High-elasticity small-particle hollow sphere and preparation process thereof

A technology of hollow balls and high elasticity, which is applied in the field of materials for manufacturing comfortable impact and high-elasticity molding products, and can solve the problems that cannot be directly applied to products, are difficult to apply, and have large diameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

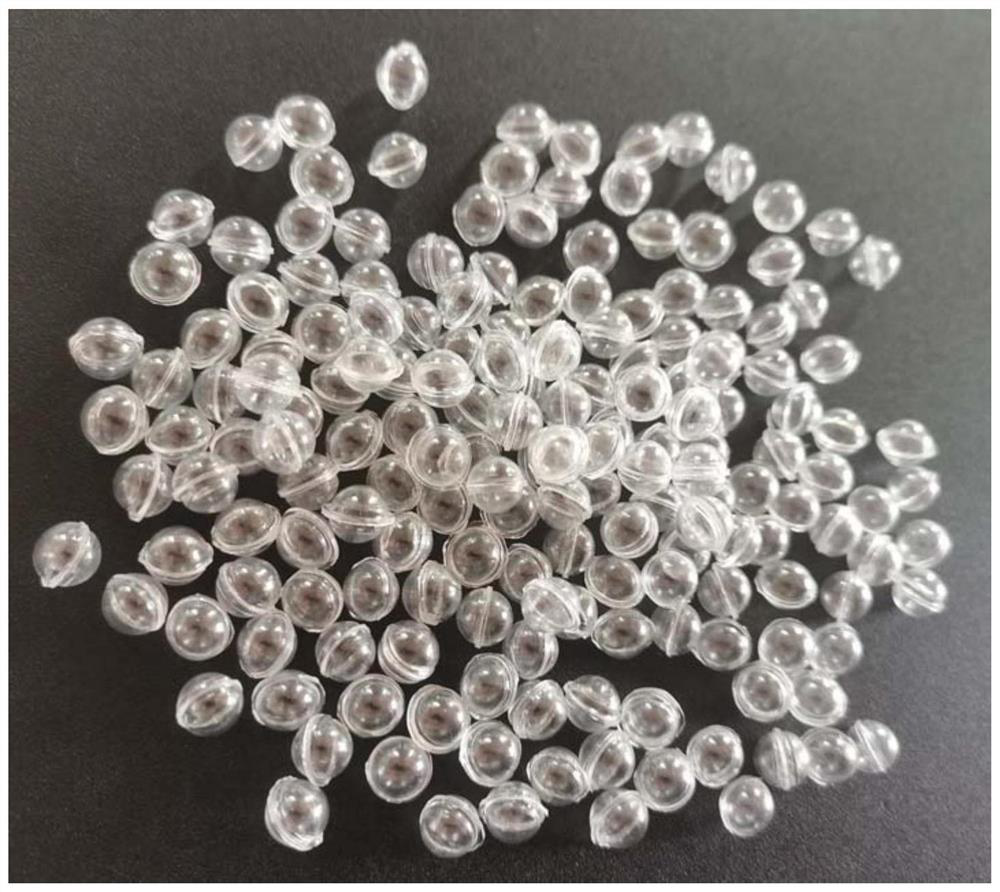

[0031] This embodiment provides a preparation process of high-elastic small-particle hollow spheres and the prepared high-elastic small-particle hollow spheres.

[0032] The process of preparing high-elastic small-particle hollow spheres in this embodiment is as follows:

[0033] S1: Dehumidifying and drying the thermoplastic resin particles through a dehumidifier; wherein the plastic resin particles are TPU or PVC.

