Micro-plastic separation device

A separation device and technology for microplastics, which are applied in filtration separation, solid separation, separation methods, etc., can solve the problems of small size of microplastics, waste of manpower, and difficult industrial control, and achieve the effect of improving separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

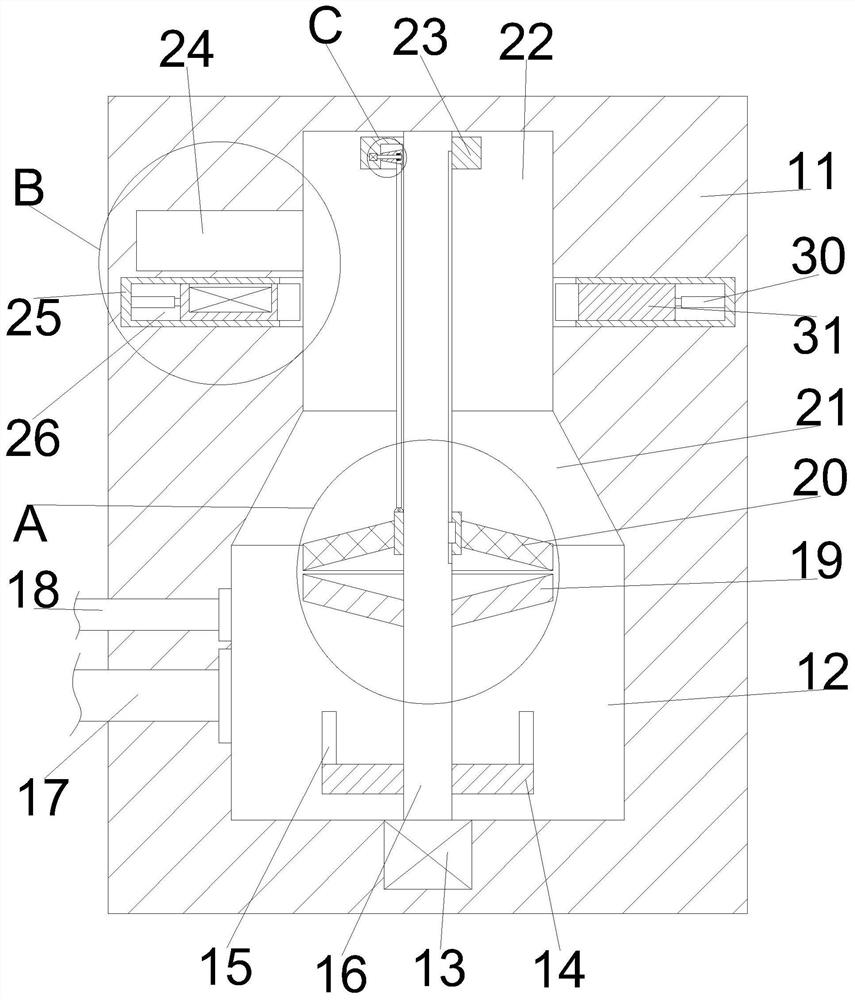

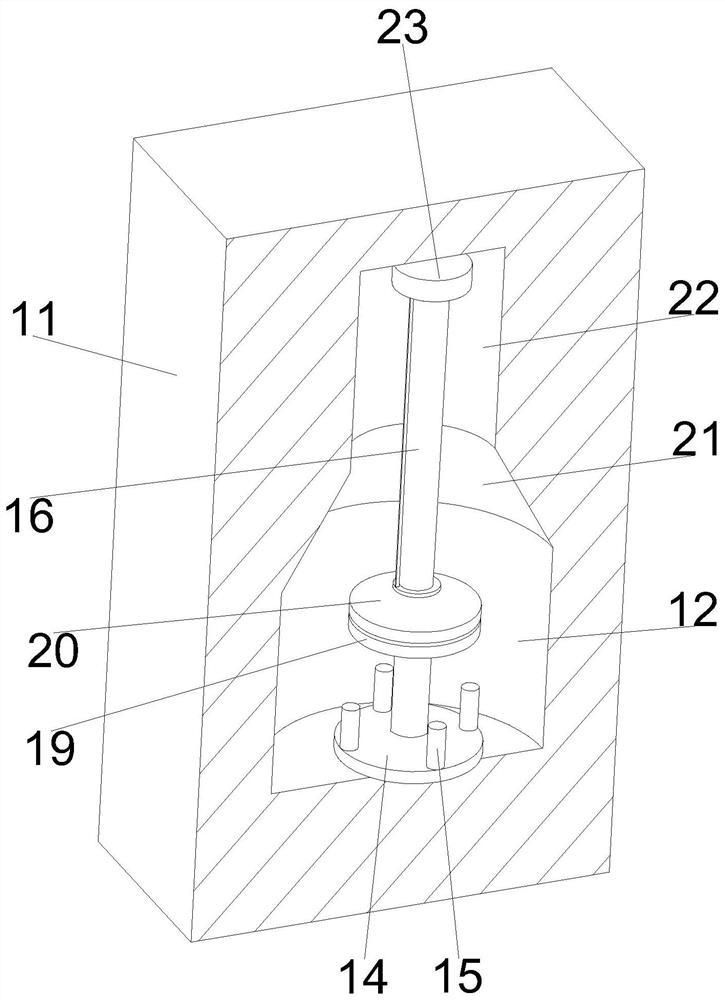

[0032] Specific embodiment one: please refer to Figure 1-6 A microplastic separation device, comprising a main body 11, a water inlet chamber 12, a conical chamber 21, a separation chamber 22, a conical filter plate 20, a traction block 23 and a pull cord 28;

