Automatic continuous measurement method for steam-water sampling hydrogen conductivity

A technology of hydrogen conductivity and measurement method, which is applied in the direction of material resistance, etc., can solve the problems of abnormal data that cannot be replaced in time for operation and maintenance, cannot guarantee the continuity of monitoring, and occupies a small space, so as to achieve automatic continuous measurement, avoid interruption and The abnormality of monitoring data and the effect of simple and reasonable overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

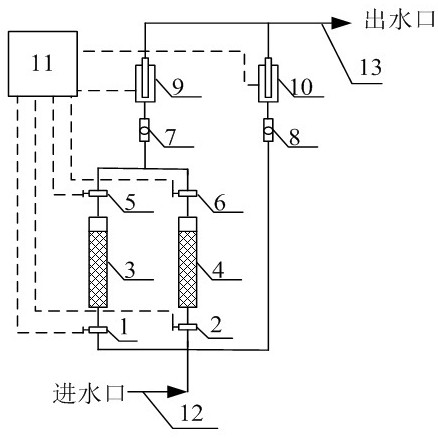

[0018] refer to figure 1 , the present embodiment steam water sampling hydrogen conductivity automatic continuous measurement device comprises a first valve 1, a second valve 2, a first cation exchange resin column 3, a second cation exchange resin column 4, a third valve 5, a fourth valve 6, A first flow meter 7 , a second flow meter 8 , a first conductivity tester 9 , a second conductivity tester 10 , a control system 11 , a water sample inlet 12 and a water sample outlet 13 . The water inlet 12 of the water sample is respectively connected with the inlet of the first valve 1, the second valve 2, and the second flowmeter 8; the first valve 1 is connected with the inlet of the first cation exchange resin column 3, and the second valve 2 is connected with the inlet of the second cation exchange resin. The inlet of the resin column 4 is connected; the outlet of the first cation exchange resin column 3 is connected with the third valve 5, the outlet of the second cation exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com