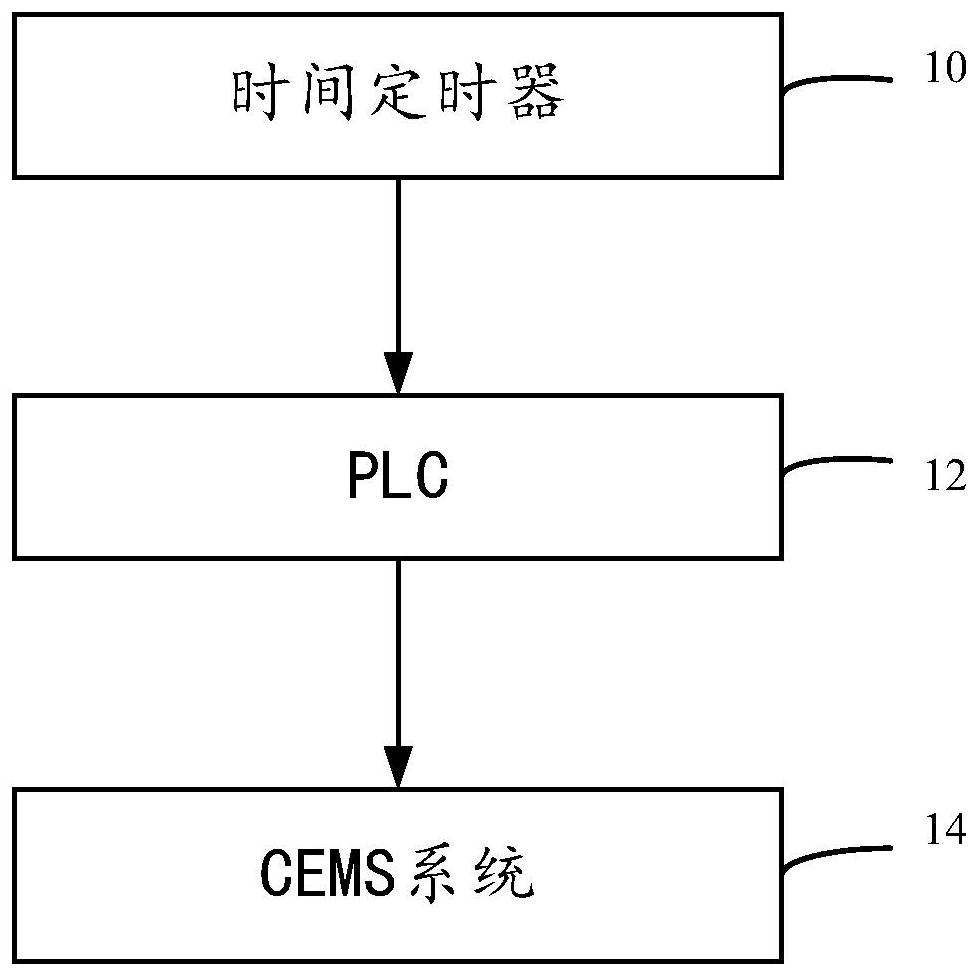

Device and method for controlling blowing and automatic calibration of CEMS (Continuous Emission Monitoring System) by timer

A time timer and automatic calibration technology, which is applied in general control systems, control/regulation systems, program control, etc., can solve problems such as inaccurate timing and environmental pollution, achieve increased stability, avoid environmental pollution incidents, and monitor stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

