Metal product thread detection device

A detection device and thread technology, which is applied to measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve problems such as errors in detection results, incorrect counting, and inability to detect whether the size of the thread is correct, so as to achieve convenient replacement and diversified functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

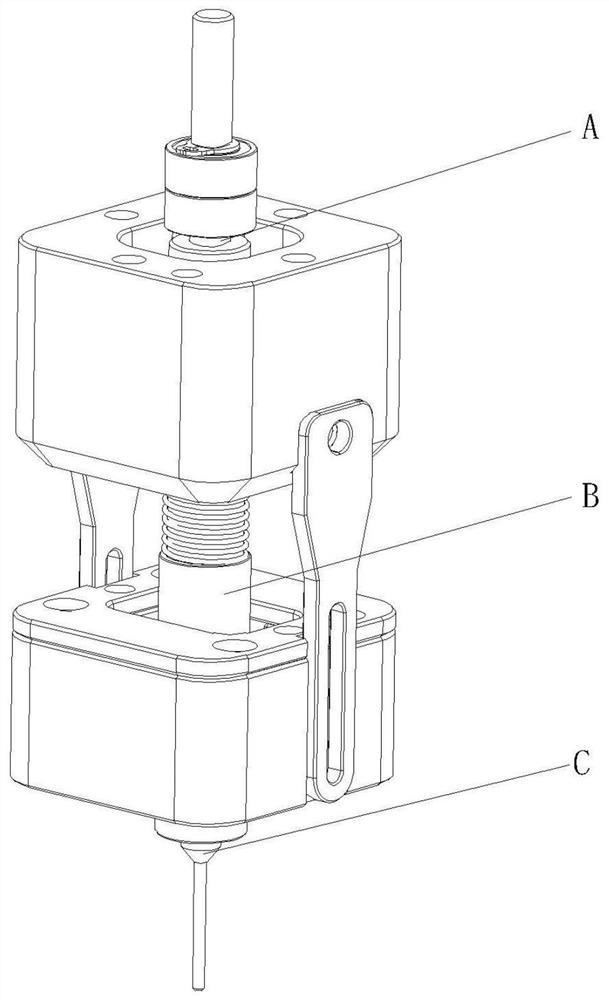

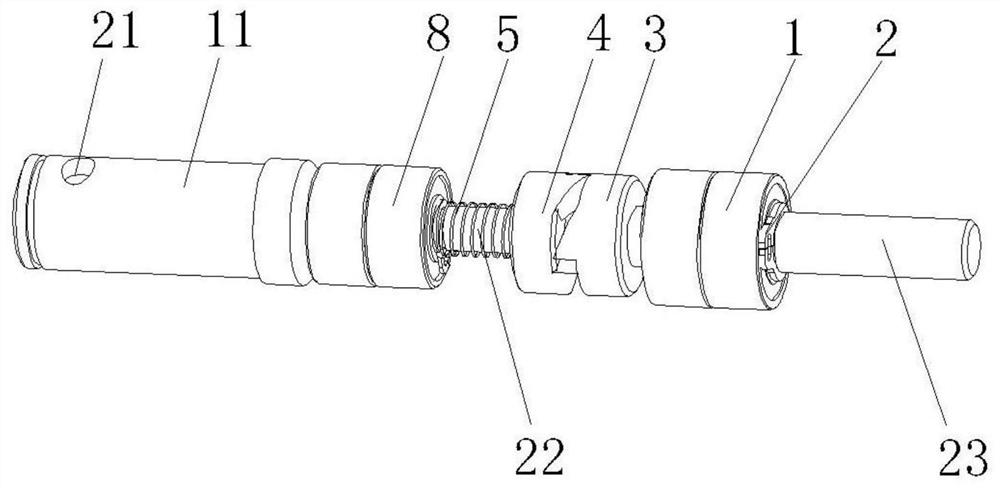

[0032] Such as Figure 1-Figure 7 The shown metal product thread detection device includes a stuck protection mechanism A, an installation mechanism B and a detection mechanism C. The stuck protection mechanism includes two first stuck protection parts 3 that can enter a combined or separated state And the second jamming protection part 4, the first shaft 23 is formed on the first jamming protection part, and the first shaft is connected to the first bearing 1; the installation mechanism includes a screw gauge installation sleeve 11, and the The screw gauge installation sleeve includes a sleeve main body 26, on which a second rotating shaft 22 is formed, and a second bearing 8 is arranged on the second rotating shaft, and a second bearing 8 is arranged between the second bearing and the second jamming protection part. The first elastic reset member 5; the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com