Double-row SMW construction method pile foundation pit supporting structure and construction method thereof

A technology of foundation pit support and engineering piles, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of not being able to quickly find the leakage point construction water stop speed, etc., to achieve rapid water stop, improve the overall strength, The effect of large excavation depths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, so that those skilled in the art can understand the present invention more clearly.

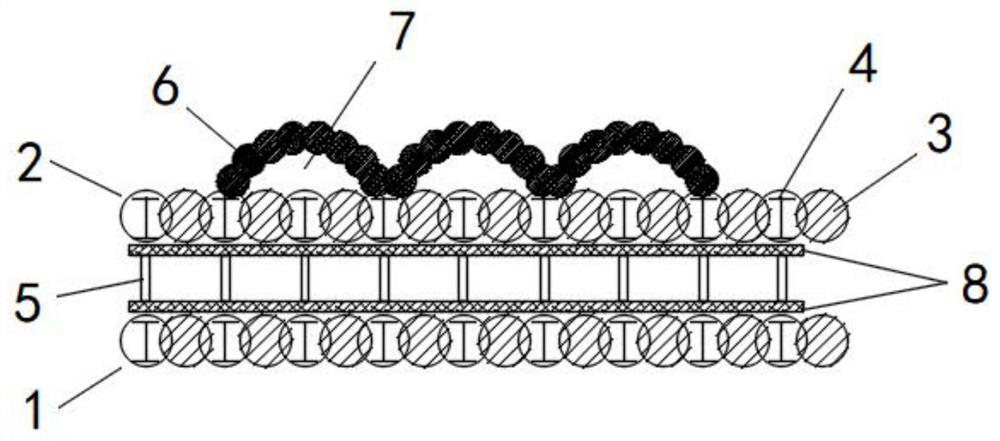

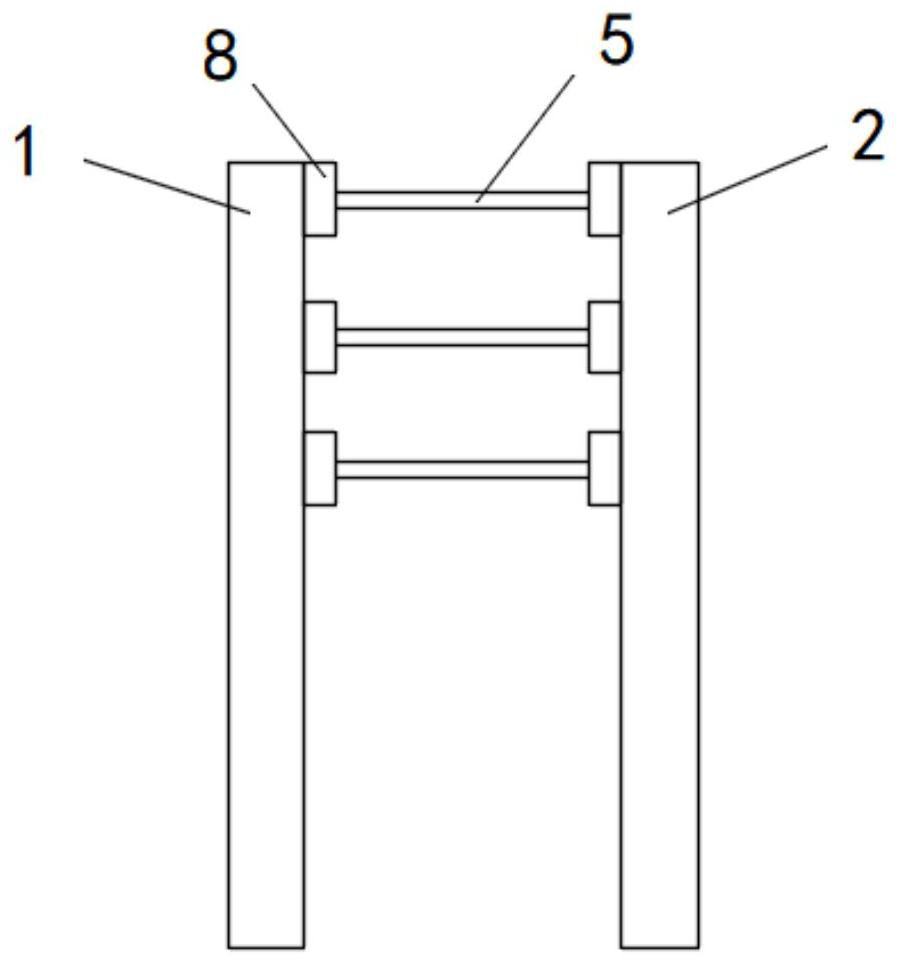

[0027] Such as Figure 1-2 As shown, a double-row SMW construction method pile foundation pit support structure, including the first cement-soil mixing pile support wall 1 arranged near the foundation pit and the second soil mixing pile support wall 2 arranged away from the foundation pit, the above two Each of the cement-soil mixing piles supporting the retaining wall is formed by overlapping and overlapping the first cement-soil mixing piles 3 in sequence. The first cement-soil mixing pile 3 is inserted with H-shaped steel 4, and the above two cement-soil mixing piles support the retaining wall. Connected by several rigid connectors 5, the side of the second soil mixing pile support wall away from the foundation pit is provided with several mixing pile walls, and the mixing pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com