Water drop detection system and method for optical mirror surface and water drop erasing system

A detection system, optical mirror technology, applied in the direction of polarization influence characteristics, etc., can solve the problems of reducing image resolution and recognition effect, reducing resolution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

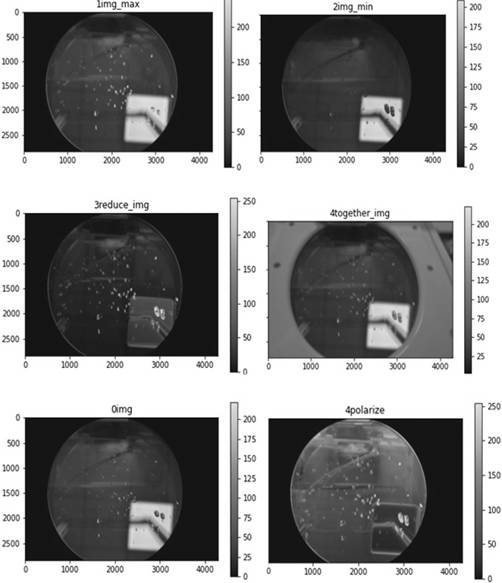

Image

Examples

Embodiment 1

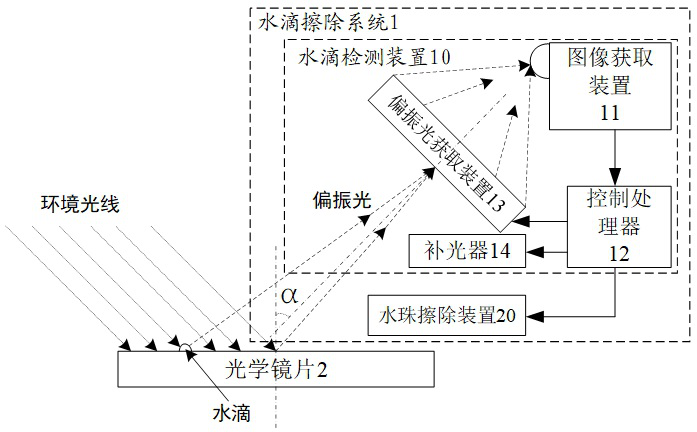

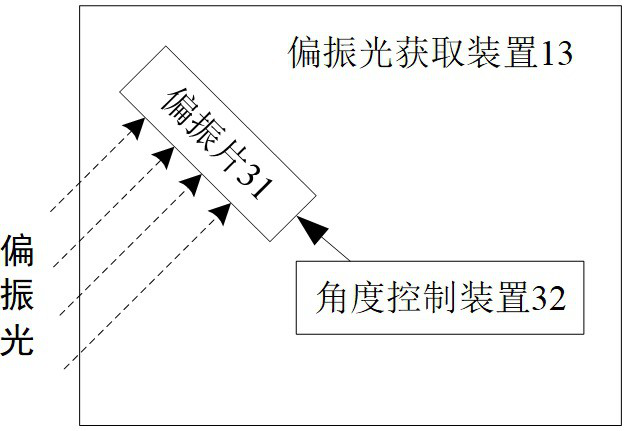

[0052] Please refer to figure 1 , is a schematic diagram of the structural connection of the water drop wiping system in an embodiment of the present application, including the water drop wiping system 1 and the optical lens 2 . The water drop wiping system 1 includes a water drop wiping device 20 and a water drop detection system 10 . The water drop detection system 10 is used to send an erasing command to the water drop erasing device 20 when detecting water droplets on the surface of the optical lens. The water drop erasing device 20 is used for erasing the water droplets on the surface of the optical lens in response to the erasing instruction. The water drop detection system 10 is used to detect water drops attached to the surface of the optical lens. The water drop detection system 10 includes a polarized light acquisition device 13 , an image acquisition device 11 and a control processor 12 . The polarized light obtaining device 13 is used for polarizing and refractin...

Embodiment 2

[0063] Please refer to Figure 4 , is a schematic flow chart of a water drop detection method in an embodiment, the water drop detection method is used to detect water droplets attached to the surface of an optical lens, including:

[0064] Step 100, acquiring polarized light.

[0065] The reflected light on the surface of the optical lens is sequentially polarized and refracted according to a preset polarization angle sequence, so as to obtain polarized light of at least one polarization angle.

[0066] Since most of the equipment for erasing water droplets adhered to the lens are manually started and graded, and some equipment for erasing water droplets adhered to the lens that can be automatically controlled does not directly measure the amount and degree of influence of water droplets adhered to the lens. Instead, it is controlled by other easily obtained information such as rainfall, which may cause the lens to adhere to water droplets. Of course, there are also direct i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com