Powder metallurgy refractory multi-principal element high-entropy alloy and its preparation method

A high-entropy alloy and powder metallurgy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problem of limiting the application and promotion of refractory multi-principal element high-entropy alloy materials, and large-scale mass production of refractory multi-principal element high-entropy alloys Difficulty, high cost and other issues, to achieve the effect of easy safety risk control, fine microstructure, and conducive to diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of powder metallurgy refractory multi-principal high-entropy alloy specifically includes the following steps:

[0054] Step S1: pass the refractory metal element through a 300-mesh sieve; the powder is mixed by a multi-component powder mixing method to obtain a mixture;

[0055] The mixture is at least four elements in Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W;

[0056] The atomic percentage of each element in the mixture is 5%-35%; the total percentage is 100%;

[0057] Step S2: press forming to obtain a pressed blank;

[0058] Step S3: vacuum high-temperature solid-phase sintering to obtain a sintered block.

[0059] The present invention uses the multi-component powder mixing method to process the raw material powder.

[0060] This method uses element powders with higher purity for mixing, which is different from high-energy ball milling mechanical alloying in that this method only mixes multi-element powders without grinding them. It has the followi...

Embodiment

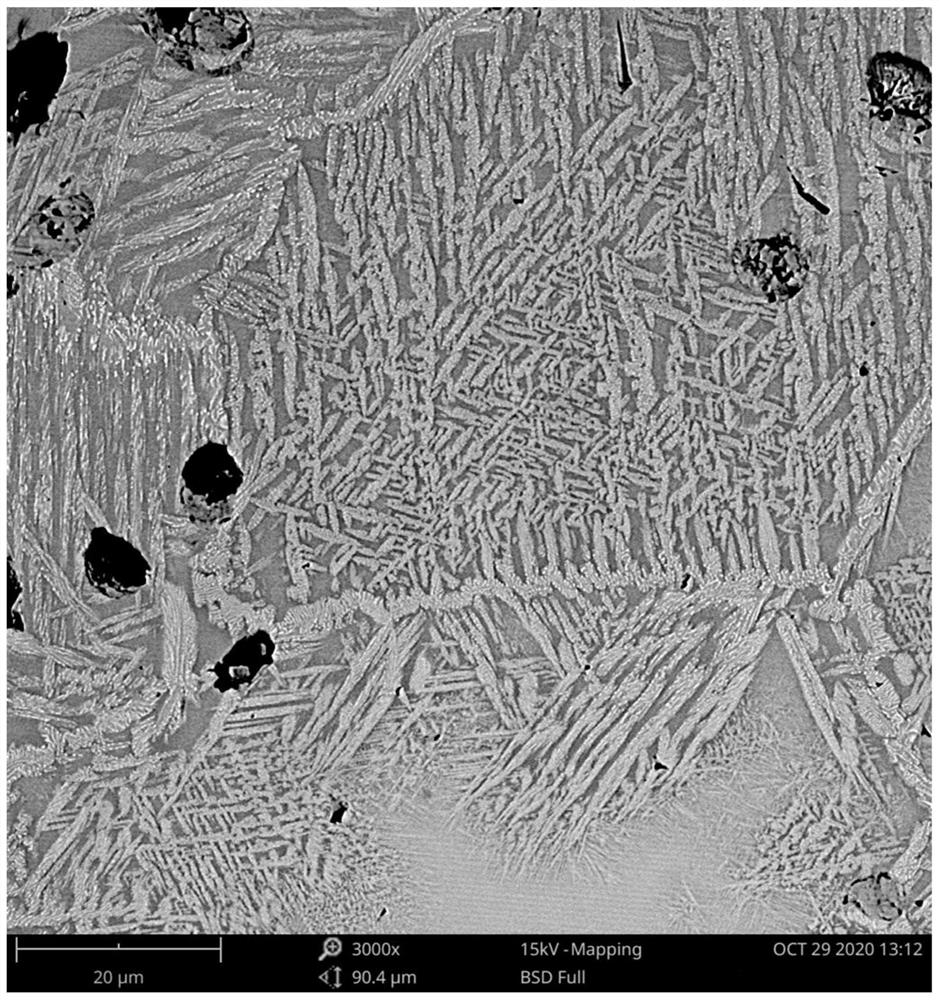

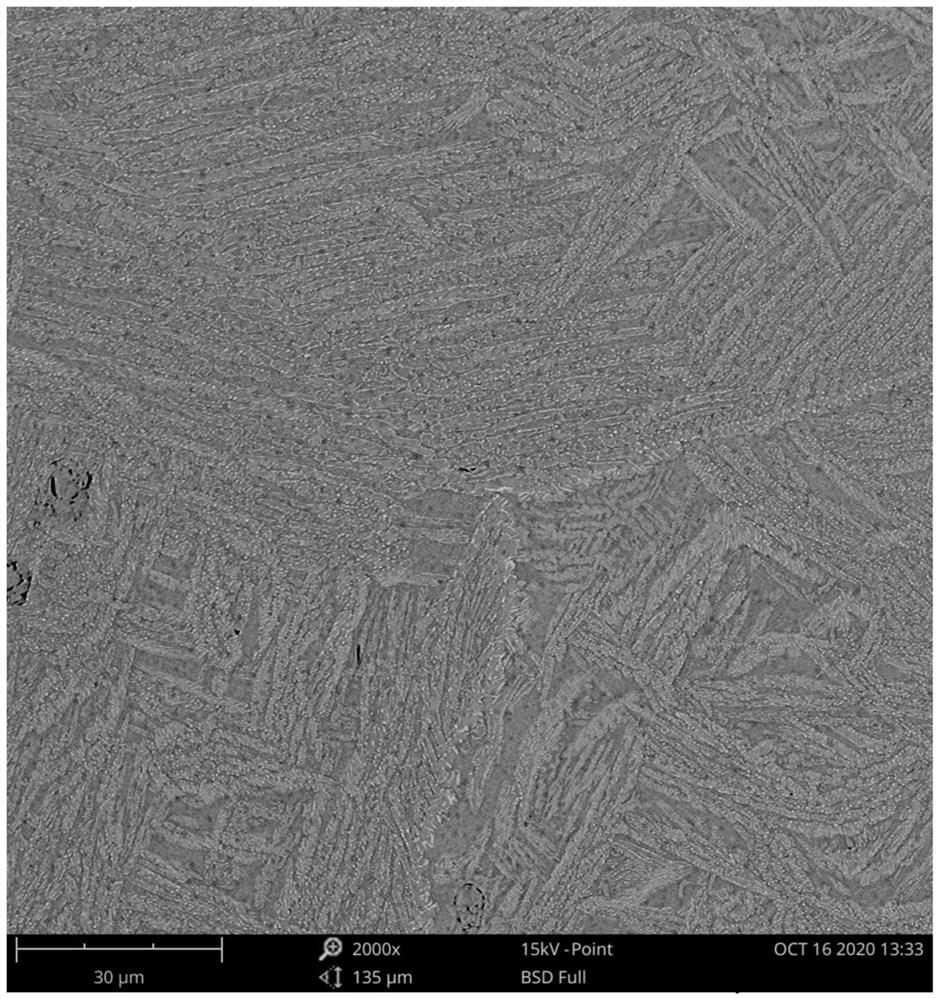

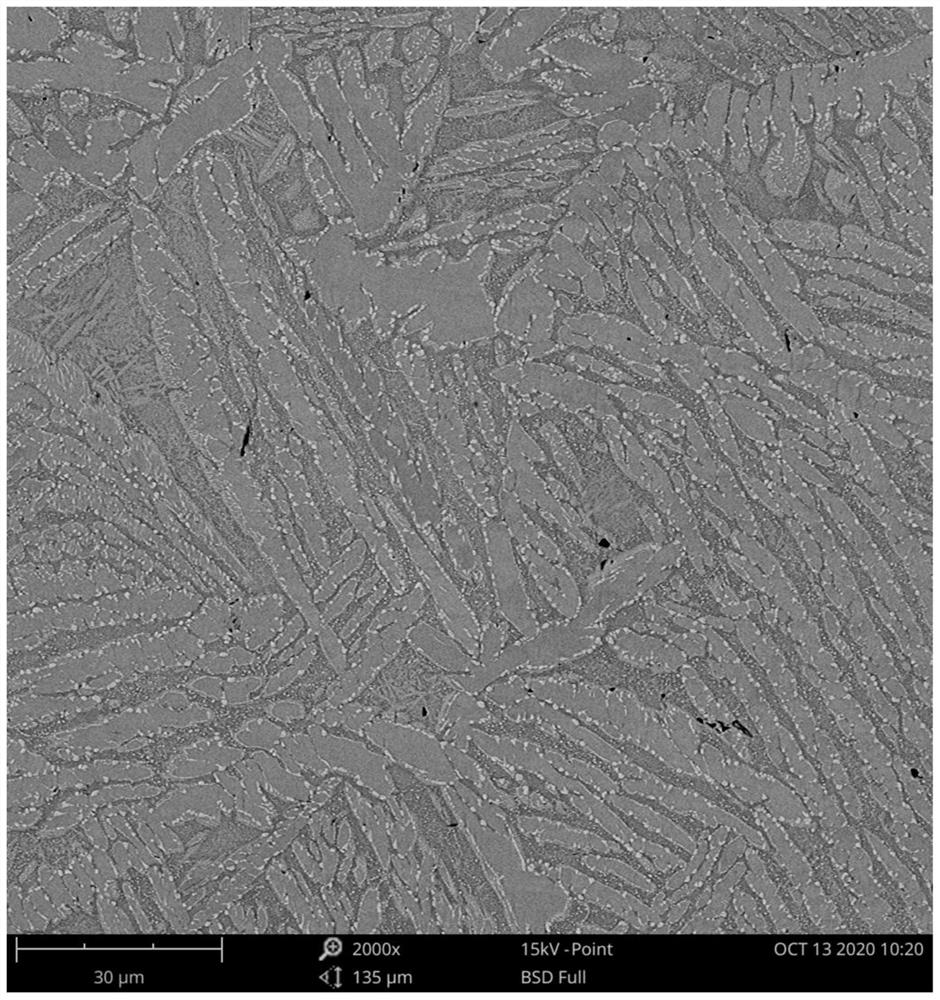

[0093]Take a refractory multi-principal high-entropy alloy containing Ti, Zr, Hf and Ta as an example, in which the atomic percentages of Ti, Zr, Hf and Ta are 28.33%, 28.33%, 28.33% and 15.01%, respectively. According to the data, the melting point of the alloy is T m About 1850℃, by the sintering temperature T s =α·T m Calculate, its sintering temperature T s The range is 1387.5°C-1585.7°C. In order to facilitate the setting of sintering process parameters, 1400°C and 1500°C within this range are taken as the sintering temperature for testing. The sintering process parameters consisting of different sintering temperatures and holding times were set in the experiment, which were 1500℃×60 minutes, 1500℃×180 minutes, 1500℃×300 minutes, 1500℃×420 minutes, 1400℃×300 minutes, 1300℃ ×300 minutes, 1800°C ×300 minutes.

[0094] 1. Preparation

[0095] Step S1: multi-component powder mixing;

[0096] Weigh commercially available Ti powder, Zr powder, Hf powder and Ta powder with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com