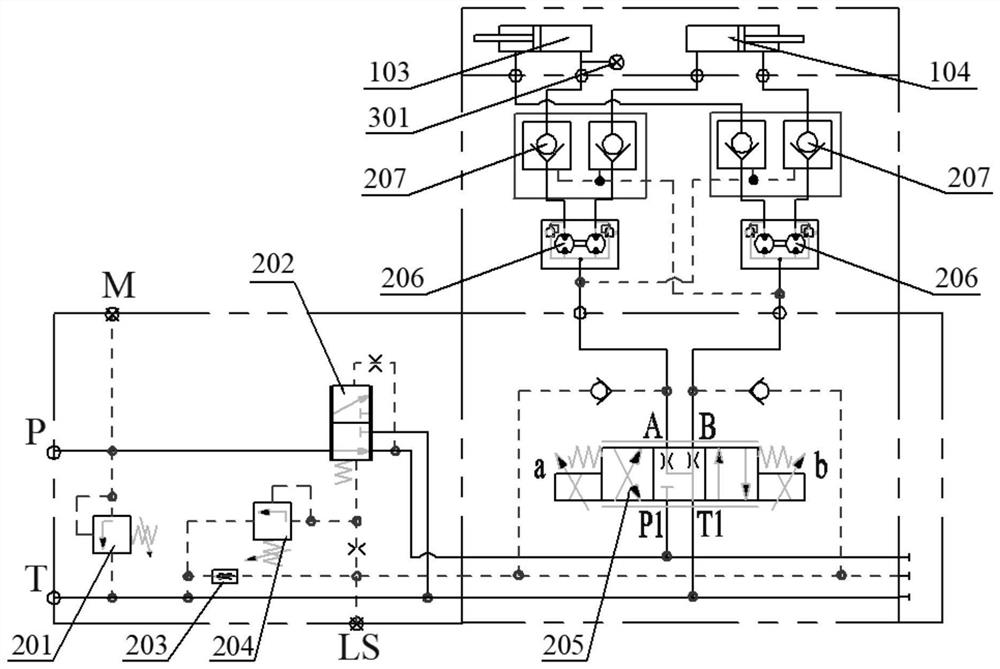

[0037] Such as figure 1 and figure 2As shown, the simplified structure of the hydraulic variable diameter threshing drum includes a feed-end diameter adjustment device 101 , a tail-end diameter adjustment device 102 , a feed-end hollow hydraulic cylinder 103 , a tail-end hollow hydraulic cylinder 104 , and a threshing gear rod 105 . Feeding-end diameter adjusting device 101, tail-end diameter adjusting device 102, feeding-end hollow hydraulic cylinder 103, and tail-end hollow hydraulic cylinder 104 are all coaxial with the drum main shaft, threshing gear rod 105 and feeding-end diameter adjusting device 101, The gear rod connecting rod of the tail end diameter adjusting device 102 is fixed by bolts and nuts, and the expansion and contraction of the piston rod of the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com