[0033] The water inlet chamber 12, the tapered chamber 21 and the separation chamber 22 are all arranged in the main body 11, and the water inlet chamber 12, the tapered chamber 21 and the separation chamber 22 are arranged sequentially from top to bottom, and the water inlet chamber 12, the tapered chamber 21 and the The separation chambers 22 communicate with each other;

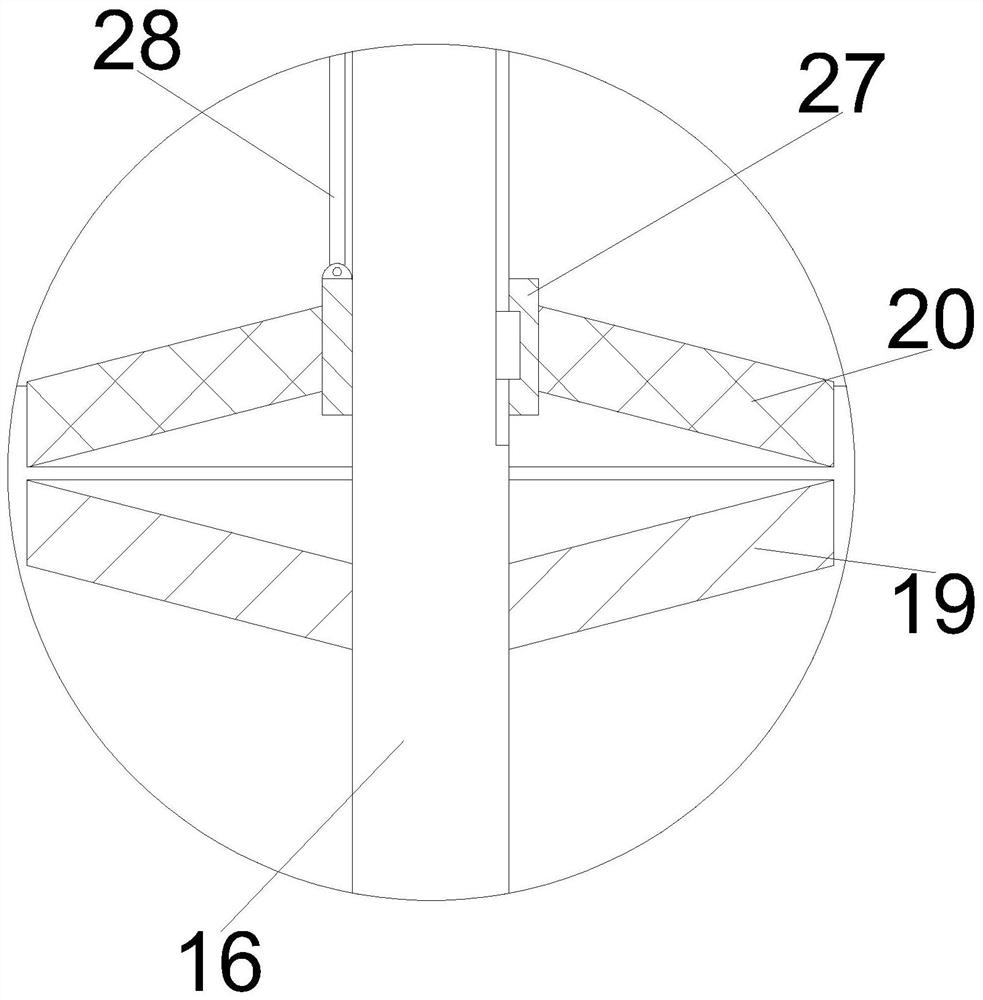

[0034] The diameter of the separation chamber 22 is smaller than the diameter of the water inlet chamber 12, the top of the separation chamber 22 and the bottom of the water inlet chamber 12 are connected with a main shaft 16, and the outer surface of the main shaft 16 is keyed with a shaft sleeve 27, and a tapered filter plate 20 Fixed on the sha...

specific Embodiment 2

[0047] Specific embodiment two: different from specific embodiment one, please refer to Figure 7 A kind of microplastic separation device, comprises collecting filter plate 43, and collecting filter plate 43 replaces backing plate 19 and conical filter plate 20, and collecting filter plate 43 is fixedly arranged on the axle sleeve 27, and the bottom end of collecting filter plate 43 is inverted Conical surface, the collection filter plate 43 is provided with an inverted cone cavity 47 with an upward opening, the bottom of the inverted cone cavity 47 is an inverted cone surface, and the bottom of the inverted cone cavity 47 is fixed with a connecting pipe 46, which extends downward to the collection The lower side of the filter plate 43 and the lower side of the collection filter plate 43 are provided with a collection box 44, the top of the collection box 44 is fixedly connected with the bottom ends of the two communication pipes 46, and the collection box 44 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com