Stoping technical method for controlling hanging wall surrounding rock ground pressure by adopting stope room retention blasted pile

A technology of surrounding rock and mine house, which is applied in the field of back mining where the mining house is used to control the surrounding rock pressure of the upper wall, and it can solve the problems of failure to improve the ground pressure of the stope, low ore collapse efficiency and mining intensity, and easy poverty in the ore production process. to improve the efficiency of ore collapse and mining intensity, ensure the stability of the mine room, and avoid damage caused by stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

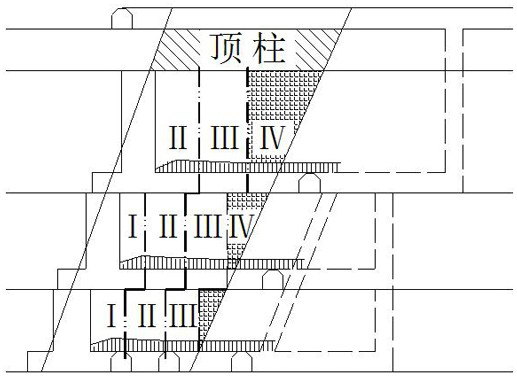

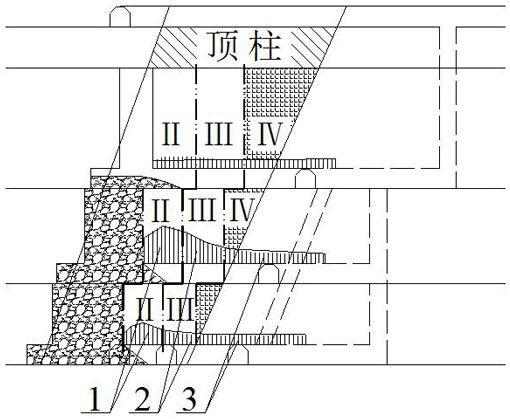

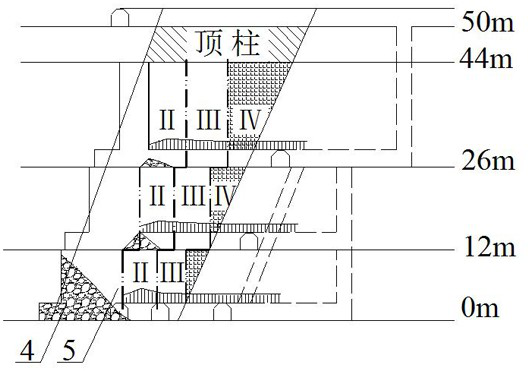

[0026] refer to Figure 1-3 , a method of recovery technology using detent blasting piles in mine houses to control the ground pressure of hanging wall rocks, including a stress-increasing area 1, a stress tending to normal area 2, a stress normal area 3, and stranded blasting piles supporting the hanging wall surrounding rocks 4 , empty space interval 5, according to ore body inclination angle and surrounding rock characteristics, adopt mine house detaining explosive pile 4 to control the surrounding rock ground pressure of the upper wall, to improve the stope ground pressure, reduce the dilution in the process of mining, and also include the following steps:

[0027] S1: Combined blasting, four times of blasting in the back mining of the mine house, and four times of blasting in the middle section of 0m and the subsection of 12m, and the footwall of the 26m subsection in four sections of I, II, III, and IV to control the ore from the hanging wall to be out of the mine lagging...

Embodiment 2

[0032] refer to Figure 1-3 , a method of recovery technology using detent blasting piles in mine houses to control the ground pressure of hanging wall rocks, including a stress-increasing area 1, a stress tending to normal area 2, a stress normal area 3, and stranded blasting piles supporting the hanging wall surrounding rocks 4 , empty space interval 5, according to ore body inclination angle and surrounding rock characteristics, adopt mine house detaining explosive pile 4 to control the surrounding rock ground pressure of the upper wall, to improve the stope ground pressure, reduce the dilution in the process of mining, and also include the following steps:

[0033] S1: Combined blasting, four times of blasting in the back mining of the mine house, and four times of blasting in the middle section of 0m and the subsection of 12m, and the footwall of the 26m subsection in four sections of I, II, III, and IV to control the ore from the hanging wall to be out of the mine lagging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com