Quick loading method for structural finite element

A finite element and fast technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of difficult to accurately capture the loading position, the accuracy of the results cannot be guaranteed, time-consuming and labor-intensive, etc., to achieve fast and efficient reuse, Effects that simplify preprocessing and are easy to reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

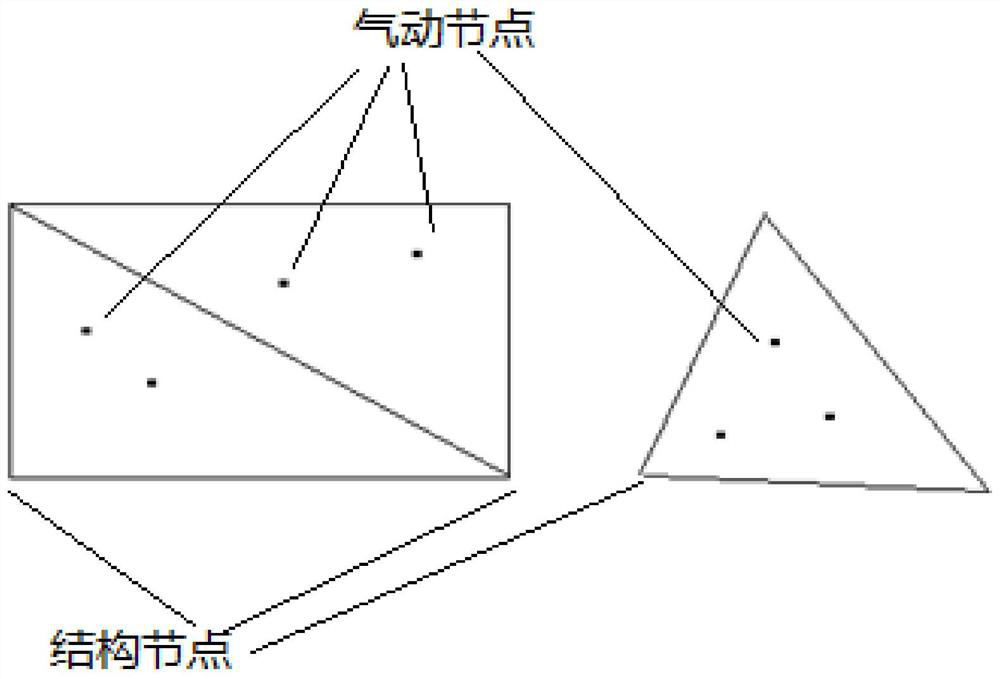

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] figure 1 , figure 2 with image 3 A structural finite element rapid loading method is shown, select the original load of the structure, and classify the original load: divided into distributed surface load, concentrated force and discrete point force;

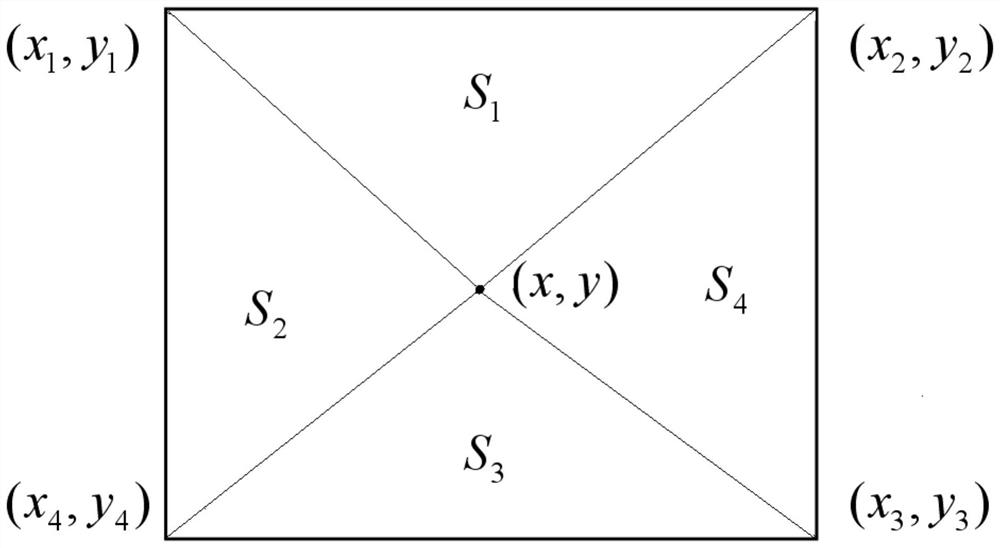

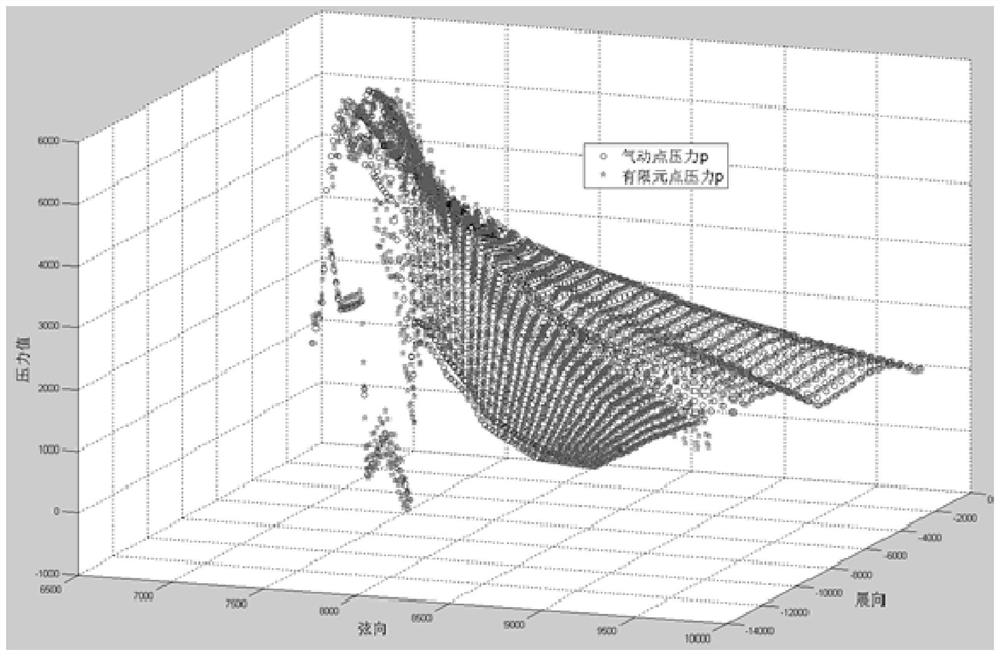

[0018] For the surface loading, the cubic spline interpolation and the polynomial algorithm above the second degree are directly used to perform one-dimensional mapping from two directions in the surface (usually the x direction and the y direction), and then perform coupling and generate a formatted card Force card to Taking the mapping of distributed aerodynamic loads to finite element loads as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com