Dragging torque detection equipment for disc brake caliper

A technology of drag torque and detection equipment, applied in measuring devices, torque measurement, power measurement, etc., can solve the problem of difficult brake caliper optimization and improvement, lack of, and inability to accurately measure the brake pad and brake disc drag on a single side. Hysteresis value and other issues, to achieve the effect of reducing the number of test tooling and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

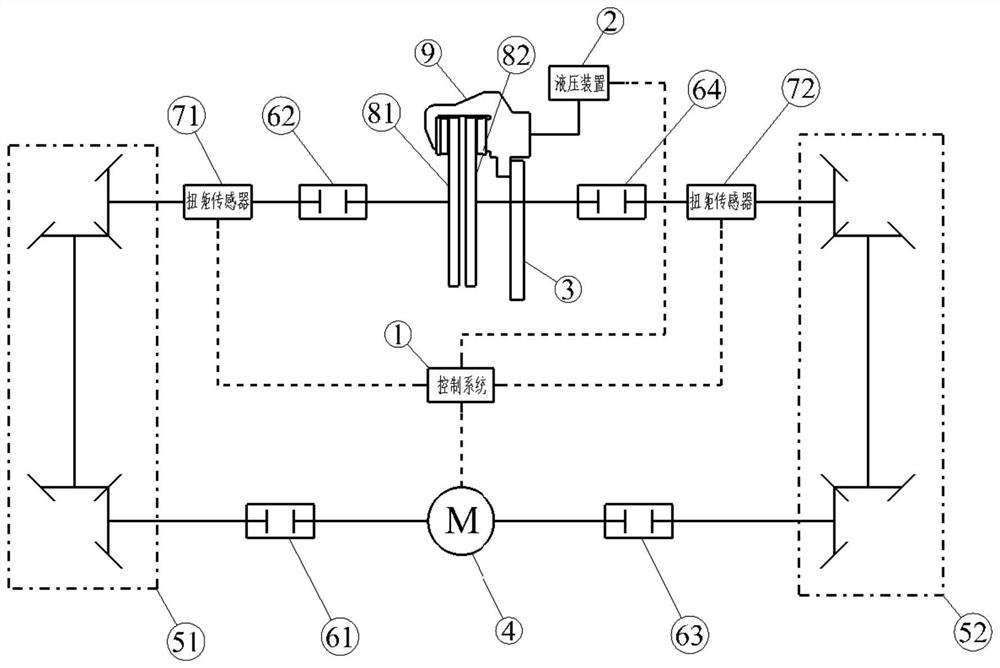

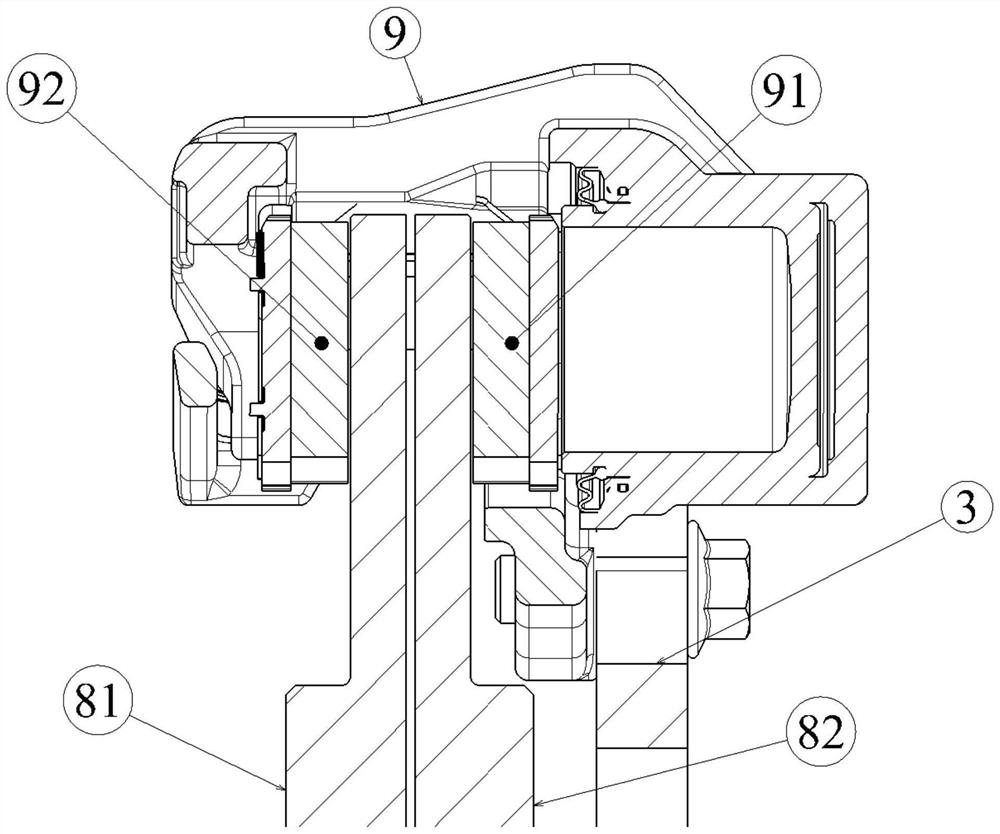

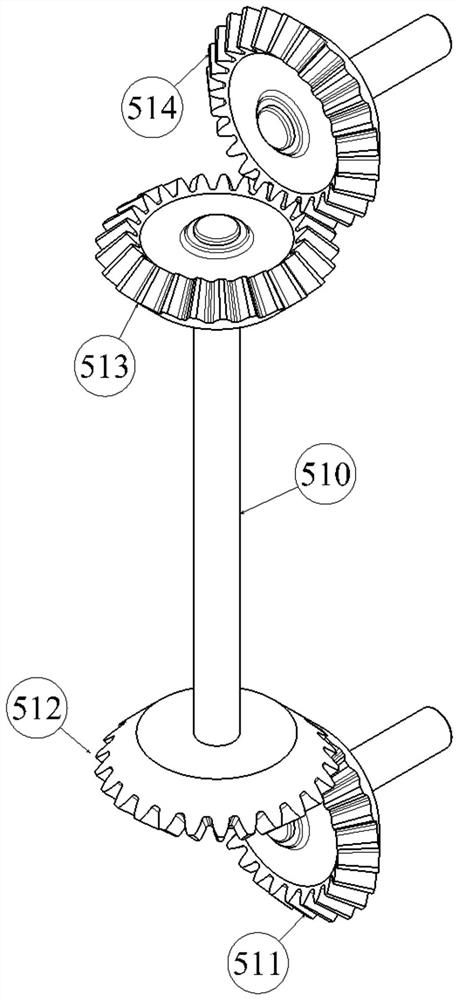

[0030] The equipment includes a brake 9 , a driving device 4 , a transmission mechanism 51 , 52 , a shaft coupling, a torque sensor and simulated brake discs 81 , 82 .

[0031] like figure 1 As shown, the driving device 1 is a biaxial output motor, and the output shafts at both ends of the biaxial output motor are respectively connected to a coupling 61 and a coupling 63; the coupling 61 is connected to the transmission mechanism 51, the torque sensor 71, the coupling After 62, it is coaxially connected with the simulated brake disc 81; after the shaft coupling 63 is connected with the transmission mechanism 52, the torque sensor 72, and the shaft coupling 64, it is coaxially connected with the simulated brake disc 82.

[0032] The torque sensor 72 can measure the torque value transmitted by the simulated brake disc 82 to the shaft, and the torque sensor 71 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com