Heat dissipation structure of APF device

A technology of heat dissipation structure and cabinet, which is applied in the modification of power electronics, structural components of electrical equipment, cooling/ventilation/heating renovation, etc. Easy to manufacture and assemble, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

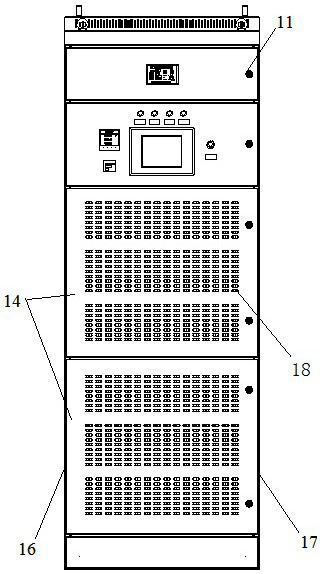

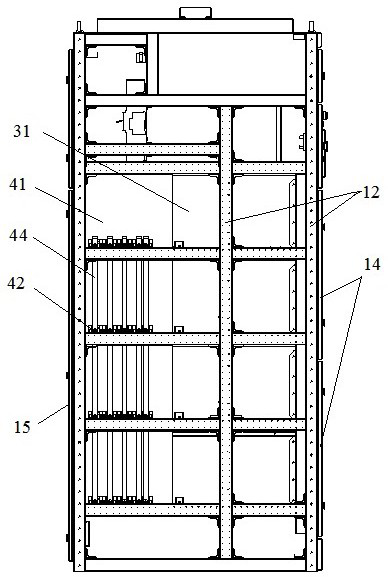

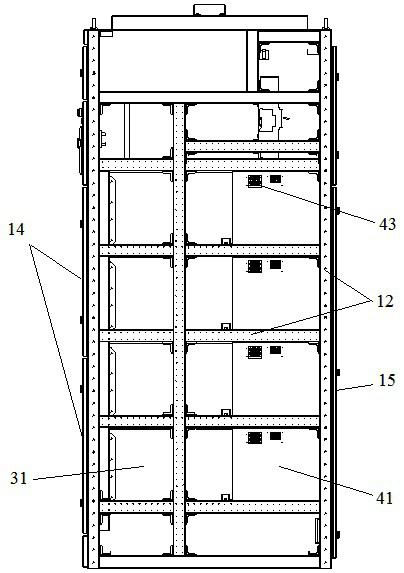

[0047] The heat dissipation structure of the APF device is a direct row type air distribution channel heat dissipation structure, such as figure 1 , figure 2 , image 3 and Figure 4 , including a cabinet body 11, the cabinet body 11 includes a frame 12 and a cover plate, and the cover plate includes a front door panel 14, a rear door panel 15, a left side panel 16 and a right side panel 17. The cabinet body 11 is provided with module partitions 21 , and each module partition board 21 is arranged at intervals up and down, and a plurality of module installation cavities are separated in the cabinet body 11 ; an APF module 31 is installed on each module partition board 21 . The module spacer 21 on which the APF module 31 is mounted forms a module mounting plate corresponding to the APF module 31 .

[0048] Specifically, such as Figure 5 , There are four APF modules 31 , and each APF module 31 is arranged in the cabinet body 11 along the vertical direction. Each APF module...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the air duct gusset 47 corresponding to a certain APF module 31 is buckled downwards on the top of the module partition 21 used to install the APF module 31. In this embodiment, the air duct gusset 47 corresponding to a certain APF module 31 is buckled upwards on the bottom surface of the module partition 21 above the APF module 31, or buckled upwards on the uppermost APF module 31 and the bottom surface of the partition between the uppermost APF module 31 and the cooling chamber above.

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that, in Embodiment 1, the cross section of the air duct gusset 47 is U-shaped; while in this embodiment, the cross section of the air duct gusset 47 is semicircular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com