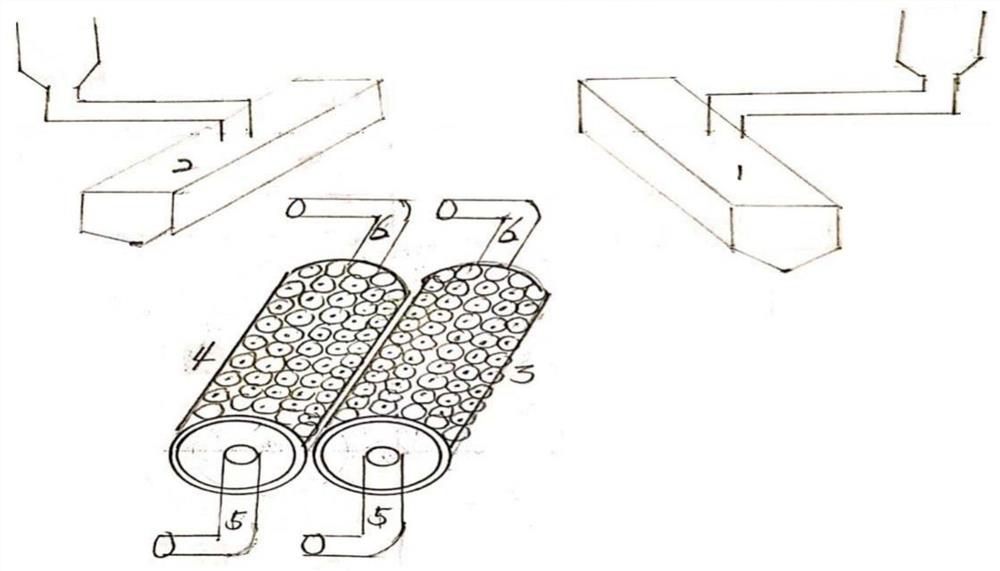

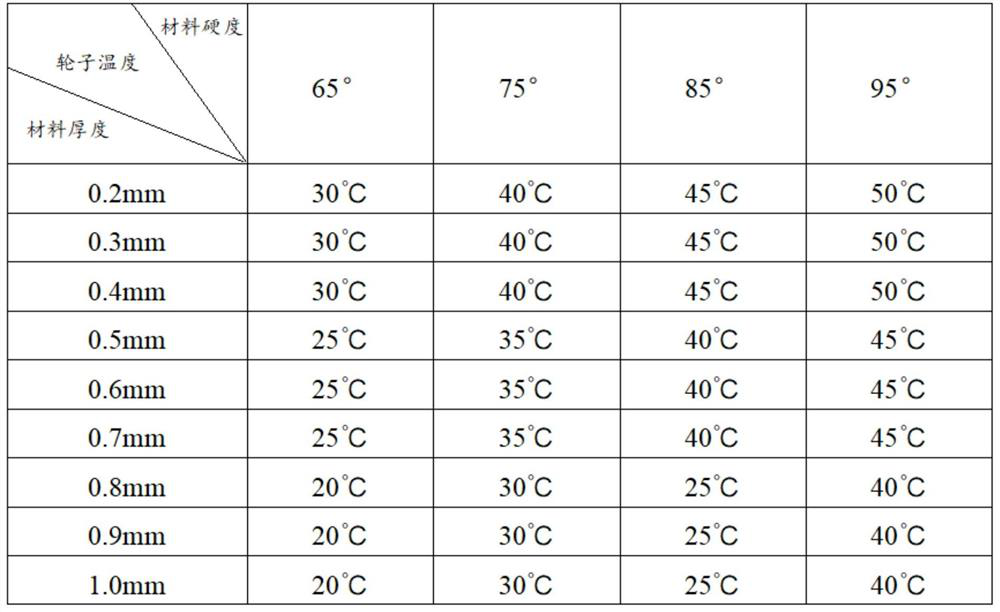

[0034] S2: Extrude the dried thermoplastic resin pellets using two opposite extruders (1, 2) to form two films respectively, wherein the temperature setting of the extruder depends on the thermoplastic resin pellets Due to the difference in hardness, the temperature set in different sections of the extruder is different, as shown in Table 1; by adjusting the die gap at the discharge port, the thickness of the film is adjusted, and the thickness of the film is controlled to be 0.2mm~1.0mm.

[0035] Table 1 Correspondence between the hardness of raw materials and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com