Vibration reduction type shield duct piece joint structure and shield duct piece vibration reduction method

A technology of shield segment and joint structure, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., and can solve the problems of affecting the limit of train operation, high replacement cost, and large construction impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

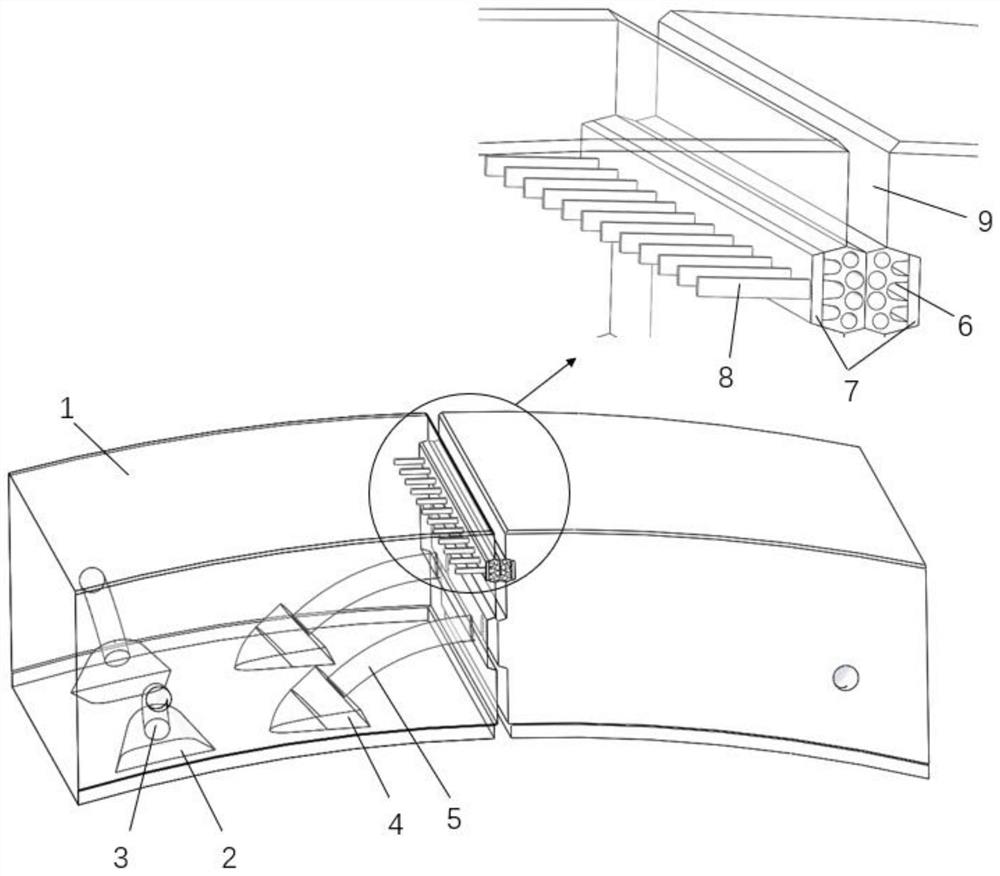

[0039] This implementation example is a vibration-damping bolt kit for a subway segment. Segment 1 has an outer diameter of 6.7m, an inner diameter of 5.9m, and a thickness of 350mm.

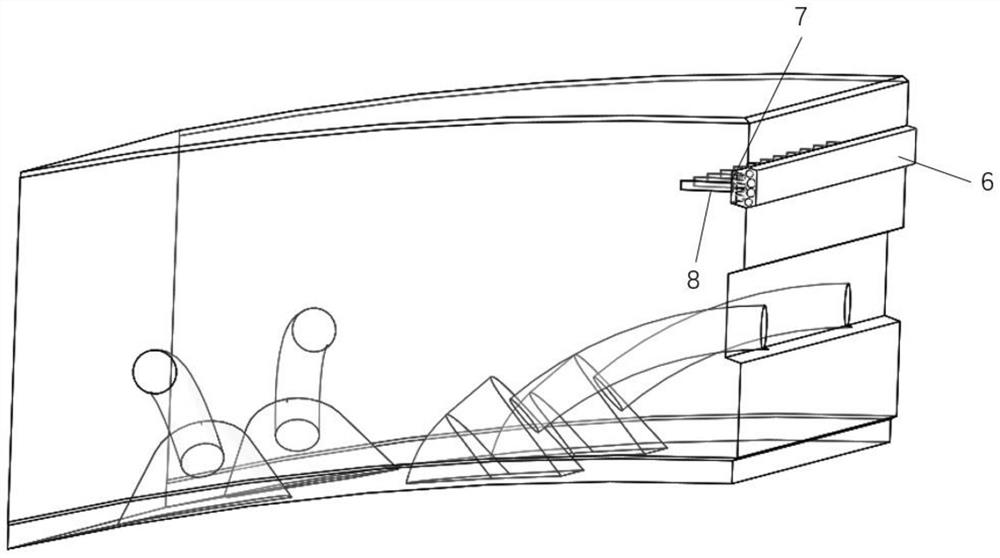

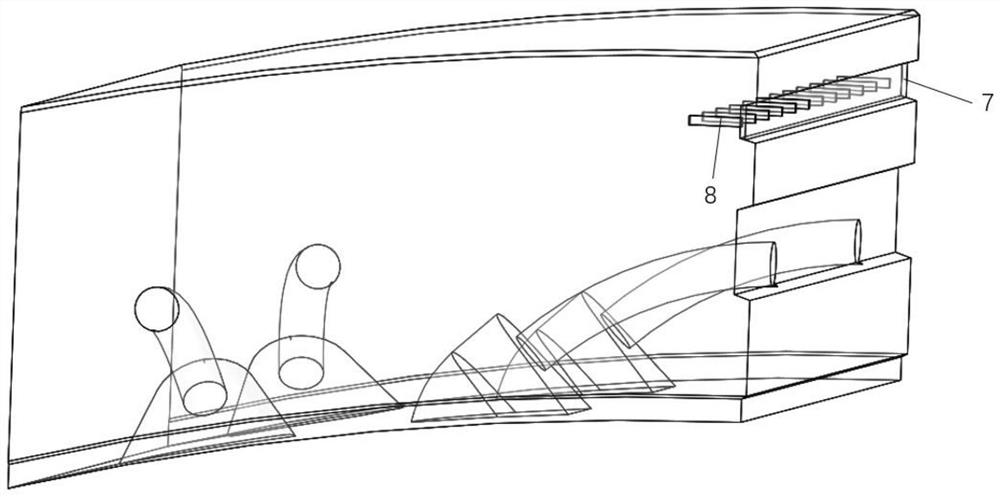

[0040] Such as figure 1 Shown is a schematic diagram of the vibration-type segment joint structure of the present invention, a vibration-damping shield segment joint structure, the main material of the segment is a reinforced concrete structure, the concrete label is generally C50, and its elastic modulus is 3.45× 10 4 MPa, Poisson's ratio is 0.2, density is 2420kg / m 3 .

[0041] The annular seam bolt hole 3 and the longitudinal seam bolt hole 5 are located inside the segment 1, and are arc-shaped cavity structures with a hole diameter of 42 mm. The wall thickness is 3mm, the material is high-strength plastic, and the outside is in direct contact with the concrete inside the segment.

[0042] The sealing gasket 6 is located at the joint of two adjacent segments, and has the function of seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com