LED nano black coating and LED display module

A technology of black coating and LED chips, applied in coating, polyester coating, epoxy resin coating, etc., can solve the problems of LED display color difference and insufficient contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

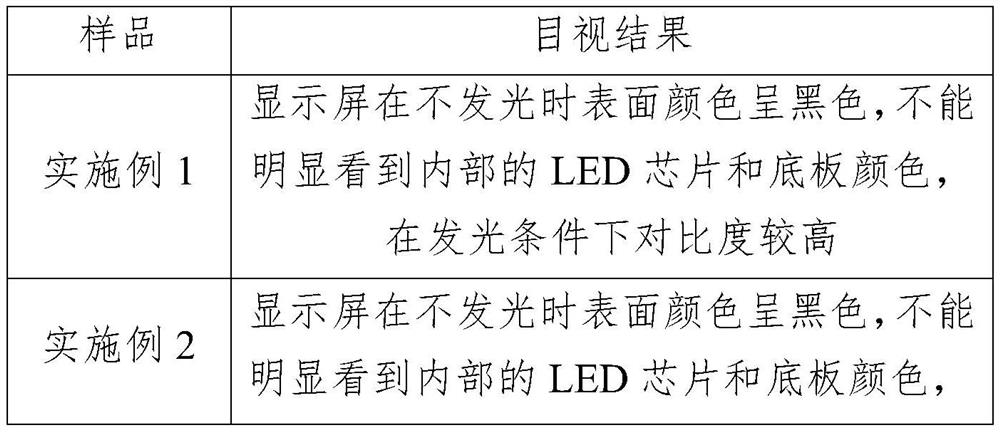

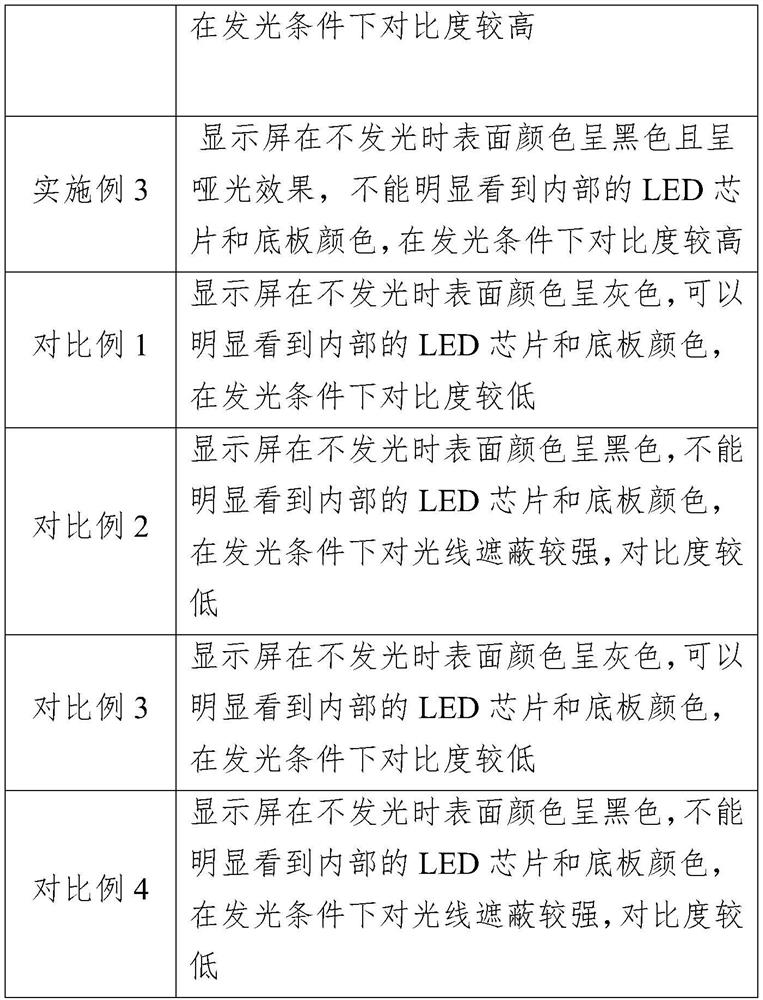

Embodiment 1

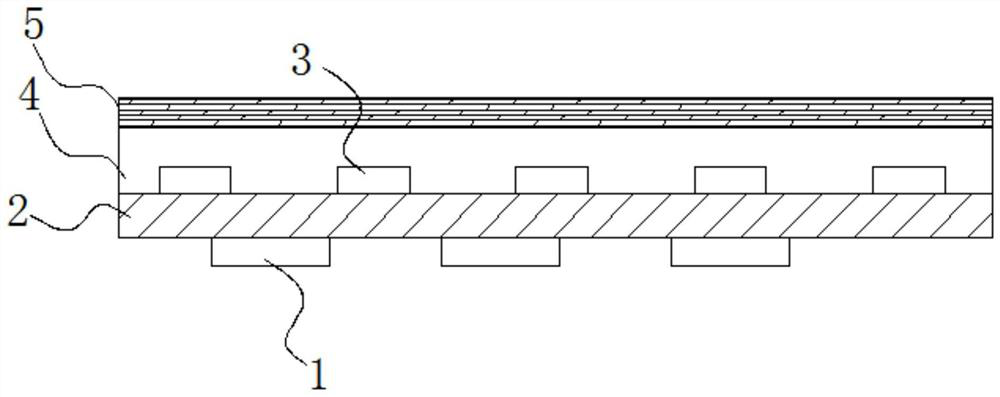

[0056] This embodiment is used to illustrate a LED display module disclosed by the present invention, including a PCB board, LED chips, packaging layer, driver IC and LED nano-black coating, the number of the LED chips is multiple, and the multiple LED chips The LED chip is arranged on the surface of the PCB board, the packaging layer is arranged on the surface of the PCB board and covers the LED chip, and the LED nano-black coating is arranged on a side of the packaging layer away from the PCB board. On the side, the driver IC is arranged on the side of the PCB board away from the LED chip, and the driver IC is electrically connected to the LED chip.

[0057] Wherein, the thickness of the LED nano-black coating is 3um, and the LED nano-black coating includes a resin coating and nano-carbon black dispersed in the resin coating, and the particle size of the nano-carbon black is 30 to 30 μm. 200nm, the number of nano carbon black particles per unit area is 25-900 / um 2 , the lig...

Embodiment 2

[0059] This embodiment is used to illustrate an LED display module disclosed by the present invention, including most of the technical features in Embodiment 1, the difference being:

[0060] The thickness of the LED nano-black coating is 3um, and the LED nano-black coating includes a resin coating and nano-graphene dispersed in the resin coating, and the particle diameter of the nano-graphene is 10-200nm, The number of nano-graphene particles per unit area is 300-900 / um 2 , the light transmittance of the LED nano black coating is 70%.

Embodiment 3

[0062] This embodiment is used to illustrate an LED display module disclosed by the present invention, including most of the technical features in Embodiment 1, the difference being:

[0063] The thickness of the LED nano-black coating is 3um, and the LED nano-black coating includes a resin coating and nano-graphene and nano-silicon dioxide dispersed in the resin coating, and the addition of the nano-silicon dioxide The amount is 1 wt%, the particle size of the nano-graphene is 10-200nm, and the number of nano-graphene particles per unit area is 30-300 / um 2 , the light transmittance of the LED nano black coating is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com