Vacuum blood sampling test tube compounding machine and compounding method

A technology for vacuum blood collection and test tube, which is applied in the field of vacuum blood collection tubes, can solve the problems of inability to discharge the vacuum blood collection tubes and caps, reduce the efficiency of vacuum blood collection tubes and caps, and increase the labor force of staff, so as to prevent low efficiency and increase Workload, the effect of reducing the labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

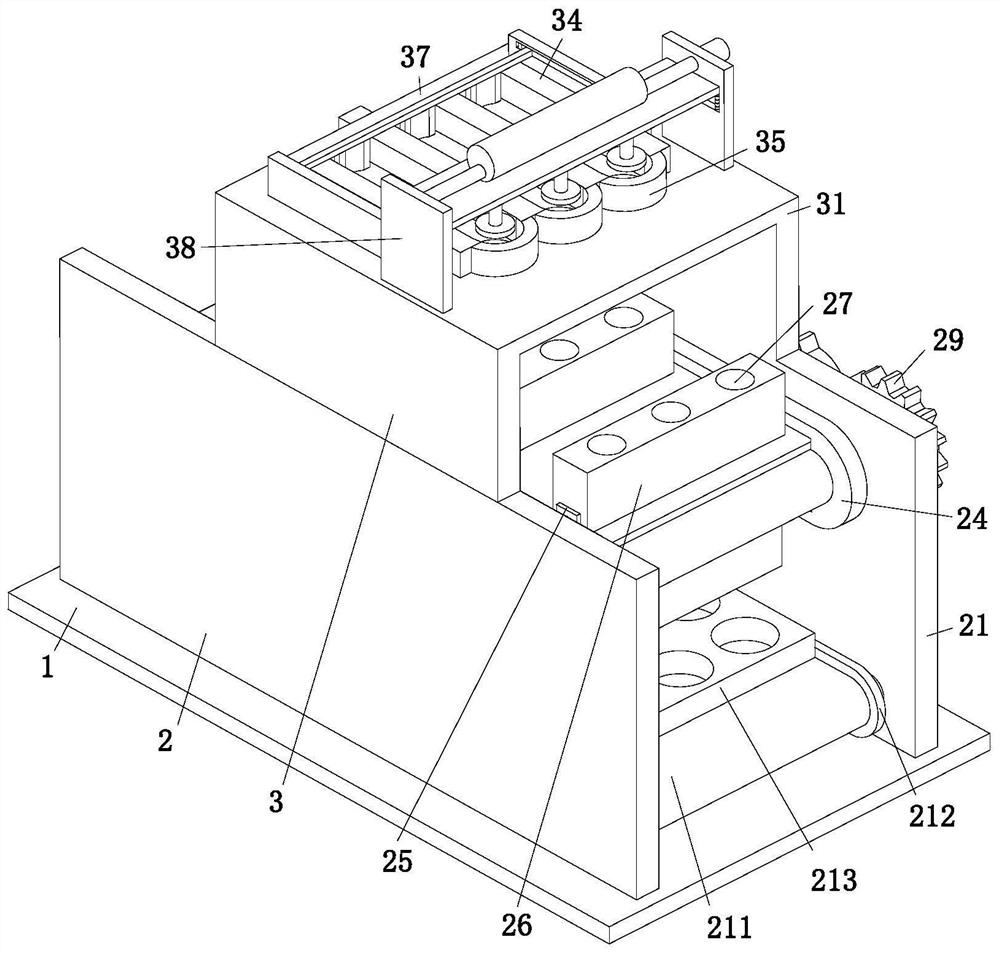

[0033] refer to figure 1 and figure 2 , a vacuum blood collection test tube compound machine, comprising a worktable 1, a fixing device 2 and a moving device 3, the upper end surface of the working table 1 is provided with a fixing device 2, and the fixing device 2 is provided with a moving device 3;

