Three-way pipe welding equipment with self-sealing detection function

A technology for welding equipment and tee pipes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing the production process of tee pipes, wasting manpower and material resources, etc., to reduce production processes and save money. The effect of manpower and material resources and convenient sealing detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

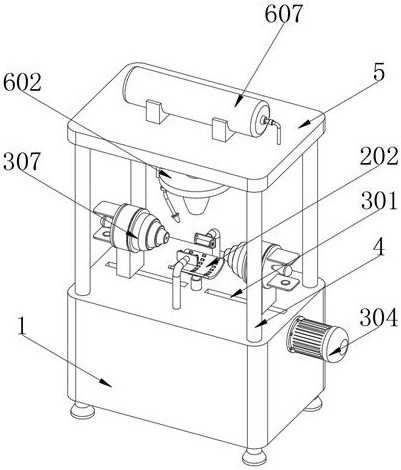

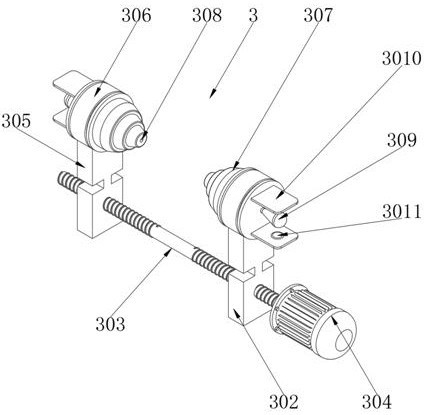

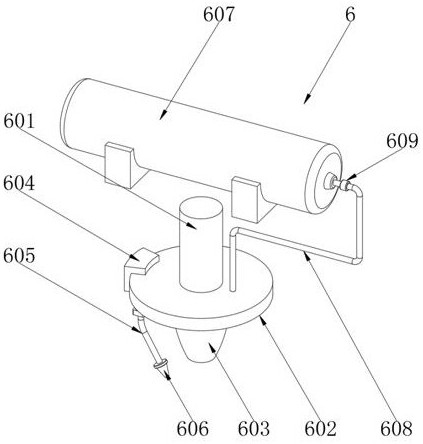

[0051] Example: such as Figure 1-7 As shown, the present invention provides the following technical solutions, a kind of tee pipe welding equipment with self-sealing detection function, the welding equipment includes a welding station 1, and the welding station 1 is provided with an adjustment assembly 2 for adjusting the position of the pipeline and The fixing component 3 for fixing the adjusted pipeline, the support plate 5 is installed on the welding table 1 through the support column 4, and the clamping detection component 6 for clamping and sealing detection of the pipeline is installed under the support plate 5.

[0052] As a preferred technical solution, the alignment assembly 2 includes a first telescopic rod 201, an alignment arc plate 202, an alignment roller 203 and a driving alignment mechanism 204;

[0053] The middle part of the upper surface of the welding table 1 is provided with a first telescopic rod 201, and the first telescopic rod 201 is provided with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com