Hydraulic retarder control system

A technology of hydraulic retarder and control system, applied in hydraulic brakes, hydraulic resistance brakes, brake types, etc., can solve problems such as inability to quickly control the accuracy of water temperature, unfavorable driver operation, and decrease in retarder torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

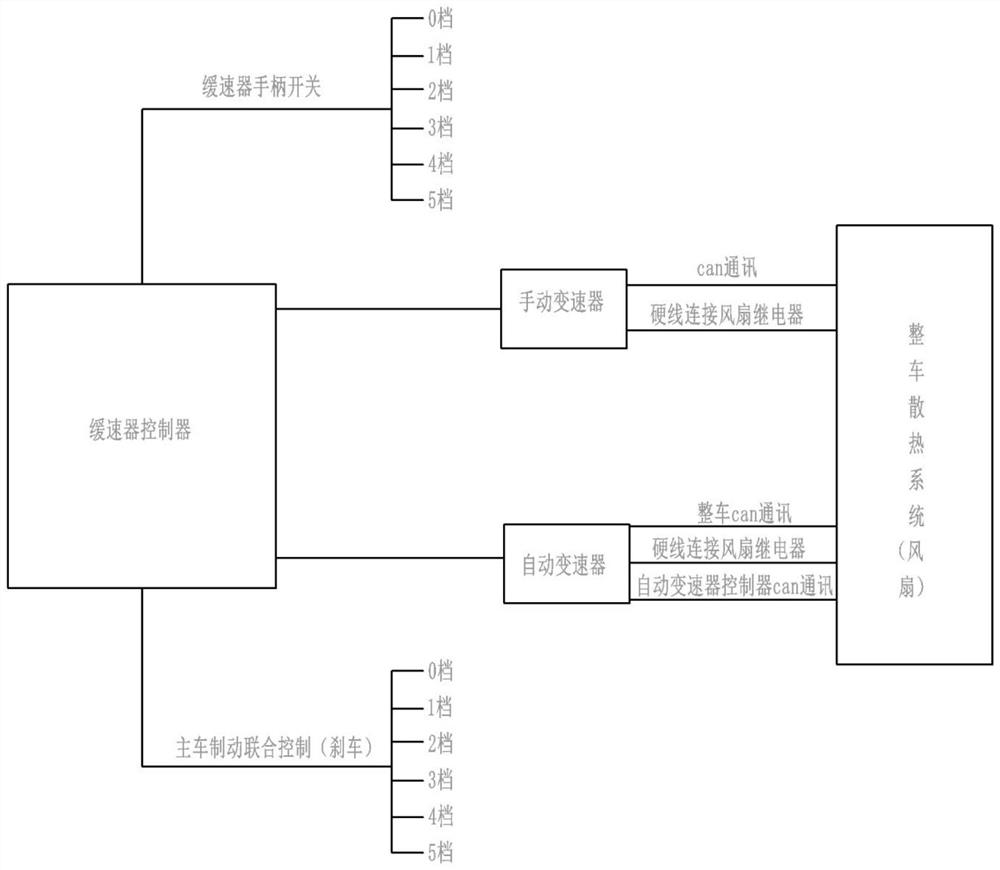

[0026] Basic as attached figure 1 Shown: a hydraulic retarder control system, including a retarder controller, a retarder handle switch, a main vehicle braking system and a complete vehicle cooling system.

[0027] In this embodiment, the retarder controller is the controller ECU, and the retarder handle switch is provided with several gears, and the several gears are: 0 gear, 1 gear, 2 gear, 3 gear, 4 gear, and 5 gear. The retarder handle switch is installed on the right side of the car dashboard or on the right side of the steering wheel (not shown in the figure).

[0028] The main vehicle braking system is an existing automobile braking system. This embodiment is: a braking system. The braking system includes a brake light for prompting the opening and closing of the main vehicle braking system. The braking system has 0 gears, 1 gears, and 2 gears. , 3rd gear, 4th gear, 5th gear, the braking strength of different gears is different. The vehicle heat dissipation system is ...

Embodiment 2

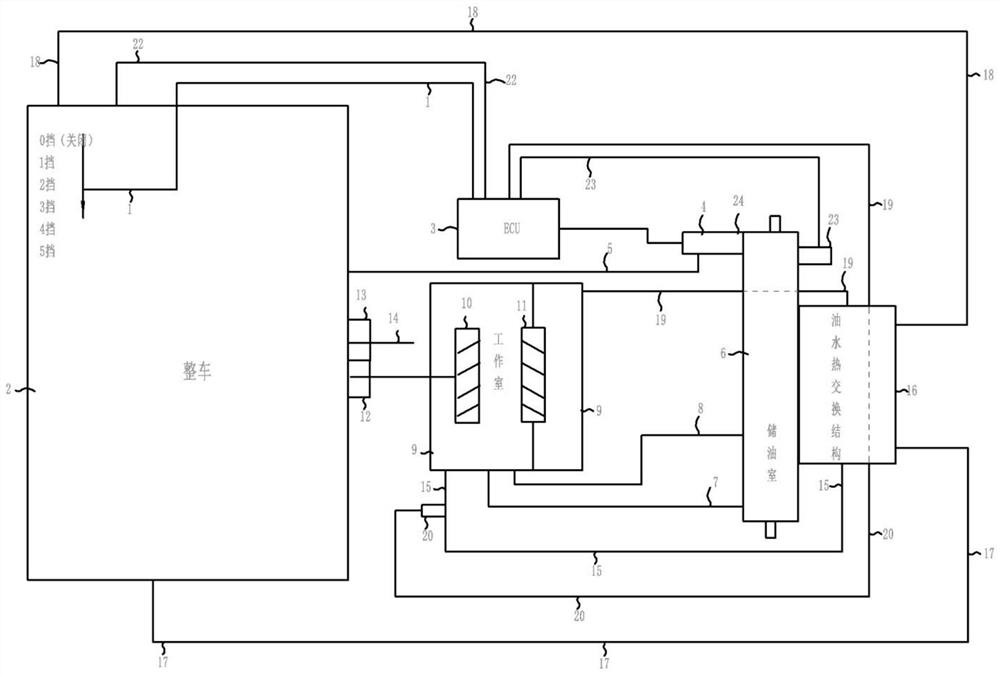

[0039] The difference between embodiment two and embodiment one is that, as attached figure 2 As shown, the retarder controller in this embodiment is the controller ECU3, and the retarder handle switch 1 is installed on the right side of the automobile instrument panel or on the right side of the steering wheel. The electromagnetic proportional valve 4 between the transmission and the vehicle, the electromagnetic proportional valve 4 communicates with the air system of the vehicle cooling system through the pipeline 5.

[0040]The electromagnetic proportional valve 4 communicates with the oil storage chamber 6 of the hydraulic retarder. In the present embodiment, the upper part of the oil storage chamber 6 is a cavity, and a pressure detection device 23 electrically connected to the controller ECU3 is installed in the cavity (pressure sensor), the oil storage chamber 6 below is an oil storage chamber, the cavity is provided with an exhaust port 24, and an air outlet valve is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com