Offshore wind turbine generator floating type foundation of grating type structure and construction method

A technology for offshore wind power and wind turbines, which is applied in wind power generation, wind turbines, engines, etc., can solve the problems of large rolling and pitching motions, high risks, and difficult construction and installation, so as to improve the ability to resist wind and waves, Good stability and economy, the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is a detailed description of an embodiment of the present invention.

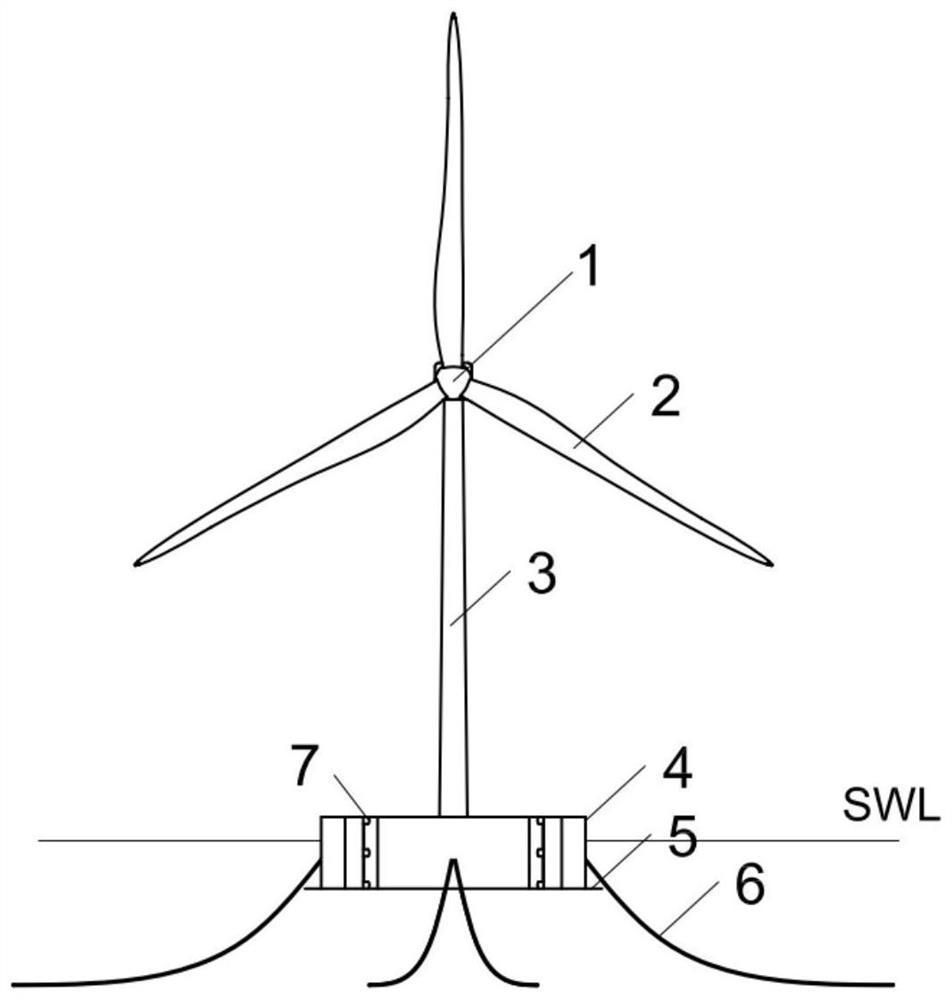

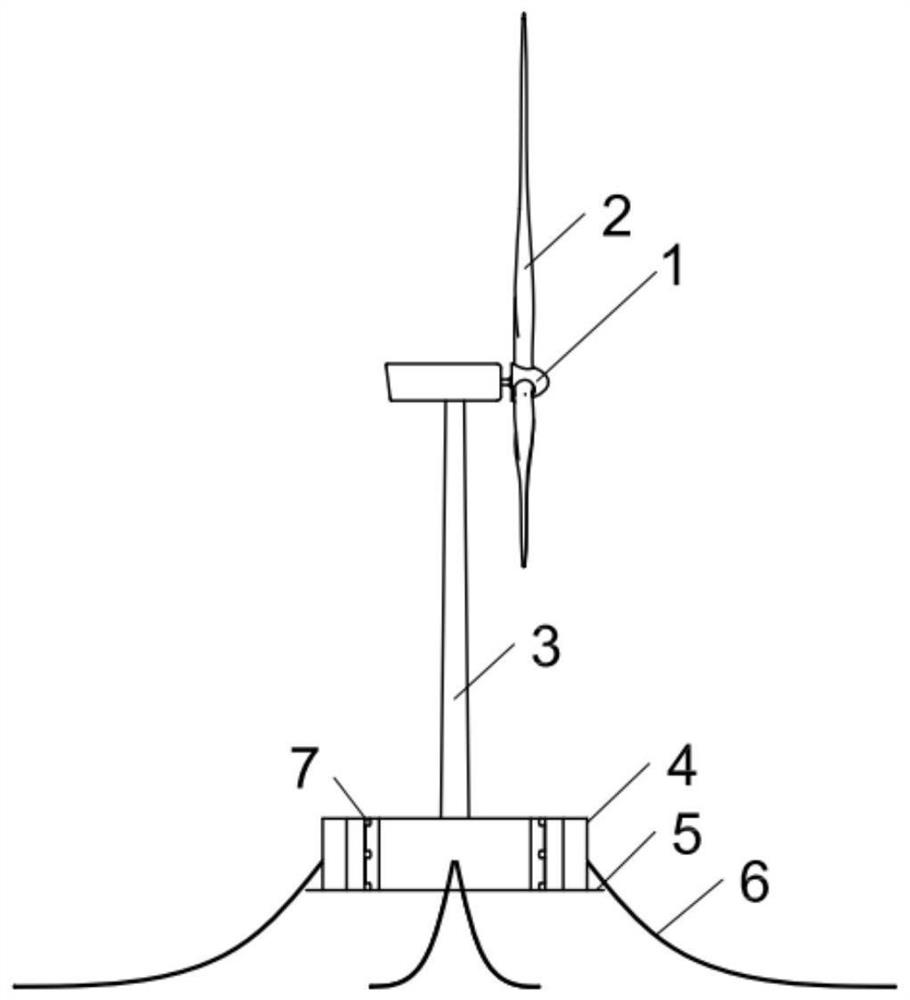

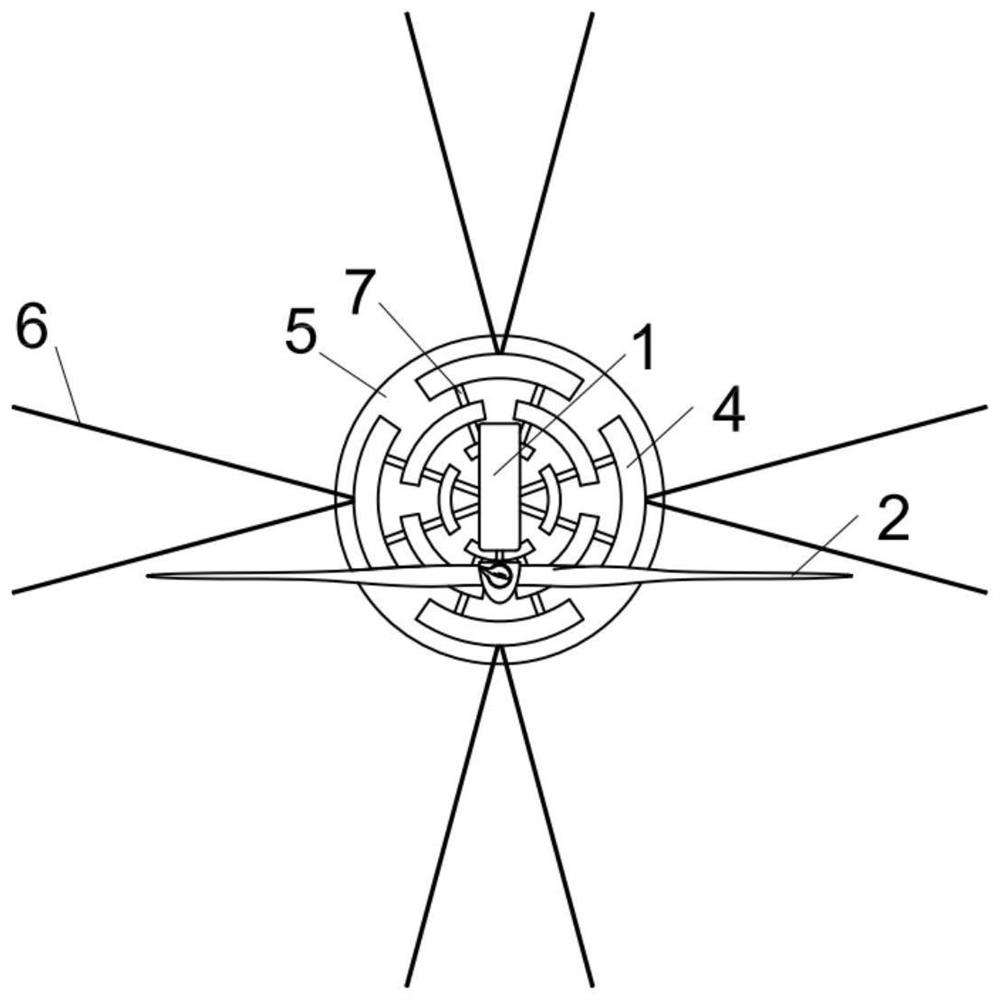

[0033] Such as figure 1 , 4 As shown, a floating foundation for offshore wind turbines with a new grid structure mainly includes: a cylindrical central column 8 , a grid fan ring foundation 4 , a circular water pressure plate 5 and a mooring system 6 . The wind turbine tower 3 is connected to the central column 8 .

[0034] Such as figure 1 As shown, when the structure is in operation, the design waterline SWL is located in the middle and upper part of the grid fan ring foundation 4, so as to ensure that the floating foundation has sufficient freeboard height during operation. The wind turbine nacelle 1 is installed on the upper end of the wind turbine tower 3 , and the wind turbine blades 2 are connected to the wind turbine nacelle 1 .

[0035] Such as Figure 4 As shown, the outer diameter of the central column 8 is consistent with that of the tower 3, so there is no need to arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com