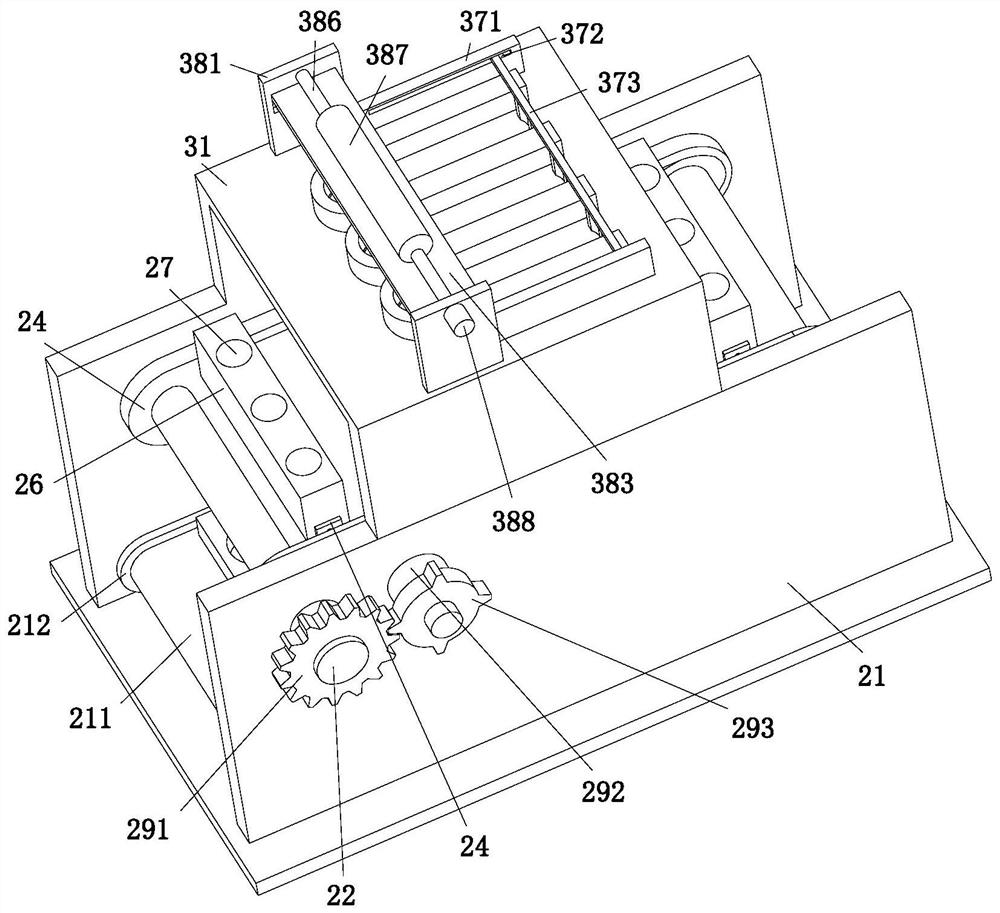

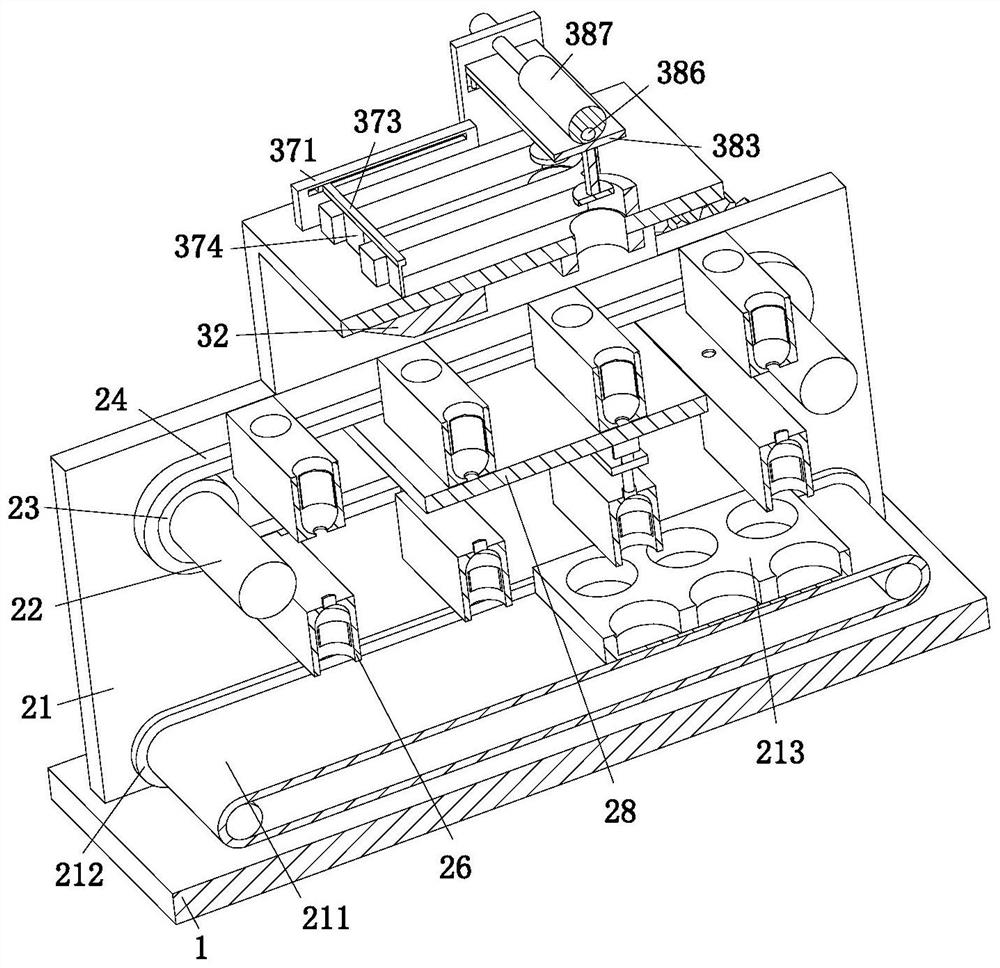

[0034] refer to figure 1 , figure 2 , image 3 and Figure 4, the fixing device 2 includes a fixing plate 21, a rotating shaft 22, a sprocket 23, an annular chain plate 24, a branch chain seat 25, a receiving block 26, a No. 1 circular groove 27, a blanking frame 28 and a turret 29, The upper end of the workbench 1 is symmetrically fixed with fixed plates 21 on both sides of the front and rear sides, and the left and right sides of the position between the two fixed plates 21 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com