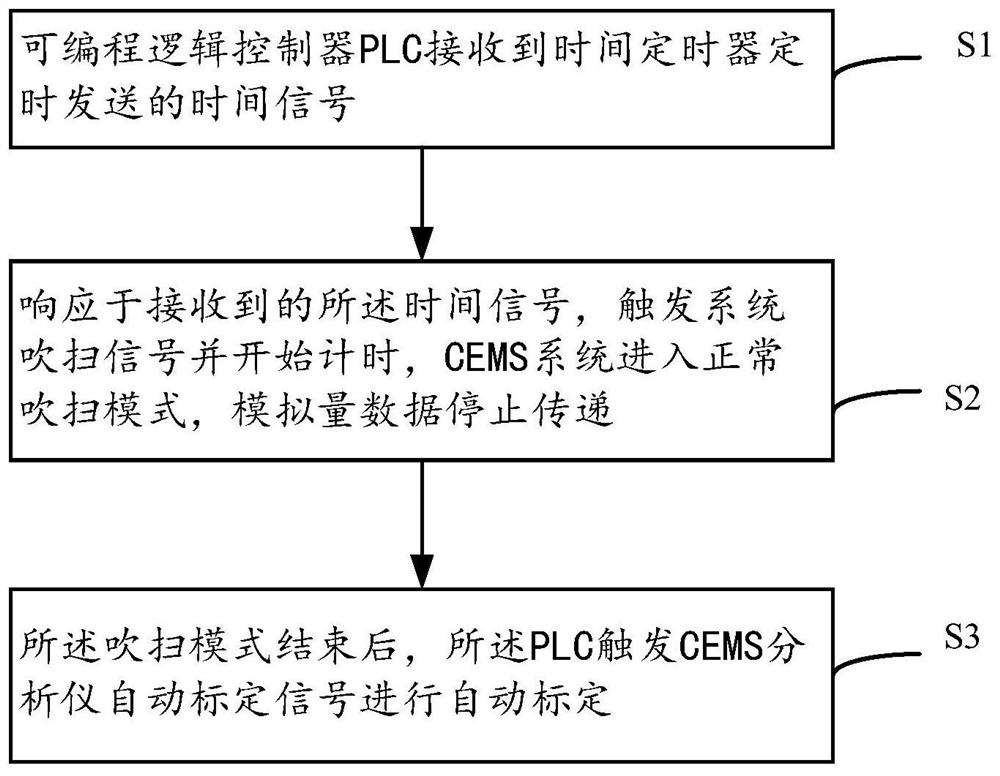

[0036] Set the time timer to send out a DO1 signal of type 3S pulse at 0 minutes per hour, use the 24V power supply to provide power for the automatic calibration signal of the CEMS analyzer, and redesign the logic in the PLC.

[0037] System purge:

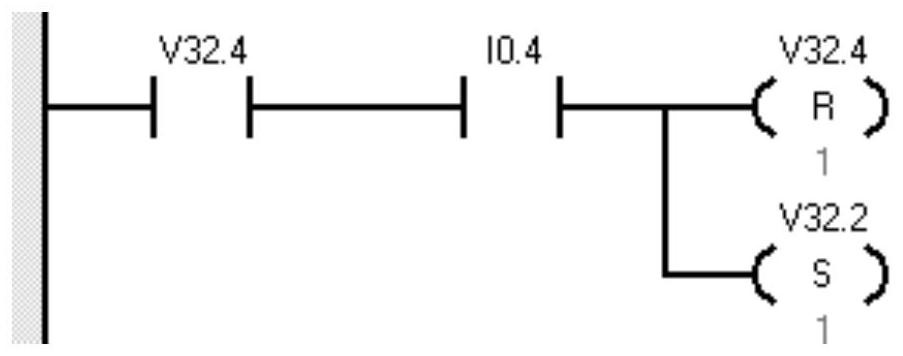

[0038] After the PLC receives the DO1 signal (I0.4), it sets the purge mode start command V32.2 to 1, and resets the command V32.4 to control all systems to resume normal operation to 0, such as image 3 As shown, the system enters the normal purge mode at this time and starts to purge. In the figure, R in the coil indicates that the output is 0 after it is turned on, and S in the coil indicates that the output is 1 after it is turned on.

[0039] When V32.2 is set to 1, such as Figure 4 As shown, the time relay T111 starts timing for 180 seconds, and the analog data stops passing through M10.1, such as Figure 6 As shown, when V32.2 is reset to 0, the delay is 420 seconds, and the data transmission returns to normal.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com